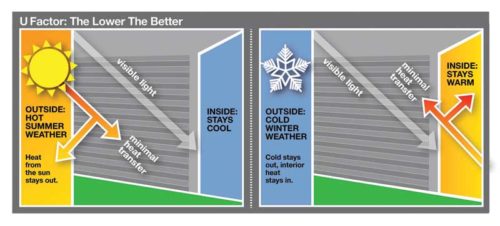

U-factor ratings: A measure of thermal performance

By Heather Bender

Builders in Canada face challenging climate conditions, which makes accurate thermal performance data key in choosing products for their designs. For manufacturers of commercial roll-up and sectional doors, these ratings have traditionally been presented in RSI-value, which is a measure of a component’s thermal resistance. This single measure, however, is proving inadequate for assessing the complex nature of these dynamic, multi-component assemblies.

With the construction industry focused on energy efficiency, sustainability, and green building practices, some roll-up door manufacturers are demonstrating the energy efficiency of their products by putting their doors through U-factor testing to provide a more complete picture of thermal performance. A U-factor rating differs from an RSI-value rating since it represents thermal transfer instead of thermal resistance.

U-factor also differs from U-value, though the two are often confused. Both are measures of thermal transfer rate, but U-factor accounts for the entire door assembly, including all components and how they interact, U-value only measures the thermal transfer rate of a single material or component. This distinction makes U-factor a more accurate and comprehensive measure for selecting rolling and sectional doors that align with Canada’s rigorous energy performance standards.

For architects, engineers, project managers, and specifiers, incorporating these popular door styles into their designs is easier when door manufacturers provide the U-factor rating. This rating helps to more accurately calculate a door’s impact on heating and cooling loads and the overall efficiency of the building envelope.

U-factor, RSI-value, and U-value

Evaluating the thermal performance of a roll-up door using a U-factor rating represents a significant shift in how manufacturers gauge the energy efficiency of their products and how architects specify them.

Traditionally, architects would reference RSI-value and occasionally U-value (if provided by the manufacturer) as the primary indicators of thermal performance because these were the only insulating measures made available. RSI-value (expressed as m2*K/W—or referred to as R-value and expressed as ft2*h*degF/BTU in imperial units) measures the heat resistance of a single material or static component such as a door slat, indicating how well it resists heat flow. With RSI-value ratings, a higher number is desirable, as it indicates stronger resistance.

U-value (expressed as W/m2*K, or BTU/ft2*h*degF in imperial units) is also a rating used for a single material or component, and it captures the rate at which heat is transferred from one side of the component to the other. With U-value ratings, a lower number is desirable.

While RSI-value measures thermal resistance and U-value measures thermal transfer, each measure is limited to capturing the thermal performance of only one material or component of a door—neither measure accounts for the complete door assembly. Comparatively, U-factor, also expressed as

W/m2*K or BTU/ft2*h*degF, represents the rate of thermal transfer through the entire door assembly and includes all the materials and components in the assembly and their arrangement. Like U-value, U-factor measures thermal transfer, so a lower number represents greater efficiency. Unlike U-value, U-factor accounts for the entire door assembly and not just one component. To summarize:

- RSI-value measures the thermal resistance of a single door material or component.

- U-value measures the thermal transfer rate of a single door material or component.

- U-factor measures the thermal transfer rate of the entire door assembly.

By recognizing the difference among these three measures and the information each provides, building professionals can make more informed decisions about the energy efficiency and thermal performance of the doors they select.

Why roll-up door manufacturers are recognizing U-factor

U-factor ratings allow manufacturers to provide architects and specification writers with a much more comprehensive measure of thermal performance than RSI-value alone. The additional testing required for U-factor means the manufacturer’s products may also meet additional industry standards for efficiency. These standards can include U-factor ratings plus other measures such as air infiltration, giving building professionals more metrics to assess and compare these complex architectural elements. Examples of standards which may be cited by a roll-up door manufacturer include:

The standard, DASMA-105, Test Method for Thermal Transmittance and Air Infiltration of Garage Doors, published by the Door & Access Systems Manufacturers International (DASMA) is a defined method for measuring both thermal transfer (U-factor) and air infiltration of a roll-up door assembly. Per DASMA:

Thermal transmittance (U): The time rate of heat flow per unit area under steady state conditions from the air on the warm side of a body to the air on the cold side, per unit temperature difference between the warm and cold air. It is calculated as follows:

U = Q/A(Th – Tc)

U is referred to as the overall coefficient of heat transfer and is commonly known as U-factor.

U = thermal transmittance Btu / hr sqft °F

Q = time rate of heat flow through area A, Btu / hr

A = area of test frame opening normal to heat

flow, sqft

Th = temperature of warm side air, °F

Tc = temperature of cold side air, °F

This standard includes air infiltration as follows:

Air infiltration tests shall be performed on the specimen in accordance with ASTM E-283 at a differential pressure of 1.57 psf (representative of a 25 mph or 11.176 mps wind). This test may be performed within the hot box apparatus or using a separate air infiltration measuring device.1

The DASMA standard acknowledges size and material composition affect thermal performance, and the procedure involves setting specific conditions in a cold room and a warm room to simulate realistic environmental conditions. This standard is critical for architects, project managers, and specification writers, as it helps ensure roll-up doors meet energy efficiency standards and reduce HVAC demand. It also gives decision makers a metric for comparing door models and manufacturers.

As noted within the DASMA-105 standard, the ASTM E-283, Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Skylights, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen, measures air leakage under specific pressure differences to ensure the door meets efficiency standards. Air leakage testing for roll-up doors is an important metric for architects, project managers, and specifiers when selecting products that contribute positively to a building’s energy performance and adhere to regulations. It is also a useful measure for ensuring a comfortable indoor environment for building occupants.2

Not all roll-up door manufacturers include U-factor ratings and standards such as DASMA-105 and ASTM E-283 in their product specifications, but those who do make it easier to specify their products and accurately predict their thermal performance.

Component options can further improve thermal performance

Rolling and sectional doors have grown in popularity for commercial applications for a variety of reasons. They offer flexible use of space, provide a source of natural light, and enhance overall esthetics. With form now equally important to function, many roll-up door manufacturers offer a menu of options for the transparent and translucent sections of their doors and for the metal materials and finishes. Choosing these material options wisely can help improve a door’s thermal performance. For example:

- Insulated glass provides notable resistance to heat flow and can help reduce heat loss in colder climates and heat gain in warmer regions.

- Low-E glass minimizes infrared and UV light without compromising visible light. This reduces heat gain in summer and heat loss in winter.

- Tempered glass adds both durability and insulating properties, contributing to the door’s overall energy efficiency.

- Acrylic or polycarbonate materials designed with thermal breaks and air gaps can offer better insulating properties.

- Steel options with a thermal break and greater thickness can increase the RSI-value of this single component and lower the U-factor of the entire assembly.

- Object detection systems can provide safety as well as efficiency by helping to ensure the door fully closes and completes the thermal envelope.

Each material used in a roll-up door design has different insulating properties that affect the entire assembly’s U-factor. Manufacturers testing their doors for U-factor ratings are a beneficial resource for decision makers because they make this information readily available, and they can help guide customizations for the most efficient outcomes.

U-factor is important for every stakeholder

As U-factor becomes more widely recognized as a comprehensive measure of thermal performance for roll-up doors, manufacturers are working to educate construction professionals about how they can benefit from this metric.

For architects routinely challenged with designing energy-efficient buildings throughout Canada’s diverse environments, designing with a roll-up door that offers a low U-factor is essential for maintaining indoor temperature control, reducing energy consumption, and meeting Canada’s stringent building codes for energy efficiency.

Likewise, engineers can apply U-factor ratings to calculate the overall energy efficiency of a building and measure the heating and cooling loads that will affect operational costs. Ensuring roll-up doors meet optimal performance standards within the larger building envelope is key to designing sustainable and cost-effective buildings.

Project managers and specification writers also consider U-factor important as it relates to a project’s adherence to energy codes. U-factor can be used to control a project’s overall budget in terms of heating and cooling costs and to ensure the selected roll-up doors comply with regulatory standards.

Advocating for efficiency

For building professionals, RSI-value is a familiar metric used when selecting products and materials, but this metric alone is insufficient for a complex architectural element such as a rolling or sectional door. The move by door manufacturers to include more comprehensive measures such as U-factor is a prime example of how all contributors to the construction process play a part in meeting Canada’s goals for optimal efficiency and sustainability. By seeking out these manufacturers, building professionals can make better product decisions using more accurate data and support more efficient product use across the industry.

Notes

1 Refer to the Door & Access Systems Manufacturers Association International (DASMA) at www.dasma.com/wp-content/uploads/pubs/Standards/DASMA-105-Web.pdf.

2 Refer to ASTM International, Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Skylights, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen, at www.astm.org/e0283_e0283m-19.html.

This insulated door is tested and proven to perform best in exterior openings where maintaining environmental separation on each side of the door is necessary.

The key distinctions between RSI-value and U-factor. RSI-value is ideal for evaluating static, single materials such as walls, whereas U-factor is used for dynamic multi-component assemblies such as doors.

This full perimeter door sealing system is combined with thermally broken guide construction and insulated curtains to minimize air infiltration and thermal transference.

This commercial insulated door sealing system not only significantly reduces air infiltration but also reduces sound transmission.