Three common continuous mineral fibre myths debunked

Myth #2: Water absorption reduces mineral fibre’s effectiveness

Typically, moisture is the main cause of building failures. Therefore, designers and architects have many concerns to address when designing their enclosures for durability and performance. There is an unsubstantiated perception in the industry that fibrous continuous insulation absorbs water and takes many hours to dry out, but this is not the case.

As it does with wind, the façade or rainscreen effectively blocks approximately 90 to 95 per cent of rain as it falls on the building. The remaining five to 10 per cent tends to drain out the back side of the cladding, but a small amount may fall on the face of the insulation. The s water hitting the face of the insulation repels off the product, as the fibres are treated with water-repellent oil. Moreover, the non-directional fibres create small voids in the insulation board, which minimize the wicking of water into the product, similar to water draining though crushed stone at the foundation wall. Gravity also helps propel water down and to a location where it can be directed outside of the enclosure. This is even the case with open-jointed rainscreen systems.

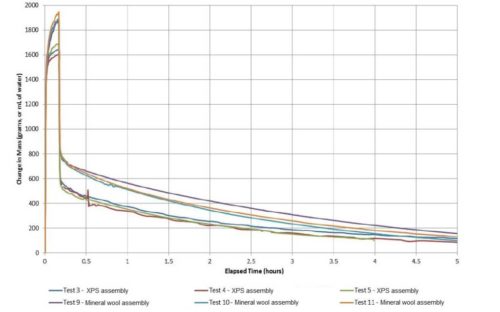

The image below shows an open-jointed rainscreen with the water absorption of extruded polystyrene (XPS) board insulation compared to mineral fibre board insulation, as well as the elapsed drying period. As shown in the chart, the difference between the two is minimal. The perception of water absorption in mineral fibre was derived from submerging mineral wool in water for two hours, then weighing it and seeing how long it takes to dry. If a wall enclosure sees this amount of bulk water in two hours, mineral fibre is the least of the design team’s worries.

Photo © Jonathan Smegal. Photo courtesy Building Science Laboratories | Building Science Consulting Inc.

Myth #3: Mineral fibre loses R-value at cold temperatures

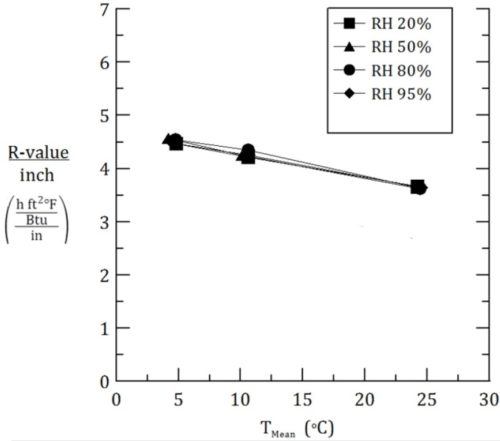

Photo © Ivan Beentjes and John L. Wright, University of Waterloo

Since fibrous insulation does not use blowing agents in the manufacturing process, there is no potential for R-value loss due to temperature. R-value of fibrous insulation actually increases when the temperature decreases, due to the radiation function of heat transfer, which dramatically drops with the temperature (as shown at right). Third-party testing of fibrous insulation supports this as well. This is similar to most other insulations, although certain products, such as polyisocyanurate (polyiso), see a decrease at low temperatures. The reason for the decreased R-value in these insulation products is the fact the blowing agents in the products condense in the cells, which increases the thermal conductivity of the insulation. This does not happen in fibrous insulation products, as the R-value is obtained from trapping still air.

Conclusion

For the most part, there is no such thing as bad insulation—just bad application. Using a higher-density fibrous insulation as a continuous layer is a very good application, and there should be no concerns regarding wind-washing, water absorption, or loss of R-value. It is important to understand fibrous insulation is only a component within a system, so a complete understanding of the enclosure and its performance should always be achieved.

Antoine Habellion, M.Eng., M.A.S., is a building science project manager at ROXUL Inc., where the majority of his work entails managing research projects related to energy efficiency, enclosure performance, summer comfort, hygrothermal analysis, building information modelling (BIM), durability, and resilience. He holds master’s degrees in civil engineering (from Hautes Etudes d’Ingénieur in Lille, France) and green building design (from Arts et Métiers ParisTech in Paris). Habellion can be reached via e-mail at antoine.habellion@roxul.com.

Antoine Habellion, M.Eng., M.A.S., is a building science project manager at ROXUL Inc., where the majority of his work entails managing research projects related to energy efficiency, enclosure performance, summer comfort, hygrothermal analysis, building information modelling (BIM), durability, and resilience. He holds master’s degrees in civil engineering (from Hautes Etudes d’Ingénieur in Lille, France) and green building design (from Arts et Métiers ParisTech in Paris). Habellion can be reached via e-mail at antoine.habellion@roxul.com.