Why All Roads Lead To Concrete: Paving for economy and the environment

By Sherry Sutherland, M.A.Sc, P.Eng., LEED AP

Concrete pavements are known for their strength, durability, and longevity. In the past, they have also been associated with a high initial price. However, in a number of lifecycle cost studies, concrete pavements prevail due to the significantly lower maintenance and rehabilitation needs. (See Becca Lane and Tom Kazmierowski’s “Guidelines for the Use of Life Cycle Cost Analysis on MTO Freeway Projects,” Ontario Ministry of Transportation (March 2005). Also see ACPA’s 2002 “Life Cycle Cost Analysis: A Guide for Comparing Alternate Pavement Designs.”)

The initial price still remains at the forefront of owners’ minds, but many do not realize concrete pavements are now competitive on a first-cost basis. The new paving realities are that comparative initial bid cost and lifecycle cost assessments increasingly favour concrete over asphalt in the foreseeable future, essentially allowing municipal owners to eat their cake and have it too. (See “Paving: The New Realities” in Portland Cement Association’s Flash Report [October 14, 2008].)

Public officials across the country are faced with the increasing challenge of managing road assets on a stagnant—or in some cases, decreasing—budget. It is essential that an agency critically evaluates its paving material options and determines the best course of action when spending taxpayer dollars.

Concrete pavement basics

Due to its versatility and durability, concrete is the most widely used construction material in the world. In fact, it is second only to water as the most consumed substance on earth. (Refer to P.C. Aitken’s “Cements of yesterday and today; concretes of tomorrow,” Cement and Concrete Research 1349-1359 [2000].)

Concrete is an inorganic and inert material produced by mixing cement, supplementary cementitious materials (SCMs), water, fine aggregate (i.e. sand), and coarse aggregate (i.e. gravel or crushed stone) with or without various admixtures, reinforcement, fibres, or pigments.

Types of concrete pavements

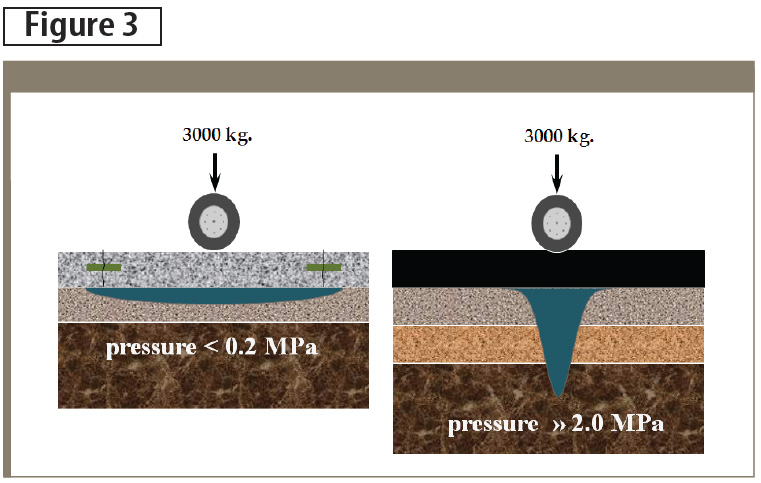

There are three basic design types and each can provide long-lasting concrete pavements that meet or exceed specific project requirements. Jointed plain, jointed reinforced, and continuously reinforced concrete pavements are all suitable for new construction, reconstruction, and overlays of existing roads (Figure 1).

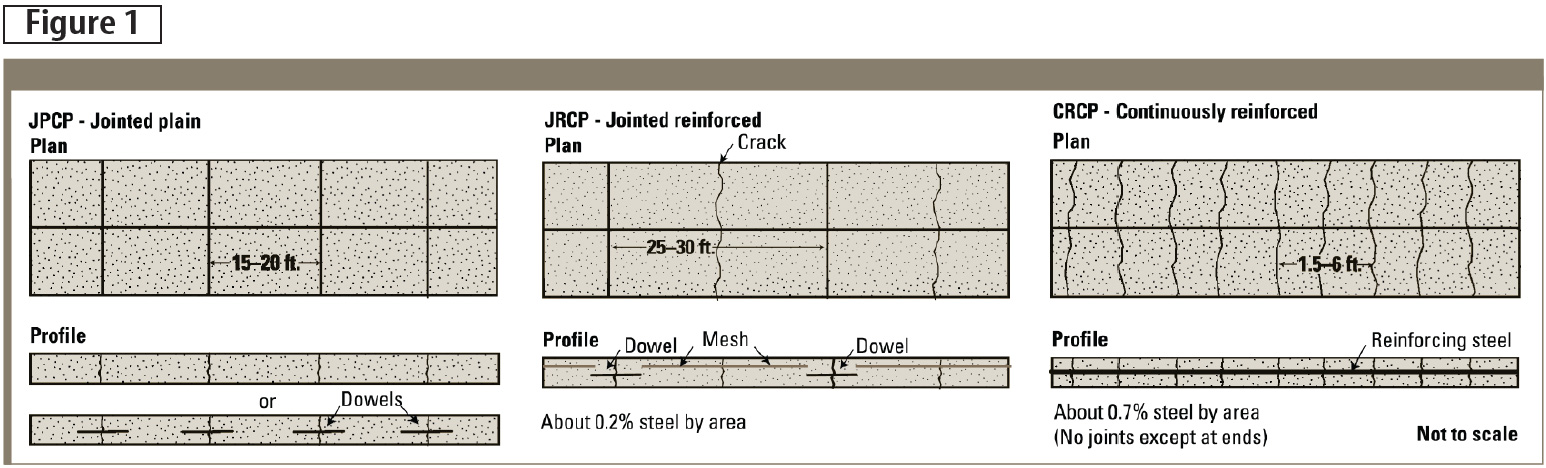

Concrete pavement design involves the development and selection of slab thickness, joint spacing, reinforcement and load transfer requirements, and other pavement features. A pavement designer’s objective is to be economical, while meeting a particular project’s specific needs and conditions (Figure 2).

How pavements carry loads

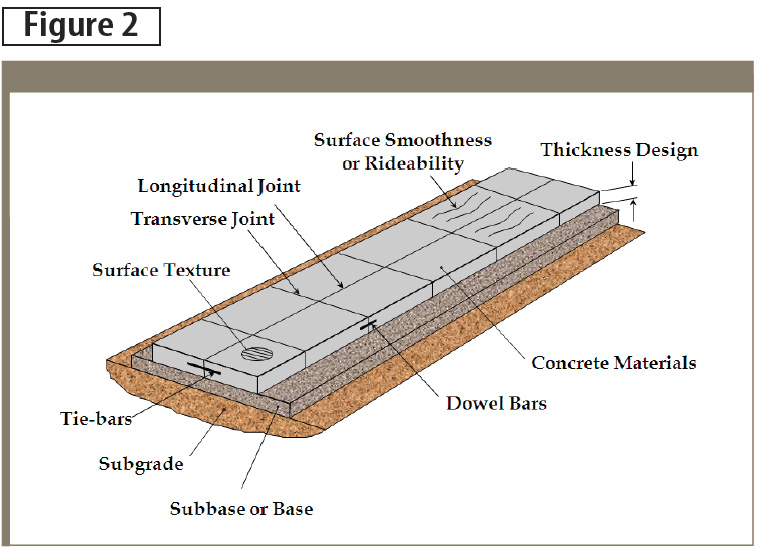

Concrete’s rigidity spreads wheel loads over a large area through the slab and keeps pressures on the sub-grade low. In contrast, asphalt pavements transmit loads deeper, necessitating a thicker base and sub-base. As they require less sub-base material, concrete pavements offer another cost benefit (Figure 3).

Concrete paving mixes are designed to produce the desired flexural strength and give durability under conditions the pavement will face. Typically, a 28-day modulus of rupture between 3.8 and 4.8 MPa (551 to 696 psi) resists cracking from flexural fatigue.

Determination of load transfer at joints

Load transfer is the slab’s ability to share its load with the neighbouring slab, and aggregate interlock refers to the interlocking action between aggregate particles at the face of a joint. Aggregate interlock relies on the shear interaction between aggregate particles at the irregular crack faces that form below the saw cut or formed groove at control joints.