Tom Patterson theatre’s unique acoustical considerations

Finding silence in the curves

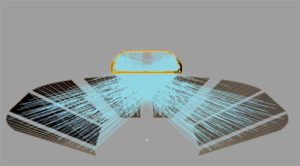

The auditorium is unique because it is acoustically separate from the rest of the building. It is not precisely a box within a box, but rather a hybrid with elements of a separate structure and layering to create a floating shell around the space. The large concave shell over the entire theatre was part of the initial design vision. Traditional acoustic design in theatres avoids concave surfaces, as their effects are not easily analyzed with confidence. There is also the risk of focusing sound unevenly in the room and creating acoustic hotspots that make for suboptimal acoustics. To preserve the esthetic vision while delivering superb acoustics, refined in-house modelling techniques were used to design the acoustics to keep the concave curvature throughout the space. Non-uniform rational basis spline (NURBS) based acoustic analysis tools were used to identify the curve areas that had the potential for focusing, and either change the curvature, or design those areas to be acoustically absorptive. This way, the vision of a large concave shell still meant excellent acoustics. Acoustic bearings were used for structural beams and columns and the inner lining of the auditorium was isolated from concrete by creating a floating liner inside for the finishes.

Usually, there is a base level of quiet in a performance hall. It is akin to how white a canvas an artist needs for a painting. However, the quieter a room gets, the more complicated and expensive the engineering demands become. Typically, live theatre rooms have a noise criterion of NC15 or NC20. For a hall like the new Tom Patterson Theatre, an ambient noise level of not louder than a preferred noise criterion (PNC) of 20 to 25 would typically be recommended. PNC is like NC, except it also has requirements in the lower frequency range. However, the quieter the hall becomes, the more acoustically dynamic the space is. After conducting several demonstrations of different levels of ambient noise, a goal of NC10 was determined as a reasonable target to avoid hearing the noise from mechanical equipment without introducing large amounts of added complexity into the design.

To control the noise, the HVAC system was designed to have a very low supply air speed, and ductwork was fitted with appropriate silencing and acoustic liners. To create a seamless acoustic and esthetic effect, the terminals of the supply ducts were fitted with custom-designed open diffusers that fit naturally into the slatted wood wall/ceiling design. Care had to be taken to ensure the slats did not create aerodynamic turbulence noise as the air exited the ducts into the space.

All the materials in the theatre were carefully selected for their acoustic properties. The right amount and pattern of acoustic reflections is critical in creating a space that works acoustically. For example, the wall and ceiling arcs are unique. The theatre’s side walls have a cohesive walnut wood slat panel curving from the side all the way up to the curved ceiling and are designed to look like a seamless wall or ceiling. This wood slat design is used in two different ways.

Parts of the wall behind the custom seating are acoustically absorptive. The area above the audience plane has a different backing material, making it reflective to optimize the overall acoustics, and to deal with curvatures that could have been problematic. This provides a seamless look and offers absorption and reflection where needed. The theatre’s double-layered masonry construction not only ensured the acoustical warmth of the venue is preserved, but also controlled sound from the outside.

The design incorporates a carefully configured roof construction to prevent external sources of noise from penetrating the facility and to mitigate rainfall noise on the roof above the auditorium. To create a greater separation between the stage house and loading area, heavy doors with a sound transmission class (STC) rating of 50 were specified.