Understanding Canada’s VOC regulations

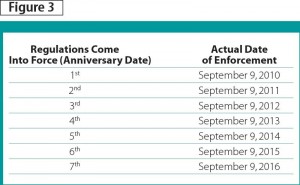

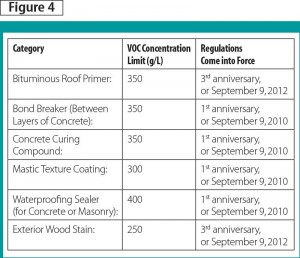

Figure 3 is a complete listing of the anniversary dates with the corresponding enforcement dates. Taking the same product categories used earlier, Figure 4 shows the actual dates when products in those categories must meet the respective VOC requirement.

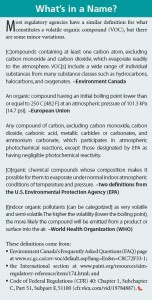

VOC calculation/excluded compounds

VOCs must be calculated using U.S. EPA Method 24, Determination of Volatile Matter Content, not counting the volume of any water and excluded (i.e. exempt) compounds. VOC-excluded compounds are those with fewer tendencies to react photochemically in the atmosphere. For this reason, they are not included as VOC-contributing in a coating formulation/product. While CEPA currently lists numerous compounds as being VOC-excluded, the three most common—found in paint and coating formulations—are acetone, parachlorobenzotrifluoride (PCBTF), and tert-butyl acetate (TBAc).

Products that have been re-formulated with VOC-excluded compounds can have very different physical and performance properties than products made with the typical, VOC-contributing solvents. Reformulated, lower VOC products can also be much more difficult to apply, and have different handling properties due to extremely fast evaporation rates. At times, new application equipment (e.g. sprayers, nozzles, and tips) must be used to achieve proper appearance and performance of new, reformulated, VOC-compliant products.

Lower VOC products, using these exempt compounds, also have a much lower flash point; this means they are classified as ‘flammable.’ This classification forces such products to be increasingly regulated, more hazardous, and more expensive to ship.

Alternative compliance

Instead of meeting the current VOC requirements, manufacturers and importers can request a permit from Environment Canada to allow a product to be made or sold when there is evidence it is not technically or economically feasible at the time of the permit application to reduce the VOC to acceptable levels. The permit applicant must present a plan to the Minister of the Environment that identifies steps that will be taken to ultimately meet the VOC requirement.

The time allowed for compliance cannot exceed four years from the initial issue date of the permit. Further, Environment Canada can deny a permit if there are doubts as to whether the information provided is true and factual, and if insufficient information is provided with the permit application.

Stop manufacture/import and sell-through

Stop manufacture/import and sell-through

The Canadian Architectural Coatings VOC Regulation includes a general sell-through period for most product categories, which ends later this year on September 9. By definition, the majority of products needed to be manufactured and physically present in Canada by this date and can be sold through this point. The exceptions include:

- interior wiping stains;

- exterior wood stains (clear or semitransparent);

- form release compounds; and

- floor enamels,

These products have an extended sell-through date of September 9, 2014.

Sell-through dates are typically added to regulations to provide manufacturers and users time to ‘use up’ products not meeting the VOC requirement. These extended dates can also give manufacturers additional time to reformulate VOC-compliant products, as needed. In conjunction with industry, regulators had determined that without sell-through date provisions to the regulation, both manufacturers and end-users might face disposal of a significant volume of coatings no longer in compliance.

Most-restrictive limit

The regulation also states if a product meets the definition of more than one category, or can be used for more than one type of application, then the most-restrictive requirement will apply. Again, it is extremely critical both manufacturers and end-users determine the proper category for VOC compliance.

The ‘most-restrictive’ provision of the regulation does not apply to the following coating categories:

- antenna coatings;

- bituminous roof primers;

- calcimine re-coaters;

- conjugated oil varnishes;

- fire-retardant coatings;

- flow coatings;

- high-temperature coatings (not currently listed in regulation);

- impacted immersion coatings;

- industrial maintenance coatings (ones that are not currently listed in the regulation);

- lacquers (not currently listed in the regulation), including lacquer sanding sealers;

- low-solids coatings;

- metallic pigment coatings;

- nuclear coatings;

- pre-treatment wash primers;

- shellacs;

- specialty primers, sealers, and undercoaters;

- temperature-indicator safety coatings; and

- thermoplastic rubber coatings and mastics.

Dilution, multiple components, and labelling

If products are to be diluted before use, then specific instructions need to be included on the container label, or must accompany the product in the form of a technical data sheet. The VOC reported for the product is to be listed as “as-used” or “after-dilution.” The same requirement applies to multiple-component products—the proper VOC level reported is for the ‘mixed’ product, rather than individual components.

Additional provisions of the regulation include labeling requirements. The date the coating was manufactured (or a representative code) must be included on the product container or label. For products needing dilution with solvents other than water, instructions need to be present. For those that do not need dilution, a statement the product is to be applied without thinning must be stated on the container’s label or lid. (These examples are a short overview of labelling/container requirements. One should refer to the official regulation for a complete listing of labeling/container needs.)

and sealed walkway, in the Southern United States, was specifically designed to withstand heavy pedestrian traffic.

Exempted products

While the regulation currently governs several specific categories of architectural coating products manufactured, imported, or sold in Canada, there are some exceptions. They include:

- products for application to a product (or component), in or on the premises of a factory or a shop, as part of manufacturing, processing, or repair;

- products to be used in scientific research;

- products to be used as a laboratory sample or analytical standard;

- products for export or for shipment to other persons for processing or repackaging;

- adhesives;

- aerosol coatings (i.e. pressurized coatings containing pigments or resins whose ingredients are dispensed by means of a propellant and are packaged in a disposable can for either hand-held application or by specialized equipment for the marking of streets, highways, or other traffic surfaces);

- antifouling coatings; and

- wood preservatives.

Small containers

The architectural coatings VOC regulation also offers an exemption for certain products when the container size is 1 L (0.2 gal) or less. They include:

- faux finishes;

- any other high-temperature coating;

- any other lacquer, including lacquer sanding sealers;

- any other varnish;

- low-solids coating;

- quick-dry enamel;

- interior wiping stain;

- exterior wood stain;

- any other stain; and

- rust-preventive coating.

Enforcement and challenges ahead

Enforcement and challenges ahead

The same enforcement officers ensuring compliance with CEPA are ultimately responsible for enforcement of the Canadian Architectural Coatings VOC Regulation. Officers will determine the appropriate enforcement action, depending on the nature of the violation. These can range from warnings and environmental protection compliance orders to ticketing, injunctions, and prosecution. ( For more information, visit www.gazette.gc.ca/rp-pr/p2/2009/2009-09-30/html/sor-dors264-eng.html).

Although Canada’s VOC regulation was initially implemented in September 2009, there are still several challenges manufacturers and end-users will face as they attempt to comply with all facets of the regulation. Full knowledge of the regulation as it relates to specific product categories is critical not only for manufacturers and importers, but also design/construction professionals specifying or using architectural coating products.

Dianne Carey, CSI, CDT, is the director of technical services for W.R. Meadows, a manufacturer of concrete construction liquids, waterproofing products, air and vapour barriers, and cementitious repair/restoration products. A chemist, she researches and develops concrete curing compounds, sealers, and penetrating water repellants. Carey is an active member of the American Concrete Institute (ACI), ASTM International, Construction Specifications Institute (CSI), and the U.S. Green Building Council (USGBC). She can be contacted at dcarey@wrmeadows.com.