Using brick veneer and metal studs for strong walls

by Katie Daniel | May 25, 2016 10:38 am

By Michael Gurevich

The brick veneer/metal stud (BV/MS) backup exterior wall assembly was invented in New England in the 1970s. This type of system was formed to substitute the more expansive concrete masonry unit (CMU) backup wall because it is installed much more quickly. Now, new innovations have improved the assembly further.

The original design had contained fibreglass insulation within the stud space, and exterior/interior gypsum board sheathing on each side of the studs. The outside face of the stud backup system had #15 felt installed over it to protect the exterior gypsum board sheathing from moisture. Various different masonry ties were developed to anchor the brick veneer to the studs. As the system was new in the 1970s, no real standards were developed for the design of this wall system.

Building code and industry standards

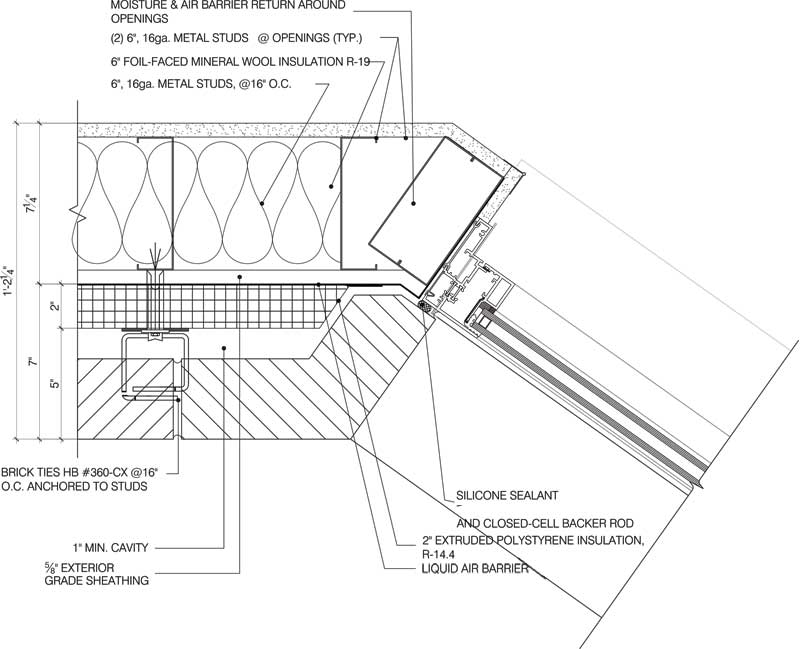

To help compensate for the lack of standards, the Brick Industry Association (BIA) revised its Technical Notes on Brick Construction #28B, Brick Veneer Steel Stud Walls, in February 1987. It recommends the maximum deflection for the steel stud backup, when considered alone at full lateral design load, be L/600 to L/700.The minimum air space had been increased to 51 mm (2 in.), so ties must be spaced closer.

There should be one tie for each 0.18 m2 (2 sf) of wall area. This is because 25-mm (1-in) air spaces could be bridged by mortar drops, and moisture could migrate inside of the building.

In 2008, The Masonry Society (TMS) 402-08/American Concrete Institute (ACI) 530-08/American Society of Civil Engineers (ASCE) 5-08, Building Code Requirements and Specification for Masonry Structures and Related Commentaries, issued a new chapter, ‘Anchored Veneer,’ with requirements for brick veneer with metal stud backup exterior wall systems. The chapter stated:

If anchored veneer with a backing of cold-formed steel framing exceeds the height of 9.1 m (30 ft) above the noncombustible foundation, the weight of the veneer shall be supported by noncombustible construction for each storey above the height limit of 9.1 m. Thus, continuous steel shelf angle should be provided at each floor above the limit to support the brick veneer.

Thermal bridging at studs

The exterior walls were originally designed with fibreglass batt insulation located between the metal studs, with no insulation over the exterior face of the studs. This batt insulation had a kraft paper or foil facing the building interior that was intended to act as a vapour barrier in colder climates. During the winter in these regions, the exterior flange of the stud was exposed to the cold air behind the brick veneer. The interior flange of the same stud was exposed to the interior warm air, which caused thermal bridging at the metal stud. Thus, condensation could form at the cold surface of the exterior flange. This moisture could potentially contribute to mildew development inside the wall system.

One of the weak points in the BV/MS exterior wall system is the masonry ties, which should anchor the brick veneer to the metal studs. All masonry ties should be connected to the steel studs with screws. Approximately two threads of the screw hold it in the 16-gage outside flange of the metal stud. Thermal bridging can cause condensation moisture at the cold, inside face of this outside flange of the stud. Therefore, rust or a galvanic cell reaction could develop at the juncture between the screw and the stud.

After a few years, this means the connection between the screw and the stud could deteriorate and become loose, allowing the masonry tie and brick veneer to follow suit. Ultimately, this leads to movement and cracks in the horizontal (bed) joints of the brick veneer. Cracks can then lead to water penetration through the brick veneer, which could provide an avenue for moisture to get inside the building.

Insulation moving to exterior side of the wall

The 2000 International Building Code (IBC), specifically the ‘Energy Conservation’ section, included provisions to help eliminate thermal bridging at metal stud locations. The new provision has a minimum design requirement of exterior sheathing on the outside face of the metal studs with rigid insulation containing an R-value of at least R-3.

Consequently, 19 mm (3⁄4 in.) of extruded polystyrene (XPS) insulation board with an R-value of R-3.75 should be installed on the outside face of the metal studs, eliminating thermal bridging at this area. This could also avoid the possibility of screw-to-metal-stud connection deterioration. Good thermal performance means having the entire insulation located at the outside face of the studs. No batt insulation would be required.

At the beginning of the 21st century, new industry standards to locate the 51 mm (2 in.) of XPS insulation board (R-10) on the outside face of the studs were developed. In this case, the vapour barrier would be located between the exterior paperless gypsum board sheathing and the insulation board, and the vapour barrier would act as an air barrier and a moisture barrier at the same place. It is ideal to specify the 1-mm (40-mil) peel-and-stick membrane, which should be sandwiched between the exterior gypsum board sheathing and the insulation board. This exterior wall system works well for cold and hot climates. Condensation analysis should help verify the proper location of the vapour barrier in the wall system.

Image courtesy Centria

At the construction site

During this author’s various inspections of the exterior wall installations, the drywall or masonry contractor installed the insulation board. Unfortunately, sloppy installation of the XPS insulation boards occurred in many of these cases. As a result, the R-value suffered.

Contractors often cut insulation board using a hand-saw, which sometimes leaves gaps up to 19 mm (¾ in.) between the uneven edges of the boards. Some of the boards had 135-degree corners, which was a problem if it met up with other boards with 90-degree, square corners. When the boards met in this fashion, a triangular-shaped gap in the continuous insulation was left. In another instance, at narrow window or door jambs of 102 mm (4 in.) with double or triple studs, the insulation was sometimes not installed at all (Figure 1).

When a designer calls for a liquid air barrier to be installed over the exterior gypsum board sheathing (that is, behind the 51-mm [2-in.] XPS insulation board) the elastomeric coat has low permeability, and will also act as a vapour barrier. When foil-faced mineral wool insulation with R-19 is to be installed within the metal studs, the foil located at the inside face of the wall will act as the second vapour barrier. The dewpoint in this wall system will be located between two vapour barriers, which should be verified by condensation analysis for both summer and winter conditions. Only one vapour barrier should be installed at the winter warm side of this wall (for the northern climate zones).

In many cases, the insulation board was cut out to install the masonry ties. However, after the ties were installed, these spots were left with a 51-mm (2-in.) square opening.

All these insulation deficiencies would jeopardize the continuous R-value of the wall system. Far too frequently, insulation boards are installed with insufficiently tight joints. To achieve these tight joints, contractors should cut XPS insulation boards with a table circular saw.

Insulated composite backup panels

Innovations for the BV/MS backup exterior wall can be derived from the insulated composite backup panel (ICBP) system. The ICBP has panels with two face shells made out of galvanized steel with the polyisocyanurate (polyiso) insulation between. Panels are available with a 51 mm (2 in.) thickness with R-14, and a 76 mm (3 in.) thickness with R-21. Panels are 813 mm (32 in.) wide with tongue and groove longitudinal (horizontal) joints, which has factory installed gaskets. Thus, when one panel is installed over another, the longitudinal joints between the panels automatically seals, ensuring a foolproof installation.

Generally, panels are 3.7 m (12 ft) long, although 6-m (20-ft) panels are available. In these products, only one joint between the panel end and the steel stud should be sealed at the construction site with a butyl sealant. L-shaped masonry ties should be installed into the horizontal joints between 812-mm (32-in.) wide panels. The tie vertical leg is installed over the tongue part of the panel and attached to the stud with the screw, which attaches the panel to the steel stud. Masonry ties should be installed at 406 mm (16 in.) on center (oc) vertically, and additional L-shaped masonry ties, with shorter horizontal legs, should be installed in the middle of the panel width with tape to seal the screw penetration through the panel.

As an exterior wall metal panel, ICBPs are installed as a backup with BV/MS, but lack an esthetic finish. Since the face of the ICBP system with sealed seams is not sensitive to any moisture, the air space between the brick veneer and the ICBP could be reduced to 25 mm (1 in.). Also, the ICBP system is suitable for rainscreen wall system design.

Single-step installation of an ICBP system could substitute the three steps of installation of exterior gypsum board sheathing, vapour/air barriers, and insulation board with considerable labour savings. During a large-scale project, four to six weeks could be cut from the construction schedule with a substantial cost savings to the owner.

One of the first large-scale projects with an ICBP system was built south of Boston. The four-storey, 20,438-m2 (220,000-sf) office building’s exterior walls were enclosed by the panels in the winter within 10 working days. BV/MS would take three times as long because the contractor needs scaffolding to install it. The brick veneer was installed with warmer weather in April.

Specifying the insulated composite backup panel system simplifies the backup wall installation of brick veneer/metal stud assembly and eliminates potential problems. The system could be installed in the winter to enclose the building envelope. It provides cost savings for building developers, specifically for large-scale projects.

Michael Gurevich is a masonry consultant at the New York City Brickwork Design Center (NYCBDC), which conducts free seminars on a variety of topics—such as barick veneer metal stud backup exterior walls—for CSI and American Institute of Architects (AIA) chapters. He has 30 years of experience working with exterior masonry walls. Gurevich holds a master’s degree in structural engineering from Belarussian State Polytech University in Minsk. He can be contacted via e-mail at nycbdc@aol.com[1].

Michael Gurevich is a masonry consultant at the New York City Brickwork Design Center (NYCBDC), which conducts free seminars on a variety of topics—such as barick veneer metal stud backup exterior walls—for CSI and American Institute of Architects (AIA) chapters. He has 30 years of experience working with exterior masonry walls. Gurevich holds a master’s degree in structural engineering from Belarussian State Polytech University in Minsk. He can be contacted via e-mail at nycbdc@aol.com[1].

- nycbdc@aol.com: mailto:nycbdc@aol.com

Source URL: https://www.constructioncanada.net/using-brick-veneer-and-metal-studs-for-strong-walls/