Why All Roads Lead To Concrete: Paving for economy and the environment

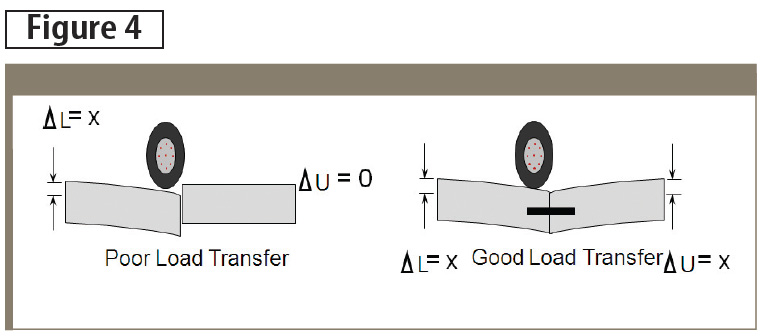

For jointed concrete pavement (plain or dowelled) to perform adequately, traffic loadings must be transferred effectively from one side to another. Adequate load transfer results in lower deflections, which reduces faulting, spalling, and corner breaks, while increasing pavement life. Where aggregate interlock may be insufficient by itself for good pavement performance—like in the case of heavy truck traffic—dowels should be used. Repeated joint deflections caused by truckloads may gradually wear away the aggregate interlock, until it is no longer effective; using dowels ensures long-term load transfer effectiveness. (Figure 4).

Surface texturing

Technology in today’s road design and placement equipment allows owners to specify the ride characteristics of their concrete road. Concrete pavement surfaces are generally textured to provide adequate friction and skid resistance. New concrete surfaces may be textured in many different ways, including various forms of dragged and tined surfaces, and several newer techniques and materials. Each technique can be designed to provide safe, durable, high-friction concrete surfaces. (See ACPA’s “Pavement Surface Characteristics: A Synthesis and Guide,” by Mark B. Snyder, PhD, PE [2006]). Pavement surface texture influences many different tire-pavement interactions, including wet-weather friction, tire-pavement noise, splash and spray, rolling resistance, and tire wear. (See J.J. Henry’s “Evaluation of Pavement Friction Characteristics,” NCHRP Synthesis 291, Transportation Research Board [2000]).

Drag and shallow surface textures are attained by dragging artificial turf or moistened, coarse burlap across the surface of plastic concrete. Tining textures are created by moving a device like a metal rake across plastic concrete. Moving the device parallel to the centreline produces longitudinal tining, whereas movement perpendicular to the centreline is used for transverse.

The combined results from a number of studies completed on pavement noise and/or friction suggest longitudinally tined concrete pavements offer the best mix of consistently low noise, good surface friction, durability, and low maintenance. Asphalt-based pavements are often slightly quieter (initially), but do not consistently provide high friction values. Further, they are subject to rutting, and typically require more maintenance.

Opening pavement to traffic

In accord with Ontario Provincial Standard Specifications (OPSS) 350, Concrete Pavement and Concrete Base, traffic is not permitted on concrete pavement until the material has attained 20 MPa (3000 psi). (Not all provincial regulations are the same; the design team must work with the authority having jurisdiction [AHJ] to remain knowledgeable of the requirements.)

Typically, cylinders are cast and then broken at three days to confirm opening strength. If the project requires the pavement to open sooner than standard concrete allows, ‘fast-track’ concrete mixes can be employed to open traffic in as little as five hours.

Pavements and the economy

For decades, it has always been accepted the initial construction costs of asphalt pavements are lower than that of concrete pavements. However, this perception is changing. For one thing, developments in refining practices will lead to a significant reduction in the future liquid asphalt supply.

New coker refinery processes take the ‘left-over product’ and further refine it into higher-priced items such as diesel, fuel oil, gasoline, and motor oil. Consequently, fewer products are available for bitumen, and its price is increasing globally. The projected rise in costs associated with oil, asphalt, and bitumen, combined with expected shortages, indicates concrete pavements will continue to be more competitive in the future.

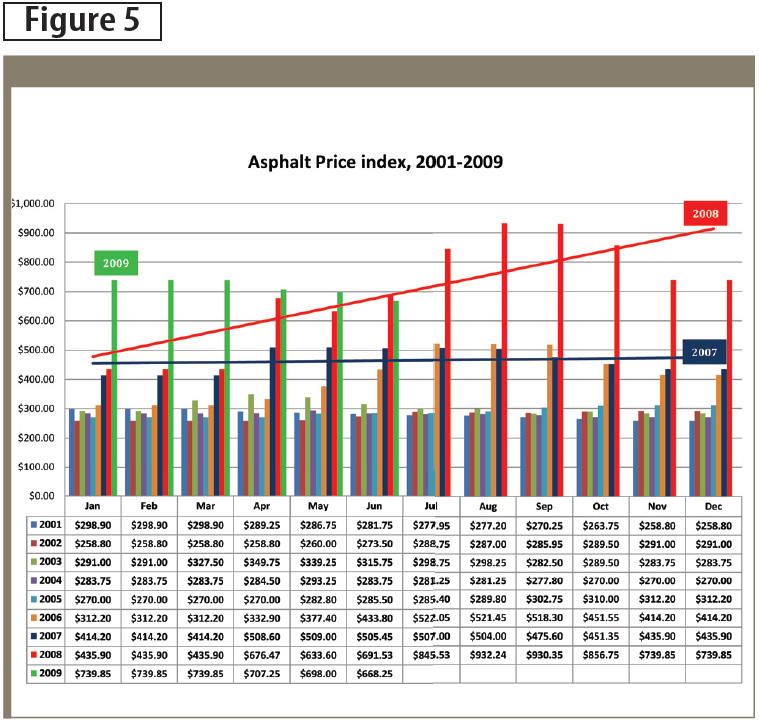

Additionally, asphalt paving costs have risen 148 per cent during the past four-and-a-half years, and fluctuated between an increase of 45 and 113 per cent during the last 20 months (Figure 5). Concrete has not been as severely impacted by the current state of the economy, and continues to provide a more stable price point.

Pavements and the environment

On March 10, 2008, the Government of Canada announced details of their “Turning the Corner Plan,” which is one of the toughest regulatory regimes in the world to cut greenhouse gas (GHG) emissions. Concrete pavements reduce emissions and absolute primary energy, which could significantly assist the government in reaching its target to lower emissions by an absolute 20 per cent from 2006 levels by 2020.

Local municipalities across the country have their own strategies in place to strengthen and protect the environment. Responsible material procurement is a direct way for municipalities to have a great impact and gain taxpayer support.

Concrete’s lower embodied primary energy—131 to 425 per cent, depending on road type—is recognized. A study by the Athena Institute compared embodied primary energy and global warming potential on both asphalt and concrete pavements. The flexible asphalt concrete alternatives were clearly shown to embody more primary energy from a lifecycle assessment perspective than their rigid portland cement concrete counterparts. (Refer to Athena Institute’s “A Life Cycle Perspective on Concrete and Asphalt Roadways: Embodied Primary Energy and Global Warming Potential” [September 2006].)

Recycling and natural resources

As an inert material, concrete is ideal for using industrial byproducts that would otherwise be deposited in landfills—such as slag, which is developed in a molten condition simultaneously with iron in a blast furnace. These industrial byproducts are known as supplementary cementitious materials, and have been used in concrete since the 1970s. They not only divert products from landfill sites, but also enhance concrete’s performance properties.

SCMs are added to concrete as part of the total cementing system. They may be added to, or partially replace, portland or blended cement in concrete—depending on the cementing materials’ properties and the desired effect on concrete. Adding SCMs also reduces concrete’s carbon footprint.

Not all SCMs suitable for concrete are easily accessible in all parts of the country. For example, Canadian sources of fly ash are more readily available in provinces that have coal-burning, thermal-power-generating plants, whereas ground granulated slags are primarily sold and employed in Ontario, which has a significant steel industry.

Concrete itself is 100 per cent recyclable. Crushed concrete can be used as granular fill, base under new pavement, or as an aggregate to strengthen new concrete pavement—all of which reduces the use of non-renewable resources.