Designing to reduce a building’s embodied carbon

Sustainability metrics

Images © Stephanie Fargas, Dialog

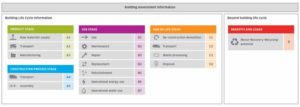

Through its LEED v4 reference standard USGBC has introduced the Building Life-cycle Impact Reduction credit under the Materials and Resources category. The credit’s fourth option allows project teams to conduct a whole building life-cycle assessment (LCA) on the structure to demonstrate a minimum 10 per cent reduction compared to a baseline facility in at least three of the following six impact categories:

- global warming potential (GWP);

- depletion of the stratospheric ozone layer;

- acidification of land and water resources;

- eutrophication (addition of nitrogen or phosphate entering into a water source as run-off causing accelerated aquatic plant growth and depleted oxygen levels);

- formation of tropospheric ozone; and

- depletion of non-renewable energy sources.

It is important to note the GWP category is mandatory. Additionally, no impact category assessed as part of the LCA may increase by more than five per cent compared to the base building.

With LBC, the International Living Future Institute (ILFI) requires projects to account for the total embodied carbon (tCO2e) impact from its construction with a one-time carbon offset from an approved provider, through Imperative 11 – Embodied Carbon Footprint. To comply, the project team is to incorporate carbon-reduction strategies during the design phase, and then purchase certified emissions reductions (CERs), carbon offsets through the institute’s new Living Future Carbon Exchange, or another acceptable third-party verified program to nullify 100 per cent of the CO2e.

The Institute for Sustainable Infrastructure’s (ISI’s) Envision program has a credit under Emissions—Credit CR1.1 Reduce Greenhouse Gas Emissions requires at a minimum a life-cycle carbon analysis and assessment to reduce the project’s anticipated net GHG. This credit offers teams various levels of achievement from ‘improved’ to ‘restorative’, with the latter being the highest, resulting in the project being classified as carbon negative (i.e. sequestering more carbon than produced).

From LCA to environmental product declarations (EPDs), there are various sources and methods of documentation for a project team to determine embodied carbon. An LCA serves as a tool for understanding the energy use intensity (EUI) and environmental impacts by considering all aspects of a building from extraction of raw materials used for construction, manufacturing and installing products, and decommissioning of the building, similar to the cradle-to-grave approach. The European standard EN 15978:2011, Sustainability of Construction Works – Assessment of Environmental Performance of Buildings, is used for whole building LCA. It identifies the calculation method and reporting requirements. In EN 15978, LCAs are conducted to determine the environmental impact of a product or building based on the six impact categories (Figure 1).

Environmental product declarations

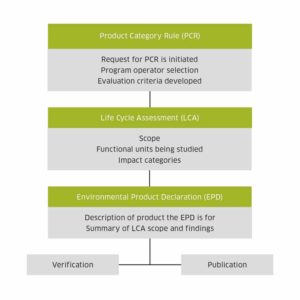

EPDs with the supporting product category rule (PCR) and LCA contain information that can be utilized to determine whether a product can be incorporated into the project to reduce embodied carbon and its contribution toward the environmental impact categories. Before an EPD can be created a PCR is developed to define scope, impact categories, and measurement methods. PCR can be created through assistance and guidance from industry leaders such as associations, governments, and reference standard committees. PCRs are meant to be objective, defining documents serving as the framework for conducting LCAs. PCRs help promote fairness by ensuring all the similar products are measured with the same metrics. PCRs are often initiated as a request from a manufacturer wanting to develop a product-specific EPD. This request is sent to a program operator such as:

- ASTM International;

- ICC Evaluation Service (ICC-ES);

- Institute for Environmental Research and Education (IERE);

- NSF International;

- SCS Global Services; and

- Underwriters Laboratories (UL) Environment (Figure 2).

An EPD conforms to the International Organization for Standardization (ISO) 14025: 2006, Environmental labels and declarations – Type III environmental declarations – Principles and procedures, ISO 14040: 2006, Environmental management – Life cycle assessment – Principles and framework, ISO 14044: 2006, Environmental management – Life cycle assessment – Requirements and guidelines, and EN 15804:2012, Sustainability of Construction Works – Environmental Product Declarations – Core Rules For The Product Category Of Construction Products, or ISO 21930: 2017, Sustainability in buildings and civil engineering works – Core rules for environmental product declarations of construction products and services. EPDs are classified into two main categories:

- industry-wide (generic) – type III; or

- product-specific – type III.

Type III means the product has been verified and certified by a third-party program operator. An industry-wide EPD is verified and is generic to a product type (e.g. gypsum board) but is not specific to a manufacturer. For eligibility, manufacturers are to provide representation in the EPD development either directly or through the program operator. A product-specific EPD is verified and is distinct to a manufacturer as it reflects particular aspects of the production process. These EPDs can be used to conduct a whole building LCA. If a project team wants a specific basis-of-design product, a product-specific EPD can be utilized to research a particular manufacturer’s environmental performance.

When a design team chooses to establish low embodied carbon as criteria for a project, it is important to set targets, develop a strategy for achieving the goals, prioritize products and materials that will be assessed to determine their embodied carbon contribution and potential reduction, and conduct a building LCA. Some strategies include but are not limited to:

- identify the project goal for embodied carbon and the scope of LCA (e.g. what components will be included in the LCA);

- determine the LCA tool and life-cycle inventories (LCI) data source to use;

- identify products’ and building components’ ‘hot spots’ (i.e. highest impact potential) that can contribute to reduction in embodied carbon;

- evaluate the different material types, estimated quantity for each, and anticipated service life;

- explore the possibility of reusing the building structure and/or salvaging building materials to reduce embodied carbon;

- assess options for the material of the building structure to optimize design, utilizing renewable resources (carbon sequestering opportunities) for structures such as heavy timber, or incorporate recycled content such as fly ash or CO2 as an additive alternate to Portland cement to optimize the concrete mix design; and

- design buildings for long service life expectancies (e.g. 50 to 100 years).

When conducting an LCA it is important to maintain consistency in the tool being utilized, as LCI sources vary within the tools and the data may not be comparable or classified differently. Similarly, if an EPD will be used, the referenced PCR needs to be the same amongst the EPDs being compared.