Understanding the acoustical challenges of mass timber buildings

Photo courtesy McKinstry

Acoustical challenges

The most attractive aspects of mass timber—lightness and structural characteristics—is actually its greatest downfall in terms of acoustics. The structural material is lighter than concrete, making it harder to stop the transmission of sound. Therefore, low-frequency sounds transfer easier through walls in a wood-framed building than a concrete one. With acoustics, more mass like concrete typically means better noise control. This includes impact noises from footfalls or running children, or from airborne sound from a stereo system or loud voices.

Sound transmission class (STC) rating is the ability of a material to reduce transmission of sound between rooms. Generally, the higher the STC number, the less sound is transmitted. Typically, an STC rating of 50 is desirable, and also required by code between residential spaces. However, a single number does not tell the whole story.

It is important to note the sound transmission requirements, acoustical challenges, and potential solutions will slightly differ between residential and commercial buildings. In commercial buildings, it is not uncommon for the landlord to request an exposed ceiling to showcase the mass timber construction. The irony is this is similar to the office spaces of the early 19th century when buildings were built with layers of 2x4s. Today, the modern wood-look, combined with the ability to showcase a building’s low-environmental impact, may allow the landlord to charge a premium for the space. While it looks great esthetically, it poses major issues around sound transmission. There are no requirements or building code recommendations on sound transmission in commercial spaces, but some tenants might require a quieter space, so landlords need to consider this in the design process.

Most building codes mandate a specific sound performance or STC rating for walls and floor systems in residential spaces. However, high STC ratings alone will not guarantee ideal soundproofing as sound not only travels through the air from one room to another, but also via indirect paths such as ducts, duct walls, floors, ceilings, or even gaps and cracks. Known as flanking noise, this type of sound transfer is unaccounted for in STC ratings determined in laboratories.

Flanking paths can be a critical issue in mass timber construction, and without proper acoustical planning, result in a lot of complaints from residents. Mass timber spectral characteristics are less desirable in comparison to traditional concrete or concrete/steel assemblies for certain types of sound. Due to the heavier assembly, concrete has a significant advantage when it comes to minimizing the transmission of low-frequency sounds, such as those from small home theatres, banging noises, mechanical equipment, and noisy neighbours.

In comparison to a concrete STC 50 partition, with a mass timber assembly—built-up with additional layers to achieve the same rating—it can easily be twice as loud (5 dB worse) in low-frequency sound areas. Relying on a single STC 50 for code reasons will not result in performance similar to concrete condominiums in 95 per cent of the buildings out there. With that said, for other types of sounds such as normal voices, general living room/kitchen activities, the addition of concrete on top of an air space filled with a soft material such as insulation or a rubber matt, can provide significant benefits.

It is very critical to consider apparent sound transmission class (ASTC), a more realistic measure of the actual sound level transmitted between occupants since it includes noise transmitted through wall, ceiling, and floor junctions, as opposed to STC, which is a laboratory test made under controlled conditions and construction requirements. The updated building code is expected to require the calculation of ASTC in all permit submissions and this will have a significant impact on mass timber buildings. This building code change should produce better performing buildings and is a great thing for the industry, but like anything that increases performance, the cost associated with engineering and construction will also rise. In addition to an STC rating of 50 for walls, all residential assemblies and their short-circuit paths will have to show, on paper, they can achieve an STC rating of 47 or higher. This means the details of connection points, holes, how things get tied together, and construction sequencing becomes far more important than ever with mass timber construction. Previous to this, for typical construction, ASTC tests indicate most assemblies typically test within approximately 5 dB of the lab-rated STC value (Figure 1).

This does not mean wood buildings will be noisy. With proper acoustical design, residents can have similar privacy in wood structures as they have come to expect from steel and concrete buildings. However, like many engineering trade-offs, this does not come without additional cost and implications on services, floor-to-floor heights, and performance. There are several ways to minimize sound transfer in mass timber buildings.

Determine the right mass timber option

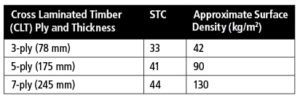

There are various options when it comes to mass timber, such as CLT, NLT, mass plywood panel (MPP), as well as dowel-laminated timber (DLT). Controlled laboratory STC testing, where the sound transmission of a material is accurately measured between rooms, has found CLT performs slightly better as the laminates are cross-oriented in a panel, have less susceptibility for small holes and cracks, and is generally more monolithic than DLT and NLT.