Using roofing parapets for airtight roofs

Using these tools, the designer can determine what level of uplift resistance they need in a roof assembly and its various zones, and by using this information, they can source proven and tested roofing assemblies offered by roofing manufacturers who participate in a CSA 123.21 testing and verification program.

As wind speeds increase across a low-slope roofing assembly, so do the uplift forces. As expected, a mechanically attached membrane will tend to billow and deform during these wind events where a fully adhered membrane will be more likely to stay in place.

When a membrane billows, it is a result of uplift on the topside overcoming adhesion or other downward forces on the bottom side. So what forces are keeping a membrane down? Ballast or weights in the form of stones or pavers are a popular choice for inverted membranes. A system of insulation, fabric, and ballast that holds a waterproof membrane in place. This can be a good option where additional weight on the structure is not a concern. However, the ballast itself may become a concern as it is subject to potential movement and wind scouring (redistribution of ballast by wind at corners and edges of roofs).

Mechanical fasteners and plates provide a solid connection to the structural deck, but are intermittent and impose point loads and thermal bridges onto the membrane which can wear and weaken the materials over time.

Adhesives, when fully spread onto the field of single ply membranes, or when ribbons are close together, provides an excellent connection to the structure. This method is gaining popularity with not only membranes, but entire assemblies of insulation and cover boards. Its primary benefit is ease of use, reduction of puncture risk (especially in re-roofs) and thermal bridging, and its high bond strength. Many forms of modified-bitumen roofing employ either built-in adhesives (e.g. self-adhesive or torchable adhesives) and spreadable adhesives (e.g. hot or cold asphalts).

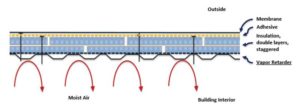

Fully adhered and detailed air and vapour barriers at the structural deck level are another method to ensure the primary water and air barrier (i.e. the membrane) stay in place during wind events. Imagine a membrane wants to billow due to the uplift forces of the wind, but what if there was enough air suction below the membrane to keep it in place? The introduction of and careful detailing of an air barrier at this level ensures there is no air available to enter the assembly to fill the volume under the billowed membrane, effectively acting as suction from below, keeping the primary membrane in place. An easy way to see this is by taking a Ziploc bag, removing all the air, and sealing it tight. Then try to pull the two sides apart—with no air to fill the bag, suction will keep the sides from separating.

Roof parapets and corners

Why do roof parapets and corners seem to get all the attention? In this situation, the saying, “the squeaky wheel gets all the grease” is applicable, as wind acts on buildings, it has to speed up to get up and over the roof. This increase in speed and upward pressure can be far more destructive than the field of the roof.

As air twists and turns around parapets and corners, it creates a variety of forces capable of moving ballast, and working loose membranes free. It also happens at a location where the wall-to-roof air barrier is difficult to detail and subsequently at a higher risk of air leakage.

Air leakage at this critical point of membrane connection can be problematic. It can provide the weak link in the envelope that damaging winds can exploit, resulting in roof blow-offs and other major failures. It can be a point of major infiltration and exfiltration and depending on the temperatures, can become a major source of condensation.