Wood in civic buildings

Image © Urban Arts Architecture

The residential floors are constructed in light wood frame, a highly efficient building system that utilizes a renewable material, harvested from sustainably managed forests. Solid sawn lumber is also inherently low in embodied energy.

All of the apartments have abundant natural light and access to generous balconies and in many cases, panoramic views of the city. The common roof terrace has both a children’s play area and large planter boxes that serve as a community garden, accommodating the City of Vancouver’s urban agriculture mandate and giving tenants an opportunity to contribute to their own well-being.

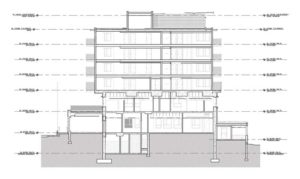

Just as this project broke new ground in terms of its mixed-use program, it also posed structural engineering challenges not dealt with in the current B.C. Building Code (BCBC). Although Herold Engineering had considerable experience with both fire halls and multi-storey, light wood-frame construction, there were no precedents to guide them through the design of a hybrid structure of this type that was also required to perform to post-disaster standards.

In such circumstances, the engineer-of-record is required to consult with professional peers to confirm the validity of the design assumptions being made. In concert with the City of Vancouver, an independent technical review was undertaken and design parameters agreed on before the final structural design phase.

While the decision to construct the fire hall portion in concrete was made at the outset of the project, the material of choice for the residential floors was reviewed with several options being put forward for cost analysis. Cross-laminated timber (CLT) and steel were both considered, but with each iteration of the design, the consulting team returned to traditional light wood frame as the most flexible and economical choice.

Creating a hybrid structure that behaves harmoniously under seismic, wind, and other dynamic loads is a challenge when the concrete spans are long, such as in a fire hall. This is in contrast to the more common situation of a commercial podium or parking garage, where the close spacing and repetition of column and beam elements enables imposed loads to be distributed more evenly throughout the podium structure. Additionally, the overall height restriction meant floor-to-floor heights on all levels had to be minimized to ensure the required residential program could be accommodated. A further complication was the need to provide three large apparatus door openings in the north wall, limiting the number of columns that could be used.

Image © Johnston Davidson Architecture

To create consistent diaphragm action at the third-floor level at the base of the wood frame structure, the concrete slab was strengthened with a series of integral down-stand ‘joists’ that also help transfer loads evenly. These joists also provided the additional thickness necessary to cast in the multitude of screw anchors required to hold down the light wood building above, against seismic and wind uplift loads.

Additionally, because of the long span, there was a requirement to cast the 18- and 17-m (55-ft) slabs over the fire hall with a crown in the centre, in anticipation of the deflections occurring during construction and over time. This posed challenges for the four-storey, common wood-frame construction with gypsum board paneling being erected above the slab.

Comparing the predictions from several analytical software applications, the decision was made to camber the slabs accordingly and to monitor deflection during construction. Shims were used to level the prefabricated light wood-frame wall elements as they were installed. As construction proceeded, measurements were recorded confirming deflection of the long span suspended slabs was small enough to avoid excessive cracking in finishes.

Vancouver is in a very high seismic zone, so considerable analysis and design is required to ensure fire hall structures meet the building code requirements for post-disaster use. As this building makes use of wood framing for the four-storey residential portion, the wood structure makes use of conventional 2×6 frame construction with single- and double-sided plywood-sheathed shear walls along the corridors, at demising walls between suites, and for bearing walls within each suite. The higher than usual number and cumulative length of shear walls and seismic tie downs were needed to meet the more rigorous code requirements for this type of building.

Concrete and wood frame have decidedly different ductility and over-strength parameters, which are predictors of performance in a strong earthquake. After much consideration and professional peer reviews, it was decided to modify the wood-frame ductility and over-strength co-efficients to rationalize the requirement for force resistance between the two distinctly different framing systems.

The floor structure on levels four through six comprises wood I-joists and, where loads are greatest, laminated veneer lumber (LVL) beams. In the third-floor common room, where spans are greatest, steel beams were used in concert with wood beams and joists. These measures were required because

of the height restriction noted previously. This limitation also required the elimination of suspended ceilings and the careful routing of mechanical ductwork through and between the I-joists.

The use of hydronic heating also added complexity, as the 50-mm (2-in.) concrete topping on each floor added to the dead weight of the building and also to the magnitude of the lateral forces that had to be resisted and resolved.

At roof level, the provision of a play area in the centre portion of the roof required the mechanical units to be located around the perimeter, rather than positioned directly above the zone of the building they served. As a result, additional lengths of ductwork were required to connect the units with the appropriate zone below, and the structural engineer and I-joist manufacturer worked collaboratively to optimize wood-frame layouts.

The success of this highly innovative project is, in part, due to the adaptability and affordability of contemporary light wood-frame construction. Faced with height restrictions, post-disaster seismic requirements and unusual loading conditions, it nonetheless proved the most viable choice for the residential portion of the building.

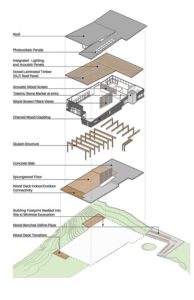

Radium Hot Springs Community Hall and Library

The Village of Radium Hot Springs is located in the Columbia River Valley, East Kootenay region of southern British Columbia. The area is known for the natural hot springs in nearby Kootenay National Park, the Columbia Valley wetlands, and the Rocky Mountain culture. Perched on the edge of a natural kettle hole and lined with pine trees, the site of the new 800-m2 (8611-sf) community hall and library is a microcosm of the valley. Vancouver-based Urban Arts Architecture (UAA) was selected to design the project following a request for proposals (RFP) issued by the village.