Wind design for modular vegetated roofing systems

Wind design process of vegetated roofing assemblies using CSA A123.24

The significance of CSA A123.24-15 is it determines the resistance of the MVRA. This enables designers to compare the resistance to the design values and determine if an assembly is secured against the wind uplift for a specific project by following a few simple steps.

Step 1

Determine the project’s design wind load (PD) and the design wind speed (VD) using the National Building Code (NBC) or the Wind-MVRA online calculator at www.nrc-cnrc.gc.ca/eng/services/windrci.

Step 2

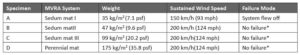

Request the wind uplift resistance (PR) and the wind flow resistance (VR) of the modular vegetated roof assembly, as determined per CSA A123.24-15 from the green roof supplier.

Step 3

The MVRA is secured against wind forces for the project if the following conditions are met:

- wind uplift resistance (PR) is higher than the design wind load (PD); and

- wind flow resistance (VR) is higher than the design wind speed (VD).

The Wind-MVRA is a useful online tool for wind design of modular vegetated roof assembly that is developed and maintained by NRC. The designer inputs the building specifics (location, dimensions, exposure, opening, and importance category) and the program outputs the design wind load (PD) and design wind speed (VD) based on data from NBC 2015.

Since the resistance depends on pressure equalization, which can vary with many factors, such as vegetation growth, moisture content, and permeability of the MVRA, it is critical to test the MVRA for resistances and go through the wind design process to ensure the green roof is secured against uplift (See “More Notes on CSA A123.24”).

Conclusion

Like any building envelope component, vegetated roof assemblies must be designed properly to resist wind forces to ensure durability and public safety. Designers should follow best practices from existing guidelines. CSA A123.24-15 provides a means to determine the wind resistance of modular vegetated roofs. Engineers should ask green roof suppliers for the wind resistance of their systems and follow the wind design process to select the appropriate assembly for their projects. Alternatively, some green roof suppliers retain professional engineers to perform the wind design process on behalf of their clients.

Karen Liu, PhD, is a green roof specialist at Next Level Stormwater Management (NLSM). Before joining the private sector, Liu was a lead researcher of the green roof programs at the National Research Council Canada (NRC) and the British Columbia Institute of Technology. In recent years, Liu was a key participant in the research consortium that developed the first national wind testing standard for vegetated roofing, the Canadian Standards Association (CSA) A123.24-15, Standard Test Method for Wind Resistance of Modular Vegetated Roof Assembly. Additionally, she has vast practical experience having worked on hundreds of green roof projects across North America, Europe, and Asia. At NLSM, Liu worked on special projects and wind and stormwater calculations. She can be reached at karen@nlsm.ca.