Why All Roads Lead To Concrete: Paving for economy and the environment

Another consideration is the volume of granular base/sub-base materials needed to provide structural support for the pavement. Due to concrete’s rigidity and stiffness, the slab itself supplies a major portion of its structural capacity and distributes heavy vehicle loads over a relatively wide area of sub-grade.

An asphalt pavement is not as rigid and does not spread loads as widely. Therefore, these pavements usually require more layers of base granular material at a greater thickness, when compared to an equivalent concrete pavement design. (Refer to ACPA’s EB204P, “Subgrade and Subbases for Concrete Pavements” [2007].) Based on an analysis performed on equivalent pavement designs for asphalt and concrete pavements for an arterial road on a low-strength sub-grade, about 50 per cent more granular material can be needed for an asphalt pavement structure than for a concrete structure. (See Applied Research Associates’ Pavement Engineering Technical Services Equivalent Pavement Designs: Flexible and Rigid Alternatives [2003].) Environmental effects of this increased demand on granular material may amplify if suitable aggregate sources are not locally available.

Reduced energy demand

Concrete surfaces readily reflect light. This characteristic of concrete—generally referred to as albedo—is advantageous for several reasons. It can significantly improve both pedestrian and vehicular safety by enhancing nighttime visibility on and along concrete roadways. Consequently, concrete’s albedo reduces the amount of energy needed for artificial roadway illumination during the night. It also lowers the energy necessary to cool urban environments, and diminishes potential for smog formation.

Paving urban roadways with concrete is an effective strategy to help mitigate urban heat island (UHI) effects. Due to their higher albedo, concrete pavements will reflect significantly more sunlight and are cooler than asphalt pavements. In the United States, Lawrence Berkeley National Laboratory (LBNL) research suggests on exposure to sunlight, most lighter-coloured concrete pavements will have surface temperatures approximately 12 C (22 F) lower than darker-coloured asphalt pavements. (Refer to M. Pomerantz et al’s “The Effect of Pavements’ Temperatures on Air Temperatures in Large Cities,” Lawrence Berkeley National Laboratory Report LBL-43442 [2000].)

A report comparing the environmental impacts of concrete pavements to asphalt pavements indicates the latter require more light per unit length to achieve the same illumination as the former. (See J.W. Gadja and Martha Van Geem’s “A Comparison of Six Environmental Impacts of Portland Cement Concrete and Asphalt Cement Concrete Pavement,” Portland Cement Association, PCA R&D Serial No. 2068 [1997].) The results suggest cost savings of as much as 31 per cent in initial energy and maintenance costs for lighting concrete pavements versus lighting asphalt pavements.

Reduced vehicle fuel consumption and emissions

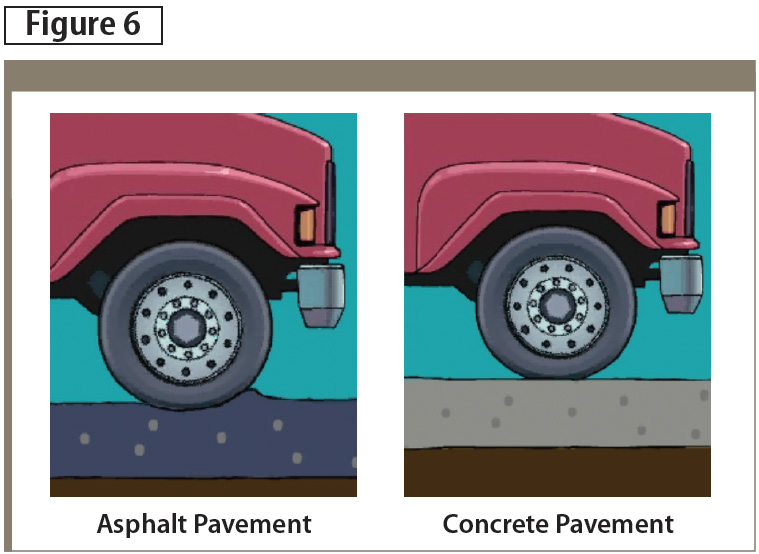

Fuel consumption is partly a function of the degree to which pavement deflects in response to the load applied as the wheels of vehicles traverse the surface. Any deflection absorbs energy that would otherwise be available to propel the vehicle forward (Figure 6).

Several studies to date suggest resistance (i.e. amount of deflection) encountered by heavy-vehicle wheels on asphalt pavements is measurably greater than the rolling resistance on concrete pavements. Thus, more energy and fuel are required to move heavy vehicles on asphalt pavements. (Refer to Taylor Consulting’s “Additional Analysis of the Effect of Pavement Structure on Truck Fuel Consumption,” Action Plan 2000 on Climate Change, Concrete Roads Advisory Committee [Government of Canada, 2002].)

In 2007, the Cement Association of Canada (CAC) completed a case study to determine potential fuel savings and emission reductions achievable if a 183-km (114-mi) stretch of Ontario’s Highway 401 between Toronto and London was paved in concrete. The research used findings from a 2002/2006 National Research Council Canada (NRC) study and 2005 Ontario Ministry of Transportation traffic data. According to the results, more than 70 million L (18 million gal) per year of diesel would be saved, which would avoid 193,132 tonnes of carbon dioxide entering the environment annually. (See Cement Association of Canada’s “Concrete Thinking in Transportation Solutions” [March 2007].)

A number of new studies on the effect of lighter vehicles are also being completed. One study, now available from Sweden, demonstrates concrete pavements save passenger car and light vehicle fuel. The measurements show 1.1 per cent less fuel consumption on concrete pavement compared to asphalt. (See Per Jonsson and Bengt-Ake’s Measurement of Fuel Consumption on Asphalt and Concrete Pavements North of Uppsala [Swedish National Road and Transport Research Institute, 2008].)

Therefore, differences in fuel consumption as a function of pavement type should be an important consideration for government agencies analyzing potential structures for new or reconstructed pavements. Significant reductions in greenhouse gases and fuel cost savings can be realized by choosing carefully.

Paving the Way: Resources and Tools

Produced by the American Concrete Pavement Association (ACPA), ‘StreetPave’ is the latest in concrete thickness design software for streets and local road pavements. The software utilizes proven engineering analysis to produce optimized concrete pavement thicknesses for municipal streets and roads (i.e. collector, minor, or major arterial). A ‘life cycle cost analysis’ module enables design/construction professionals to perform detailed analyses, helping them make informed decisions on pavement design projects.

‘CANPav’ is another concrete pavement tool designed to offer the specifier and owner an easy initial cost comparison through material cost and design inputs. Developed by the Ready Mixed Concrete Association of Ontario (RMCAO) in collaboration with Cement Association of Canada (CAC), this program is online starting this month, and available to anyone interested in comparing the initial construction costs of different pavement alternatives. Visit www.canpav.com.

Conclusion

Concrete pavements last longer than any other type of pavement. They also reduce emissions and greenhouse gases. In terms of initial and long-term costs, concrete pavements are again the best choice. Essentially, in terms of longevity, sustainability, and economics, concrete pavements outperform their counterparts.

Sherry Sutherland, M.A.Sc, P.Eng., LEED AP, is a technical engineer with the Ready Mixed Concrete Association of Ontario (RMCAO) and represents the province’s concrete industry in advocacy, technical, marketing, environment, and education. Prior to joining RMCAO, she was a technical services representative for St. Marys Cement where she gained extensive experience in the cement and concrete industries. Sutherland is currently past-president of the American Concrete Institute’s (ACI’s) Ontario Chapter. She can be contacted via e-mail at ssutherland@rmcao.org.