Whitemans Creek Bridge: Accelerating construction with UHPC and FRP

Photo courtesy MTO

Photo courtesy Lafarge

Deck slab connections

UHPC’s outstanding strength allows the width of joints between precast elements to be minimized due to the material’s ability to allow for reduced lap splices in the deck reinforcing. For the transverse joint, the specified 160-mm (6.2-in.) wide opening could have been further reduced; however, from a practical necessity to quickly place the UHPC, a narrower opening would slow the material’s placement. Similarly, the 350-mm (14-in.) wide longitudinal joint specified has enough width to allow for shear stud placement on the girders.

The deck slab consists of 16 pairs (32 total) of precast panels, each 225 mm (9 in.) thick x 2240 mm (88 in.) wide x 7075 mm (279 in.) long. Pockets in the panels were required over the girders for the shear stud connection to them. At the centre girder, there was a continuous longitudinal gap of 350 mm. The slabs were not post-tensioned as the UHPC joint fill provides sufficient durability when combined with asphalt and waterproofing. Additionally, the precast panels were detailed so the need for formwork was eliminated, which greatly contributed to the construction speed.

Before slab erection, 50-mm (2-in.) wide strips of ethylene vinyl acetate (EVA) foam were glued to the top flange’s outside edges to contain the UHPC. The first slab was placed and adjusted to grade via six levelling devices (two at each girder), ensuring proper load distribution of the precast panel to the supporting steel girders. The panel’s weight was used to compress the EVA foam strips, resulting in a leak-proof system.

Photo courtesy MTO

The shear pockets and haunches over the girder flanges were grouted starting at the low end, followed by the longitudinal joint along the bridge’s centreline (Figures 6 and 7). As grouting progressed, plywood forms were placed over the pockets and fastened down to prevent the UHPC from overflowing due to the inherent grade of the bridge, since UHPC is self-levelling. The transverse joints between the precast panels were subsequently placed (Figure 8).

Normal daily productivity for this operation was approximately 12 to 16 m3 (424 to 565 cf), based on a crew of five people and two high-capacity mixers. The 21 m3 (742 cf) of UHPC needed for the bridge deck thus required two days for placement and an additional four days for normal curing (with accelerated curing, this can be reduced to 12 hours).

The approach slabs consist of six precast panels each 250 mm thick x 2079 mm (82 in.) wide x 6000 mm (236 in.) long with 200-mm (7.8-in.) wide joints between the segments. After the abutments reached 20 MPa (2900 psi), the precast approach slab panels were installed on the finely graded subgrade and the joints filled with UHPC (Figure 9). The ends of the approach slabs were detailed with preformed holes to allow the slabs to be connected to the abutments using straight vertical dowels with the annular space also filled with UHPC.

Images courtesy FHWA

Testing and development of UHPC for joint fill

As with any new technology, it is necessary to prototype solutions and conduct full-scale testing before deployment. While UHPC has been around for more than 20 years, its use as a joint fill material in bridge decks is relatively new.

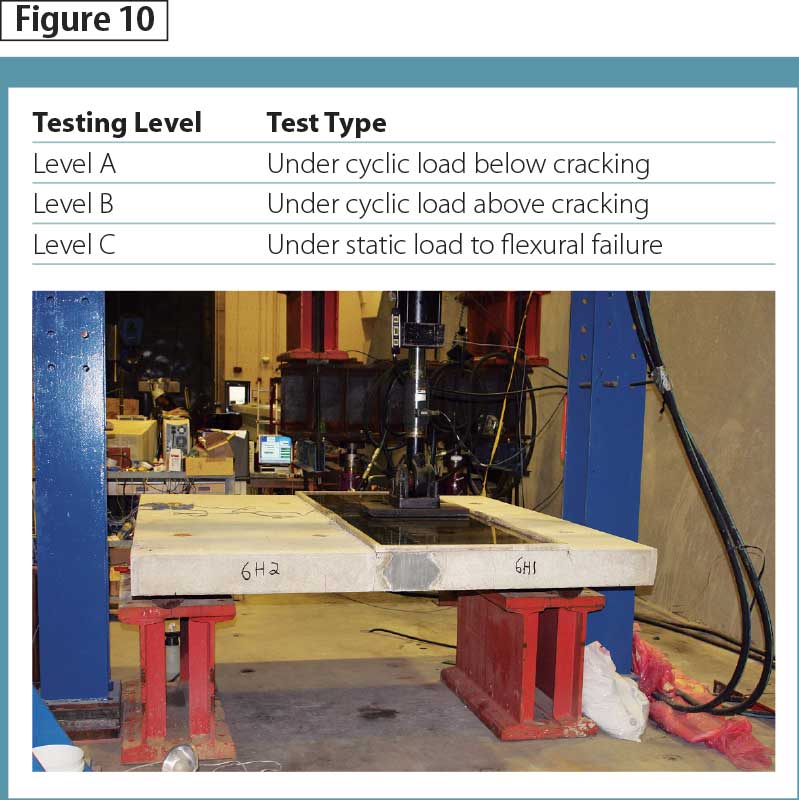

Full-scale cyclic and static loading

FHWA has been actively studying UHPC application in bridge decks for about 12 years. Slab specimens were cast in two pieces and joined together at mid-span by a 150-mm (6-in.) UHPC joint. Various arrangements of 15M bars—some straight, some headed, and some bent—were used to connect the two pieces together. Loads were immediately applied adjacent to the joint, via a 254 x 508-mm (10 x 20-in.) load patch, and tested at three levels (Figure 10).

Under cyclic loading (Levels A and B), there was no interface de-bonding and no leakage through the joint. Under cyclic loading (Level B), a single flexural crack in the concrete became tightly spaced micro cracks through the UHPC joint. Under ultimate loading (Level C), the panel behaved as would be expected of a monolithic concrete slab without any joint or dissimilar materials.

Pullout tests on GFRP reinforcement bars

Testing of UHPC reinforcing’s pullout resistance has been conducted over the last several years to demonstrate the bond characteristics and determine suitable development and lap lengths.

With the introduction of GFRP reinforcement bars, pullout tests in accordance with Canadian Standards Association (CAN/CSA) S6-06, Canadian Highway Bridge Design Code (CHBDC), were performed to obtain approval for using GFRP in the UHPC deck joint fill for specific MTO projects. Pullout test specimens were manufactured with 15-mm (0.6-in.) bar sizes with embedment depths of 100 and 150 mm (4 and 6 in.). Failure behaviour of the pullout test conducted on all samples was delamination between the GFRP’s core and skin (an epoxy sand layer).

Future UHPC applications for bridges

The use of UHPC field-cast connections is a relatively new solution. However, this early adoption has provided excellent field experience and validation of the methodology. It has also meant exposure and confidence in the technology, which has led to innovations for UHPC use for other types of field connections for precast bridge systems, which MTO will consider for future projects.

Photo courtesy Lafarge

Field-cast connections for precast waffle deck panels and hidden shear pockets

UHPC use for precast waffle deck panels (Figure 11) provides a lightweight, durable bridge deck system suitable for new or rehabilitated bridges. Installing UHPC joint fill between the UHPC waffle deck panels provides an entire bridge deck that is made from UHPC. To further reduce dead load and improve the deck durability, the waterproofing and wearing surfaces are removed, thereby leaving the entire UHPC deck exposed to provide the highest durability where it is most needed—at the riding surface.

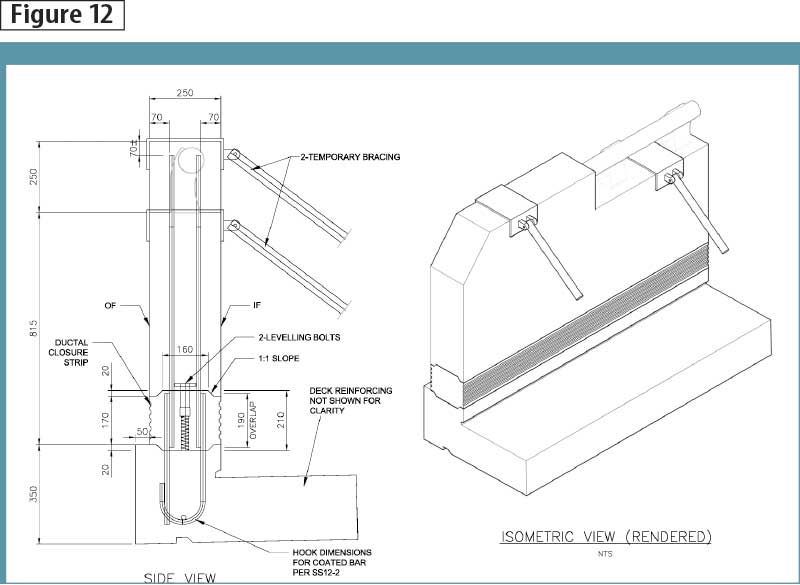

As an alternative to cast-in-place components, precast parapets or barrier walls may be supplied to the bridge already integral with the deck or as separate units (Figure 12) to be field-attached. In both cases, the precast parapet units need to become fully composite with the bridge deck system to carry the traffic barrier loadings. Field-cast UHPC connections for precast parapets and barriers provide integral continuity and further help speed up bridge construction.

Field-cast UHPC for thin-bonded overlays

Another promising use for UHPC field-cast rehabilitation is thin-bonded overlays (or ‘hybrids’) to re-strengthen deteriorating bridge decks. Several state DOTs, co-operatively with universities, are investigating UHPC use as a cost-effective method to significantly extend the life of bridge decks that are approaching their service life.

The use of this system is being investigated as both a field-cast topping for in-situ deck repairs and as a precast system. The precast ‘hybrid’ would be cast top-surface-down where the UHPC is first cast in a textured form liner and then the HPC as a structural backup. Then panels would be cured, flipped, and ready for delivery to the site. The precast hybrid panels would be connected with field-cast UHPC. Hidden shear pockets may also be used with this system.

Image courtesy Delcan

Field-cast UHPC for accelerated bridge construction

UHPC is a family of products where the mix designs can be formulated to provide a wide range of slump flows, hardened mechanical properties, and rate of strength gain. One UHPC product formulated specifically for accelerated bridge construction provides a high early strength of 55 MPa (7980 psi) in 12 hours at normal ambient temperatures. The product has similar fluid workability to other UHPCs and a rapid strength designed for ABC projects that may be executed during weekend closures or other time-limited repairs.

Conclusion

Traditional reconstruction of non-complex bridges typically requires a minimum of four to six months to build, or longer if the bridge work is staged to maintain traffic during construction. Alternately, using accelerated bridge construction techniques or rapid bridge replacement (RBR)—using heavy lift equipment or overnight/weekend construction—reconstruction of a bridge superstructure can be reduced to as little as 48 hours or one weekend. This is typically done in urban areas or on freeways, where the extra cost of using ABC can be easily justified when user expenses—prices associated with public traffic inconveniences (or perhaps even lost job force productivity) combined pointed to the solutions used—are taken into account.

Between these two extremes are options to employ more traditional equipment and maximize prefabrication with the use of UHPC. With a small premium, significant savings in construction duration can be realized. By using ABC techniques, the Whitemans Creek project construction duration was effectively reduced to just seven weeks, with only a 15 per cent premium over traditional methods.

This project also created a unique opportunity for a synthesis of ABC, UHPC, and GFRP. The road closure necessary for the highway reconstruction demanded use of accelerated bridge construction. Incorporating UHPC ensures the joints between precast elements will be durable and can be constructed quickly (i.e. no formwork). Finally, the glass-fibre-reinforced polymer that was used for the top mat deck eliminates corrosion of the top mat reinforcing. By synthesizing all three elements, this project is yet another step toward building more durable structures, rapidly. (The authors would like to thank the Whitemans Creek Bridge project team, which included Ministry of Transportation Ontario (MTO) staff, Delcan Corp., Lafarge Canada, and Dufferin Construction Ltd., for the collaborative partnership throughout the design and construction of this project).

Vic H. Perry, MASc., P.Eng., is the vice-president and general manager for Ductal, Lafarge’s ultra-high-performance concrete. Based in Calgary, he holds a bachelor’s degree in civil engineering and a master of applied science in structural engineering from Dalhousie University (Halifax, N.S.). With 30 years of industry experience, Perry is also a fellow and past-president of the Canadian Society of Civil Engineers (CSCE). He can be contacted via e-mail at vic.perry@larfarge-na.com.

Wade F. Young, M.Eng., is head of the structural section, West Region, for the Ministry of Transportation Ontario (MTO). Based in London, Ont., he has 35 years of industry experience and is a member of the Precast/Prestressed Concrete Institute (PCI). Young can be reached at wade.young@ontario.ca.

Brent I. Archibald, P.Eng., is a senior principal and technical director for Delcan Structures, based in Markham, Ont. Responsible for the technical excellence, quality assurance (QA), and quality control of structure projects in Eastern Canada, he is an alumnus of the University of Toronto (UofT). Archibald is a member of Professional Engineers Ontario (PEO) and the Association of Professional Engineers and Geoscientists of British Columbia (APEGBC). He has 15 years of experience in the engineering, design, and construction of roadway and railway bridges. Archibald can be contacted at b.archibald@delcan.com.