Wood-framed Floors Beyond Code: The importance of balancing design trends, product choices, and installation methods

by Tomo Tsuda, P.Eng., PE, and Tammi Rebman

When designing a wood-framed floor system for multi-family projects, building to meet the prevailing building code is only the first step in the performance spectrum. Once complying with those requirements, there remains an array of choices a designer can make without materially affecting the project’s overall cost that nonetheless directly affect occupant comfort and the floor’s perceived quality.

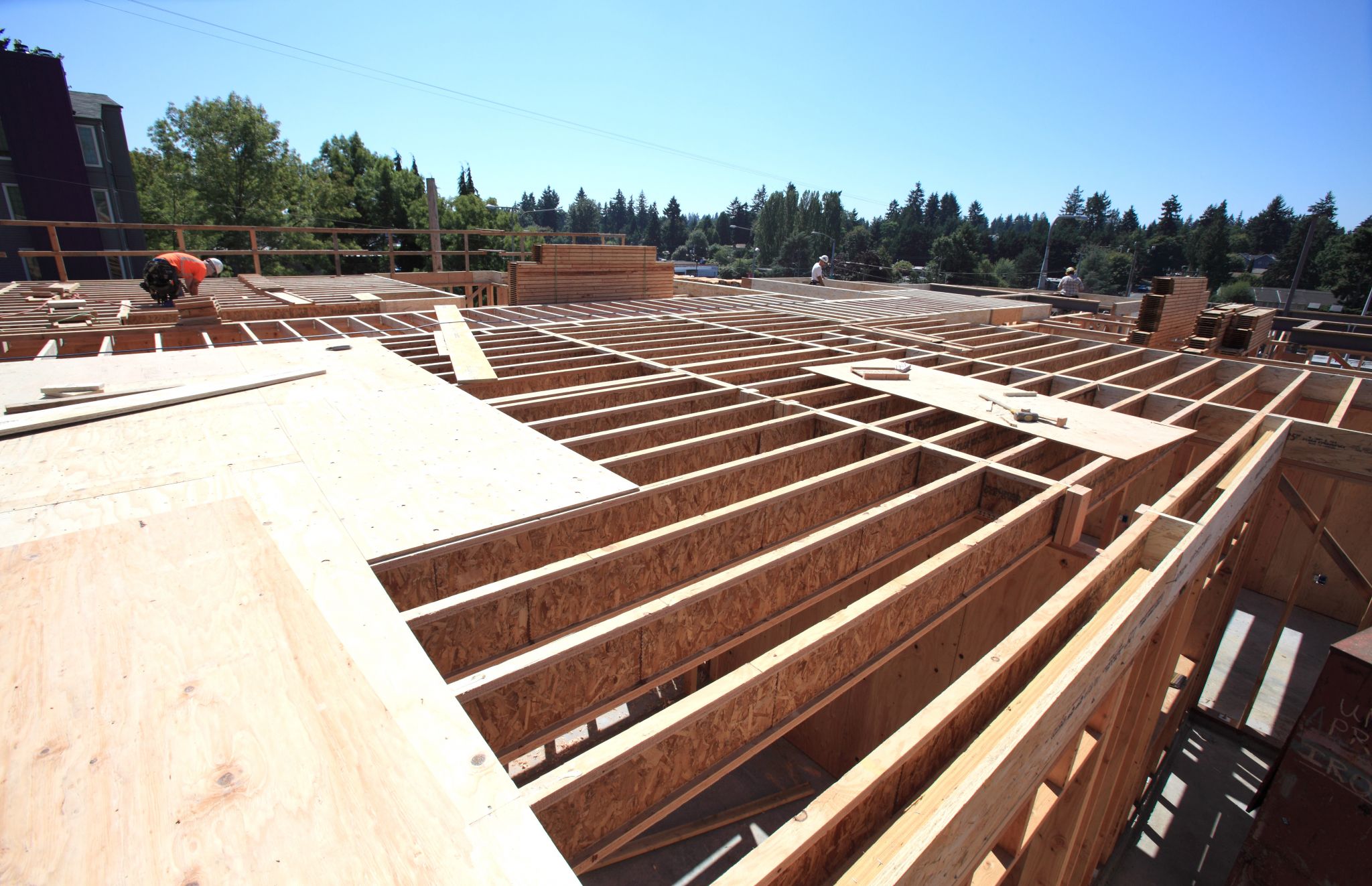

When selecting materials for wood-framed multi-family projects, engineered lumber products such as I-joists, laminated veneer lumber (LVL), and laminated strand lumber (LSL) contribute to a structurally sound, code-compliant floor, including offering consistency of materials and strength to span greater distances and support heavier loads. However, due to their inherent consistency, these engineered products can also be engineered as a system that can play a key role in floor performance. The size and depth of I-joists and related framing members, and their on-centre (oc) spacing, as well as the thickness of the subfloor and the manner in which they are installed, directly influence how stable the floor will feel and perform over time.

As a result, taking the time to consider the floor as a ‘system solution’ and part of the project design, beyond simply complying with code requirements, can contribute directly to occupant satisfaction and their perceptions of overall quality. This dynamic is even more critical as code authorities begin to expand wood-framed construction, allowing six-storey construction in some markets.

Fortunately, designing engineered wood systems that overcome such challenges is fairly straightforward, provided they are addressed collaboratively and early on in the design stage. Software tools and manufacturer consultation can identify options and generate recommendations for product and design specification to help specifiers balance the level of floor performance versus budgetary expectations.

This article outlines the physics behind floor vibration, identifies problem areas where perceived movement is most likely, and examines strategies for avoiding performance issues.

Assessing the challenges

Perceptions of unacceptable floor performance have challenged designers for years. Even after meeting Canadian Vibration Criteria (part of the National Building Code of Canada [NBC], it essentially sets standards for the ‘frequency’ and ‘amplitude’ of vibration in a floor), normal working loads from the movement of occupants sometimes result in floor motions considered annoying by others. This can occur even on floors where design loads are extremely large compared to the forces generated by a person walking. Certain trends in building design, such as open floor plans, can amplify the perception of floor performance issues.

Manufacturers have investigated performance issues for floors framed with joists and structural composite lumber (SCL) products. In one case, extensive floor performance survey results were linked with research and theory to the perceptions of floor users. The results of this research can aid specifiers in determining which factors are most likely to contribute to performance, and how to make adjustments based on a balance of performance and cost.

However, it is first necessary to examine the physics behind the problem—the fundamental dynamic properties and their relative effects on a floor.

Frequency

Research has shown most people agree low frequencies, particularly in the range of 8 Hz or less, are uncomfortable. By adjusting the floor system details, it is possible to raise the frequency of a floor system to a level more acceptable to most people.

Amplitude

Large floor movements are generally more noticeable, regardless of frequency. Amplitude increases with span.

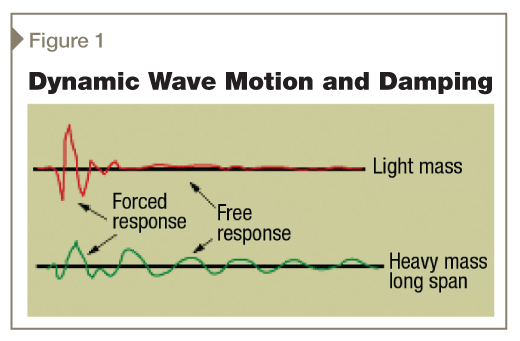

Damping

If the wave motion caused by a moving load rapidly reduces, the movement is less noticeable regardless of frequency and amplitude. Damping increases with the addition of a ceiling or with a solid partition transverse to the joists. Adding mass reduces damping. Typical dynamic wave motions and damping related to mass are shown in Figure 1.

The addition of a poured topping on the deck increases the floor’s transverse stiffness, which is a positive effect. The added mass, however, decreases damping, which can have a negative effect. An appropriate method of accounting for these contradictory effects is still being investigated.

Assembly components

Various floor assembly components will affect a floor’s performance.

Basic stiffness

A combination of joist depth and span, greater basic stiffness increases frequency and assembly stiffness. For a given span, increasing the joist depth results in the greatest increase in basic stiffness.

Joist spacing and deck stiffness

Reduced joist spacing or increased deck thickness generally improves floor performance by increasing assembly stiffness.

Composite action

‘Composite action’ is a measure of how the assembly’s deck component interacts with the joist to effectively increase basic stiffness. Increasing stiffness (i.e. thicker deck) and/or use of construction adhesives increases composite action for short-term dynamic loads.

Continuity

Joists continuous over several supports generally enhance floor performance because a joist in a continuous span would deflect less than the same joist in a simple span application. Care must be taken if such joists continue into an adjoining occupancy as these members can transmit vibration and sound through the floor assembly.

Ceilings

A directly applied (not suspended) gypsum ceiling or strapping—minimum 1×4 applied flat to the joist at 1.5 m (5 ft) oc or less—improves floor performance. Assembly stiffness and damping are slightly increased.

Bridging/blocking

Bridging/blocking and strapping properly installed at 2.4 m (8 ft) oc or less enhance floor performance. (It is important to check local codes for interval requirements.) Bridging/blocking and strapping should be continuous from wall to wall (or support beam) and evenly spaced along the floor span. When there are interruptions from HVAC equipment—such as a duct running parallel to the joists in the floor cavity—or changes in joist depth, there must be proper consideration for detailing.

Beams

When joists are supported on beams, there is a small increase in deflection under normal working loads, which slightly reduces floor performance. Beams designed for relatively large tributary floor areas have less effect.

Additional contributing factors

Full-height framed partitions that are transverse to the joist and away from supports have the effect of damping vibrations, which improves floor performance. However, such partitions must be solidly connected to the floor assembly.

It is important to remember a floor assembly deflects even under light working loads. Bridging that splits during installation, and ductwork that rubs against joists, can produce noise that may reduce the floor’s perceived quality.

The most effective and economical technique for ensuring good floor performance is the identification of the proper depth, series, and spacing for the joist during the design phase. A deeper, stiffer joist is the most economical solution for increasing floor performance for a given span.

Problem areas driven by design trends

Assuming the floor system meets building code requirements and vibration criteria, there are several common problem areas that will be likely candidates additional engineering to eliminate deflection.

For example, many low- and medium-rise condominium buyers, or townhouse owners, desire open-floor plans and expansive great rooms. Engineered wood allows for the longer spans that can eliminate bearing walls and columns, opening up rooms and preserving sightlines. However, with those longer spans comes an increased likelihood of ‘bouncy’ floors.

A similar situation arises in single-family home basements: While typically unfinished when new, many buyers want the option of finishing and subdividing the space later, and load-bearing walls get in the way of their plans.

Long spans next to short spans

In a room with long-span I-joists parallel to short spans, the occupant may perceive the floor to be more solid in the areas with the short spans. To accommodate these differences in floor performance, designers can tighten the spacing of the joists or use stiffer joists.

Joists used to their maximum spans

When reaching the maximum strength or deflection limit for a certain joist, the floor system may be economical and strong enough, but it also may undergo more deflection or bounce than expected. Depending on the client’s expectations, it may be better to consider a stiffer floor assembly, and evaluate the effect on performance to make the best system choice.

Long spans combined with higher dead loads

Another noticeable trend is the increasing frequency of large islands with heavy countertops. As the kitchen continues to be the core of a family’s living space, the island increasingly serves multiple duties as not only the centre for dinner preparations, but also for dining, homework, and entertaining.

The combination of size and weight is a recipe for floor deflection and poor performance; the added load can adversely affect vibration, which will not only feel bad underfoot, but can also shake cabinets and their fragile contents. A focus on increased floor stiffness in this area can be a wise investment.

To reduce the possibility of unacceptable vibration, the size of members under the dead load can be increased or spacing tightened up—even when the code allows for wider layout.

Performance versus cost

While it is desirable to obtain the highest possible rating for all floors, there are always economic considerations. Proprietary software tools available from a leading engineered wood manufacturer can help specifiers determine a floor system design that offers optimal performance balanced against monetary concerns. Such tools account for the unique variables that affect performance to determine an appropriate floor system rating; the program can also list the components required to reach that rating. It considers the floor assembly in addition to joist stiffness to rate the performance.

The rating system can be targeted to different client preferences, or even to individual areas of the floor, taking into consideration how different rooms will be used and occupied. For example, a condo’s rec room designed for entertaining might be weighed separately from the dining area or kitchen. Other considerations include whether floor performance of rental apartment units should be considered from the same viewpoint as those in expensive condominiums. (This might depend on the size of the rental units and the target market.)

The system gives designers a comparison cost value based on the volume of engineered floor joists in the assembly. (This is not precise, but it gives a reasonable relative number.) Some experimentation with varying the assembly’s components offers the designer a good feel for how to obtain the best value in the assembly, from both cost and performance rating standpoints. For example, depending on building details, it may cost little to increase joist depth. In other cases, a smaller joist section at reduced spacing may be the best choice.

Installation considerations

Along with product specification considerations, the floor system’s actual installation plays a significant role in overall performance related to occupant comfort. Framing contractors should adhere to the following standards to reduce the chance for squeaky floors.

Floor system

For the floor system, all subflooring fasteners must hit the supporting joist members, with all supports solid and level. Hangers, when used, must be installed in accordance with manufacturer’s instructions.

Subflooring

Oriented strandboard (OSB) and plywood subfloor panels should be spaced with a 3.2-mm (1/8-in.) gap at all edges and ends—this accounts for naturally occurring expansion, avoiding buckling. Many premium floor panels have tongue-and-groove edges designed to self-gap.

Wet lumber can lead to dimensional changes as the joists dry, resulting in nail pops and floor squeaks. Wood subfloor panels should be allowed to dry if they get wet, especially if installed under sensitive finish materials such as hardwood.

To avoid nail pops, pullouts, and shiners (all of which can cause squeaks),1 the correct nail size and spacing must be specified, ensuring the nails penetrate the floor joists and sink fully. Both local regulations and the expertise of the manufacturer should be consulted.

It is also important to remember glue-nailed construction techniques are optimal for ensuring a flat, stable floor. Again, one should select and apply adhesives per manufacturer instructions and building code requirements.

Conclusion

ven when built to code, many engineered wood floor systems still have room for performance improvement that can reduce the likelihood of deflection and subsequent occupant discomfort. Design choices upfront—such as joist spacing, stiffness, or continuity—can significantly affect the floor system performance. ‘Performance-focused’ design utilizing software and balancing economic factors, combined with reasonable care during installation, can help avoid potential occupant dissatisfaction down the road.

Notes

1 A ‘shiner’ is a nail that barely hits the joist. (back to top)

Tomo Tsuda, P.Eng., PE, is an engineer for codes, standards and product engineering with Weyerhaeuser Trus Joist. He has worked for Weyerhaeuser for 17 years, including a decade in Japan. Tomo is a licensed civil engineer in British Columbia and Idaho. He can be reached at tomo.tsuda@weyerhaeuser.com.

Tomo Tsuda, P.Eng., PE, is an engineer for codes, standards and product engineering with Weyerhaeuser Trus Joist. He has worked for Weyerhaeuser for 17 years, including a decade in Japan. Tomo is a licensed civil engineer in British Columbia and Idaho. He can be reached at tomo.tsuda@weyerhaeuser.com.

Tammi Rebman, P.Tech. (Eng.) has been an engineered wood products designer with Weyerhaeuser SC Ltd. for the past five years. Over the last 14 years, she has been designing floor and roof systems for single-family homes, multi-family projects, and light-commercial buildings in Western Canada. Rebman graduated from the Northern Alberta Institute of Technology (NATIT) in 2000 with a diploma in civil engineering, and obtained her P.Tech (Eng.) designation within Alberta last year. She can be reached at tammi.rebman@weyerhaeuser.com.

Tammi Rebman, P.Tech. (Eng.) has been an engineered wood products designer with Weyerhaeuser SC Ltd. for the past five years. Over the last 14 years, she has been designing floor and roof systems for single-family homes, multi-family projects, and light-commercial buildings in Western Canada. Rebman graduated from the Northern Alberta Institute of Technology (NATIT) in 2000 with a diploma in civil engineering, and obtained her P.Tech (Eng.) designation within Alberta last year. She can be reached at tammi.rebman@weyerhaeuser.com.