Weatherproofing ICF Walls: Lessons in resiliency from B.C. field testing

Module 1: Recessed (internal) wood buckout

This sample used a recessed wood buckout left in place after pouring of concrete—a method commonly used in ICF projects across North America. The installation was completed with a box-framed window, which was mounted at the outside edge of the concrete core via clips fastened to the wood buck. A reglet was cut into the EPS above the window, back to the concrete core. Window flashing mandated by NBC and Part 9 of the B.C. Building Code was applied to all sides of the window in ‘shingled’ fashion, with the head flashing sealed back to concrete inside the top reglet. Both the interior and exterior face of the window were sealed with foam backer-rod and silicone sealant.

The module was successful in resisting air and water infiltration up to pressures of 300 Pa (6.26 psf), which is equivalent to moderate to severe conditions expected on low- to mid-rise construction.

Module 2: EIFS basecoat

The second wall section also used an internal wood buck, but an exterior insulation and finish system (EIFS) basecoat layer was wrapped from the exterior face of the building back into the window opening, past the position of the window. This method is common in commercial and multi-family residential buildings finished with face-sealed EIFS or stucco systems. A box-framed window was also positioned at the exterior face of the concrete core, and again, the interior and exterior faces of the window were sealed with foam backer-rod and silicone sealant.

The module was successful in resisting twice the air and water infiltration of the first sample at 700 Pa (14.62 psf), equivalent to the most severe conditions expected on high-rise construction in any building use category. This module was likely more successful because of the direct connection of the window frame to a fully sealed exterior wall coating wrapped back into the window opening.

Module 3: Hybrid wood buckout with flanged window

The third sample used a flanged window with a wood substrate flush to the exterior face of the ICF wall. This method is common in low-rise residential buildings finished with face-sealed (i.e. stucco) systems or a variety of cladding options (including lapped siding, panelized cladding, vinyl, and shingle applications), and was deemed critical by the ICF stakeholders. In this module, a flanged window was fastened to the outer face of a permanent wood buckout at the exterior face of the EPS. Code-mandated window flashing was also applied to all sides of the window in shingled fashion, with the head flashing sealed back to concrete inside the top reglet. Only the interior face of the window was sealed with foam backer-rod and silicone sealant.

The module was successful in resisting air and water infiltration up to pressures of 300 Pa—the same as the first sample tested in this phase.

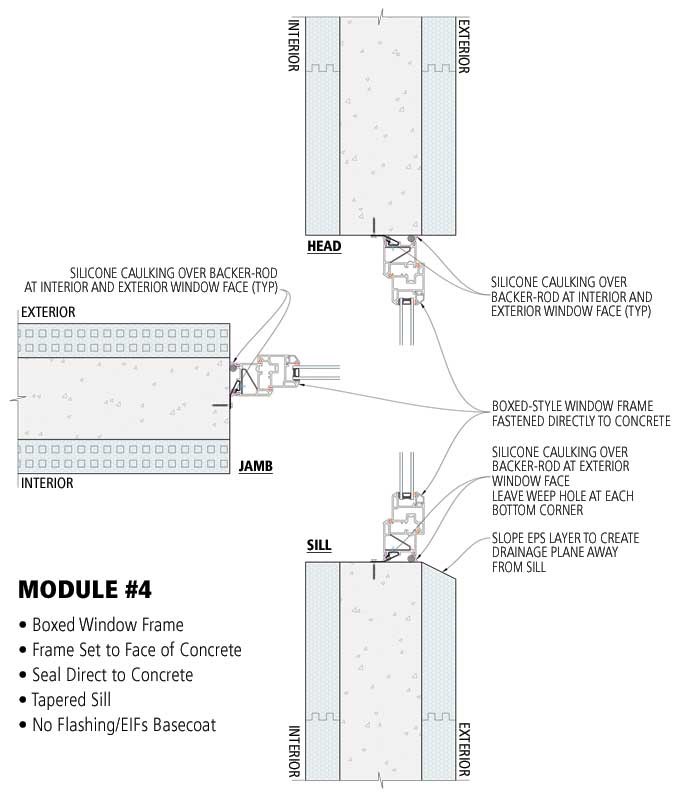

Module 4: Window sealed directly to concrete rough opening

In the fourth sample, the buck was stripped after the pour, leaving the concrete core exposed. This method is common in multi-storey commercial and multi-family buildings of any height. A box-framed window was positioned at the exterior face of the concrete core for this module, and both the interior and exterior faces of the window were sealed directly to the concrete core with foam backer-rod and silicone sealant.

Since the concrete core provides full protection, no exterior window flashing was required.

This assembly was by far the most successful at resisting water and air infiltration—after having resisted pressures up to 5000 Pa (104.42 psf) in laboratory testing, the field-test module was successful in resisting air and water infiltration up to pressures of 700 Pa (14.62 psf).

This extraordinary performance is equivalent to wind-speed conditions of more than 804 km/hr

(500 mph). Such conditions do not naturally exist on this planet, but this ICF wall/window assembly has proven to be fully resistant to them. (The top commonly recognized wind-speed range uses the Enhanced Fujita Scale, [EF] which defines an EF5 tornado as having wind speeds ranging from 419 to 512 km/hr [261 to 318 mph]. For more on the Fujita Scale, visit en.wikipedia.org/wiki/Enhanced_Fujita_scale.) In this author’s opinion, it is a game-changer for the ICF industry.

Not only was this fourth module the most effective at preventing air and water intrusion, but because it needs no added flashings, it also represents the least-expensive option for ICF installers.