Whitemans Creek Bridge: Accelerating construction with UHPC and FRP

By Vic H. Perry, MASc., P.Eng., Wade F. Young, M.Eng., and Brent I. Archibald, P.Eng.

On bridge projects around the world, delays caused by traffic congestion and detours at infrastructure construction sites have significant impacts on indirect costs. Consequently, there is a need for speed—and a construction method called accelerated bridge construction (ABC). {This article was based on a paper by W.F. Young, J. Boparai, V. Perry, B. Archibald, and S. Salib, entitled “Whitemans Creek Bridge: A Synthesis of Ultra-high-performance Concrete and Fibre-reinforced Polymers for Accelerated Bridge Construction.”)

According to the U.S. Federal Highways Administration (FHWA), ABC is defined as “a paradigm shift in the project planning and procurement approach where the need to minimize mobility impacts, which occur due to onsite construction activities, are elevated to a higher priority.”

Benefits of ABC include improvements in:

- safety;

- quality;

- durability;

- social costs; and

- environmental impacts.

This approach uses safe and cost-effective planning, design, materials, and construction methods to lower the onsite construction time occurring when building new bridges or replacing and rehabilitating existing ones. (For more,, see the Federal Highways Administration’s, “What is ABC?” at www.fhwa.dot.gov/Bridge/ABC).

Photos courtesy MTO

In 2011, the Ministry of Transportation of Ontario (MTO)–West Region completed its first ABC project: Whitemans Creek Bridge, located on a rural, two-lane highway (#24) near Brantford, at the bottom of a curve, within a natural valley with residential property and environmental constraints. By using factory precast concrete elements on the bridge superstructure and substructure, MTO was able to replace the entire bridge within seven weeks instead of several months associated with conventional construction. In conjunction with the precast concrete elements, the use of fibre-reinforced polymer (FRP) reinforcing, along with ultra-high-performance concrete (UHPC) (For past articles on ultra-high-performance concrete (UHPC), see “An Ultra-high-performance Upgrade” by Gaston Doiron, M.Eng., P.Eng., and Kelly A. Henry, M.Arch., MBA, LEED AP, in the December 2011 issue of Construction Canada. Also see “Precast Solution for Performance Cladding: Ultra-high-performance Concrete for B.C. Building” by Don Zakariasen and Peter Seibert, M.Sc., MBA, P.Eng., in the September 2010 issue of Construction Canada. To see the article, visit www.constructioncanada.net and select “Archives.”) for the joints, shear pockets, and haunches, has significantly increased the structure’s performance and durability levels.

The existing bridge—a three-span concrete T-beam structure and a length of 33.5 m (110 ft)—was slated for replacement due to its age, condition, and structural deficiencies. As a result of the site conditions and constraints of the surrounding terrain and residential properties, it was decided to replace the structure using rapid construction techniques.

Photos courtesy Lafarge

The MTO Northwest Region Office in Thunder Bay pioneered the use of UHPC in Ontario. By the end of 2010, they had constructed nine UHPC bridge projects. The first, in 2006, was the CN Overhead Bridge at Rainy Lake, which incorporated precast deck panels with UHPC joint fill (i.e. the UHPC material cast in the field to integrally connect the precast components into a structurally monolithic unit). (For more on the Rainy Lake Bridge, see “Innovative Bridge Decks Field-cast UHPC Joints for Precast Bridges” by V.H. Vic Perry, FCSCE, M.A.Sc., P.Eng., Primo A. Scalzo, M.Sc., P.Eng., PE, and Gary Weiss, P.Eng., MBA, in the September 2007 issue of Construction Canada). Observations made to date indicate outstanding performance. After five years of service in a northern climate, there is neither material deterioration nor any joint opening. (For more, see J. Lee, B. Craig, P. Loh, and V. Dimitrovski’s “Working Toward Maintenance-free Bridge Decks Using Glass Fibre-reinforced Polymer Reinforcing Bars,” from the 8th International Conference on Short and Medium Span Bridges in Niagara Falls, Ont. [2010]).

Since then, MTO Northwest Region has used UHPC joint fill for the interconnection of precast bridge elements, including:

- full-depth precast deck panels;

- side-by-side precast girders;

- full-depth precast approach slabs; and

- precast concrete deck curbs (Figure 1).

During 2010, two Ontario bridges (Eagle River and Wabigoon) used UHPC field-cast joints for live-load continuity over internal piers in precast girder bridges. This joint design (Figure 2) completely eliminated the need for post-tensioning and provided for fast, simple field connections of precast bridge elements.

MTO has also used UHPC field-cast expansion joints as a means to provide strong and durable solutions to solve damage with freeze–thaw degradation, de-icing material, and the constant impact and abuse from trucks and snow ploughs crossing the expansion joints. The use of UHPC for expansion joints eliminates the need for embedded steel edges or cast-in-place concrete between the precast deck and steel embed.

MTO has also built numerous trial projects with glass-fibre-reinforced polymer (GFRP) reinforcement bars, using its non-corrosive properties with the intent of building more durable structures. (See Canadian Standards Association (CSA) S807-10, Specifications for Fibre-reinforced Polymers). The bridge performances are currently being monitored, and testing to date has been very encouraging. Currently, in Ontario, the material cost of GFRP reinforcement bars is about the same as epoxy-coated steel, and about double that of conventional steel when calculated by length.

Due to the low modulus of elasticity of GFRP reinforcing (E ≈ 40–60 GPa [5800 to 8700 psi] versus 200 GPa [29,000 psi] for steel), (For more, see S. Salib’s “Strength of Concrete Beams Reinforced and/or Prestressed with FRP Bars,” a PhD thesis submitted to the Civil and Environmental Engineering Department at the University of Windsor in 2001). crack control in concrete becomes the governing criteria for design. The difference in material properties requires reduced bar spacing as well as increased bar size when GFRP reinforcing is used as the primary tension reinforcing. A bridge deck using only GFRP reinforcing requires an average of 60 to 70 per cent additional reinforcing by length when compared to a similar bridge with steel reinforcing.

The project

The new bridge structure consists of a 40-m (131-ft) single-span steel plate girder structure with a 225-mm (9-in.) thick concrete deck. It measures 14.5 m (48 ft) in overall width and is supported on a single row of steel H-piles made integral with the abutments. To reduce construction time, precast concrete was used for all the reinforced concrete elements, including the integral abutments, with the exception of the barrier wall, which was cast-in-place after the structure was opened to traffic. Durability was enhanced by incorporating two emerging materials into the project—UHPC and GFRP reinforcing.

UHPC has been proven on several projects and is considered by FHWA to be a superior material when used as a joint fill between prefabricated components in bridge decks. (See B. Graybeal’s “Behaviour of Field-cast Ultra-high-performance Concrete Bridge Deck Connections Under Cyclic and Static Structural Loading,” in FHWA’s November 2010 report FHWA–HRT-11-023. Also see V. Perry, P. Scalzo, and G. Weiss’s “Innovative Field-cast UHPC Joints for Precast Deck Panel Bridge Superstructures: In Overhead Bridge at Rainy Lake, Ontario,” from the Precast/Prestressed Concrete Institute (PCI)–FHWA National Bridge Conference from 2007).

The non-corroding property of GFRP reinforcing is being increasingly used by MTO as a measure to build maintenance-free bridge decks.9 In addition to its non-corroding properties, the GFRP reinforcing weight is only about 30 per cent less than steel; this facilitates reduced labour expenses. Also, to achieve an optimal bridge design, GFRP reinforcing was used for the top mat and steel for the bottom, balancing durability and cost.

UHPC joint fill for precast concrete

In terms of durability, construction joints between precast elements have traditionally been the weak link in the system, thus reducing the overall benefits of precast. However, using UHPC to connect precast elements promises to eliminate this issue and, in fact, make the joints the strongest link. For the Whitemans Creek Bridge, UHPC was used to fill the voids between the precast abutments and the H-pile foundations, and in the joints between the precast panels for both decks and approach slabs. All precast elements were constructed using 35-MPa (5075-psi) concrete.

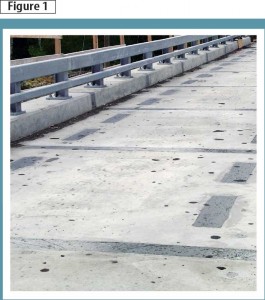

The UHPC technology used for the joint infill is an ultra-high-strength, ductile material (Figure 3) made with:

- portland cement;

- silica fume;

- quartz flour;

- fine silica sand;

- superplasticizer;

- water; and

- steel fibres.

Image courtesy Delcan

The concrete’s ultra-high-strength properties and low permeability provide for excellent reinforcement protection against corrosion and improved bond with the rebar, thereby providing short bond development lengths. The use of fibres in UHPC provides superior durability and crack control by dispersing any strains into well-spaced, tightly closed micro-cracks. For field-cast UHPC, compressive strength specimens for quality control are typically 75 x 150-mm (3 x 6-in.) cylinders tested at 28 days. Field-cast results are typically lower in compressive strengths compared to lab or precast due to mix adjustments for field-batching, hot-weather-batching, and field-curing (as opposed to thermally treated).

While compressive strength tests are used to validate field quality assurance/quality control (QA/QC) during casting operations, it is the short bond development length that governs the design. All UHPC testing for joint fill has been done on specimens with a 100-MPa (14,500-psi) compressive strength to validate minimum strengths for opening to traffic.

The UHPC was batched with a mini-slump flow of 200 to 250 mm (8 to 10 in.) and will slowly self-level and fill voids without using any vibration. To ensure complete joint filling and accommodate the release of any trapped air, a small hydrostatic head of up to 200 mm is maintained. The concrete used is self-consolidating during the material’s initial setting and also exhibits superior durability with the chloride ion permeability (i.e. < 100 coulombs); this is very low compared to the 1000-coulomb permeability specified for high-performance concrete (HPC) in Ontario.

Photo courtesy MTO

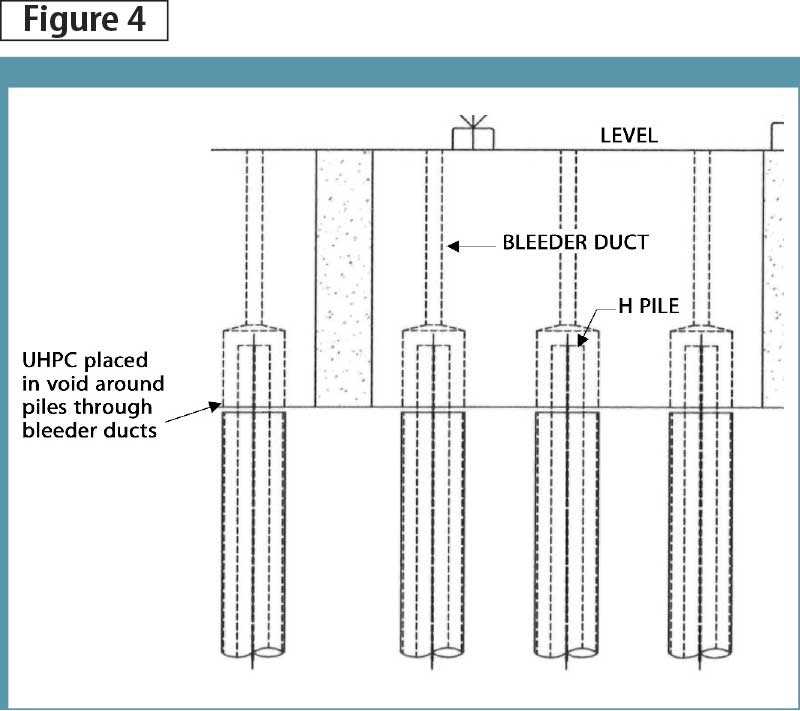

Integral abutment connection

The abutment stem was precast in four sections; the two central and the two outer sections being 3.8 and 2.6 m (12.4 and 8.4 ft) wide, respectively. Since the abutments were precast, and the integral connection required the ability for the abutment to transfer both axial and flexural loads directly into the piled foundation, a suitable connection between the abutment and steel pile foundations needed to be developed. Pockets that were 600 x 600 mm (24 x 24 in.) were formed into the underside of the precast abutments to accommodate the piles and allow for acceptable tolerances on the pile-driving operation (Figures 4 and 5). UHPC was selected as the material to fill the void around the piles due to its self-consolidating, permeability, and shrinkage-compensating properties to ensure full contact between the precast abutment and the steel piles.