Vapour diffusion and condensation control for commercial wall assemblies

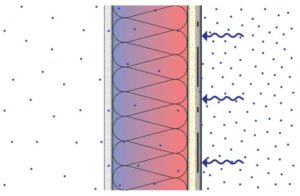

Dewpoint and condensation

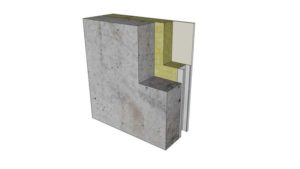

The dewpoint within a wall assembly can be described as the temperature at which the indoor air reaches

100 per cent relative humidity (RH), and usually occurs within the insulation layer of the assembly as it has the greatest temperature gradient. However, the critical layer is the condensing surface, the first cold surface within the assembly. In cold climates, this usually relates to the interior side of the exterior sheathing. The use of continuous exterior insulation reduces the risk of condensation as it will maintain the critical layers warmer and above the dewpoint. With that being said, potential for condensation is mostly critical if the assembly is not designed to dry out.

Air leakage

Air leakage is an even greater concern than vapour diffusion and is a critical factor impacting wall assembly performance and durability. As a result, it must be carefully addressed because it can act quickly to deposit large amounts of water in a wall assembly in a short period of time. Difference in air pressure between the interior and exterior of a building drives air pressure through a wall assembly from the high pressure side to the low pressure side. To control air leakage in building enclosure assemblies, an air barrier is installed. Attention to connections and the use of tapes and sealants are important to ensure a continuous air barrier system. Unlike vapour diffusion, air leakage is not dependent on the material properties of the air barrier, but most often occurs due to holes in the air barrier. When air leakage does occur, it carries moisture. If the air then comes in contact with a surface below the dewpoint temperature of the air, condensation can occur,

leading to potential fungal growth or degradation of the assembly and its components.

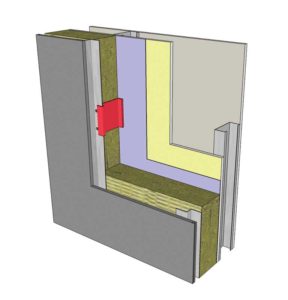

Wrong side and double vapour

Improper installation can also cause moisture problems. Two common conditions causing serious issues are vapour barriers placed on the wrong side and double vapour retarders. A vapour retarder placed incorrectly is one that is situated on the low pressure or cold side of the wall assembly, restricting vapour diffusion and subsequently creating a potential condensing plane in the wall assembly.

Double vapour retarders refer to when a vapour retarder is installed at two locations in a wall assembly, negatively impacting drying potential should water or any moisture get between them. Moisture between vapour retarders may be the result of air leakage, rainwater ingress, or built-in construction moisture.