Thermal bridging at brick ties

By Michael Wilson, M.Eng., P.Eng., FEC, and Graham Finch, MASc, P.Eng.

Insulation placed in the exterior air cavity between brick veneer and a backup wall is now common practice; however, accounting for the reduction in thermal performance as a result of thermal bridging at brick ties is not. As the building enclosure’s actual thermal performance becomes more important and integrated into the overall design of other building systems, a clear understanding of thermal bridging and its impact on effective R-values is needed. Brick ties are only one example of a thermal bridge in the building enclosure, but a close look at their significance illustrates how important it is to account for thermal bridging.

Effective R-value and energy codes

Compliance with energy codes in Canada is becoming a design and construction requirement with increasing demands. National, provincial, and municipal building codes have referenced either American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) 90.1, Energy Standard for Buildings Except Low-rise Residential Buildings, or the National Energy Code for Buildings (NECB) for building’s energy efficiency requirements. Both of these energy standards have been recently updated—2011 NECB and 2010 ASHRAE 90.1—and more stringent thermal requirements for walls (i.e. minimum effective R-values) have been adopted.

![This table shows minimum effective R-value requirements for building enclosure assemblies within 2011 National Energy Code for Buildings (NECB) and ASHRAE 90.1-2010, Energy Standard for Buildings Except Low-rise Residential Buildings. [CREDIT] Table courtesy Michael Wilson and Graham Finch, map courtesy ASHRAE](https://www.constructioncanada.net/wp-content/uploads/2014/05/CC_April_14_HR-50.jpg)

Energy codes currently provide for simplified methods to reduce the burden on designers to account for thermal bridging. The use of effective R-values with an account of thermal bridging is becoming more common because 2D and 3D finite element heat flow calculation software is readily available and used by practitioners to calculate effective R-values. (Common programs include THERM for two-dimensional building heat-transfer modelling and HEAT3 for transient and steady-state heat transfer modelling.)

One simplification many designers interpret as permitted by some energy codes is to ignore the area of a thermal bridge if its space occupies less than one per cent—or, in some cases, up to five per cent—of the wall surface area for energy code compliance calculations. The significance of small clips such as brick ties and shelf angles are currently thought to be small and ignored in some energy code compliance checks. This is likely to change as it is recognized metal cladding support connections occupying less than 0.05 per cent of the walls’ surface area can impact effective R-values anywhere from 10 to more than 50 per cent. Integrated design of related building systems will be challenged if actual enclosure thermal performance cannot be reasonably predicted.

Figure 1 provides a summary of the minimum effective R-values for building enclosure assemblies within NECB and ASHRAE 90.1 Climate Zones.

Figure 1 provides a summary of the minimum effective R-values for building enclosure assemblies within NECB and ASHRAE 90.1 Climate Zones.

Impact of brick tie thermal bridging

The impact of brick tie thermal bridging can be examined by reviewing typical exterior insulation reduction factors and effective R-values for brick veneer with various brick ties and backup walls constructed of concrete, steel-stud, and wood-stud frame. To provide perspective on the magnitude of the impact, it is necessary to review fastening systems’ effect for other common attached cladding systems, such as horizontal and vertical metal girts, and those with intermittent clips.

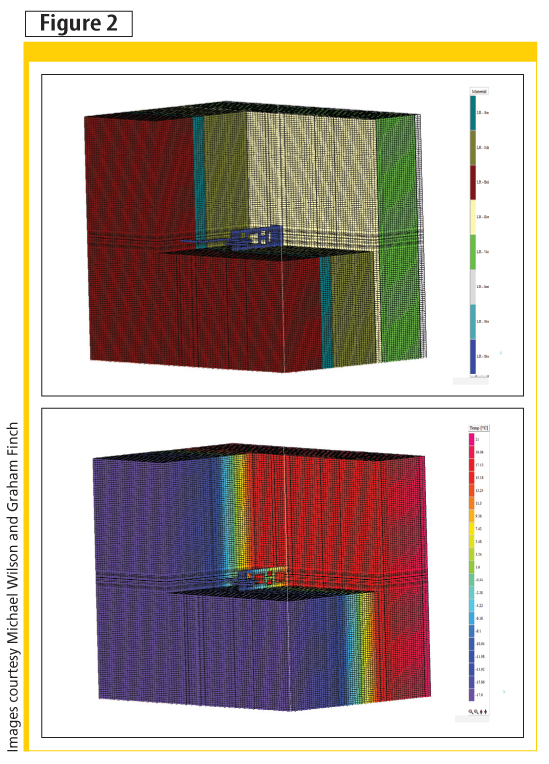

Data presented in this article was obtained from software providing 3D thermal analysis of various brick tie and alternate cladding support systems performed using a software package tested and validated by the building industry and commonly used by practitioners to calculate effective R-values for enclosure.1 The 3D thermal modelling allows for more accurate representation of discrete cladding attachment elements, such as brick ties, than 2D software (Figure 2).2

Three-dimensional models of a brick veneer assembly with typical brick ties attached to concrete, un-insulated 92-mm (3 5/8-in.) steel studs, and R-12 insulated 2×4 wood studs. The generic types of brick ties included in the analysis are:

- galvanized steel 50.8 mm (2 in.) x 16-gauge L-brick ties (with and without punched holes to reduce steel area and conductivity);

- stainless steel 50.8 mm x 16-gauge L-brick ties (with and without punched holes to reduce steel area and conductivity, as in Figure 3); and

- stainless steel 50.8 mm x 16-gauge brick tie side-mounted to stud (for steel and wood stud cases only).

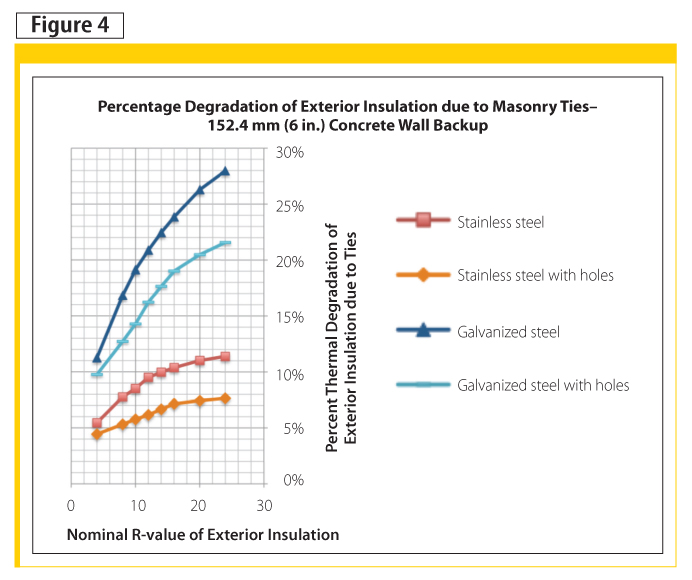

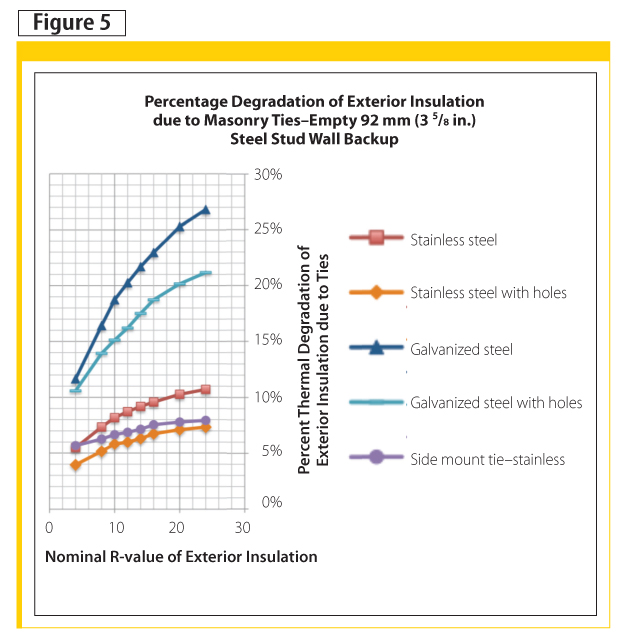

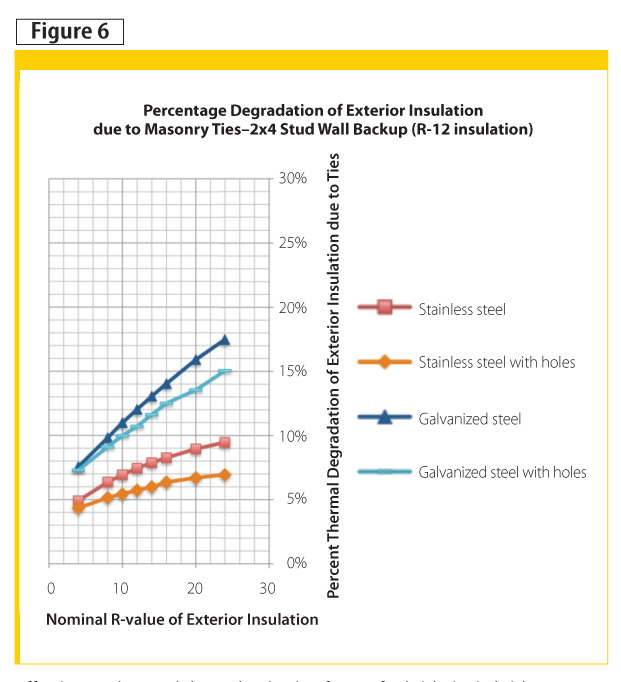

Figures 4, 5, and 6 show the effective R-values and thermal reduction percentage for the aforementioned exterior insulation of different brick ties and backup walls. The effective R-values are for the centre of wall and do not account for thermal bridging at the slab edge condition or brick shelf angle attachment. The surface area of wall being occupied by the brick ties is an almost negligible 0.04 per cent, but the significance of the thermal bridge on effective R-value is certainly not negligible.

The backup wall affects the thermal transfer through the brick ties due to the connections’ contact resistance, with concrete being the worst, followed by steel stud/gypsum, and sheathing/wood studs. (To convert from Imperial (IP) R-values to metric R (RSI) values, chart values can be divided by a conversion factor of 5.678.)

Significance of thermal bridging

The selection of brick tie material and design can have a significant impact on the effective R-value of brick veneer walls. The reduction can be anywhere from five to almost 30 per cent depending on the thickness of exterior insulation and backup wall structure, which can be an important consideration for energy code compliance.

Each of these brick ties occupies about 0.04 per cent of the overall wall area, which means the rules within some energy codes would allow such thermal bridge effects to be ignored in compliance checks for simplification purposes. The results shown in the article demonstrate this code compliance simplification results in overstated R-values (i.e. up to 30 per cent) and should not be applied in energy models relying on integrated design of other building systems or for compliance through enclosure trade-off methods.

When it comes to thermal bridging, stainless steel performs significantly better than galvanized steel, with exterior insulation reductions in the order of five to 12 per cent for stainless steel over concrete/steel backup versus 15 to 28 per cent for galvanized steel. There are cost implications to the selection of stainless steel; however, the additional cost could be offset by the additional insulation thickness that might otherwise be required to meet a certain R-value target with galvanized ties and by the energy savings.

Thermal bridging impacts in other systems

Claddings such as metal panel, fibre cement panels, stucco, thin cultured stone, and thin brick with exterior insulation are supported by fastening systems such as continuous girts, intermittent clips, and screws. These fastening systems penetrate the exterior insulation and are typically larger than brick ties as they resist both lateral and gravity loads.

To compare the impact of thermal bridging at brick ties to fasteners in other cladding systems, it is necessary to also account for the thermal bridging at the gravity support for the brick veneer.“Masonry Veneer Support Details: Thermal Bridging,” presented in June 2013 at the 12th Canadian Masonry Symposium by this article’s authors and James Higgins. The paper specifically discussed thermal bridging issues at various brick veneer support conditions, and reviewed thermal bridging impacts for different shelf angle support conditions.

Thermally efficient means of attaching the shelf angle can be achieved by de-bridging it from the concrete slab edge with knife plates, opposing angles, or proprietary attachment devices.

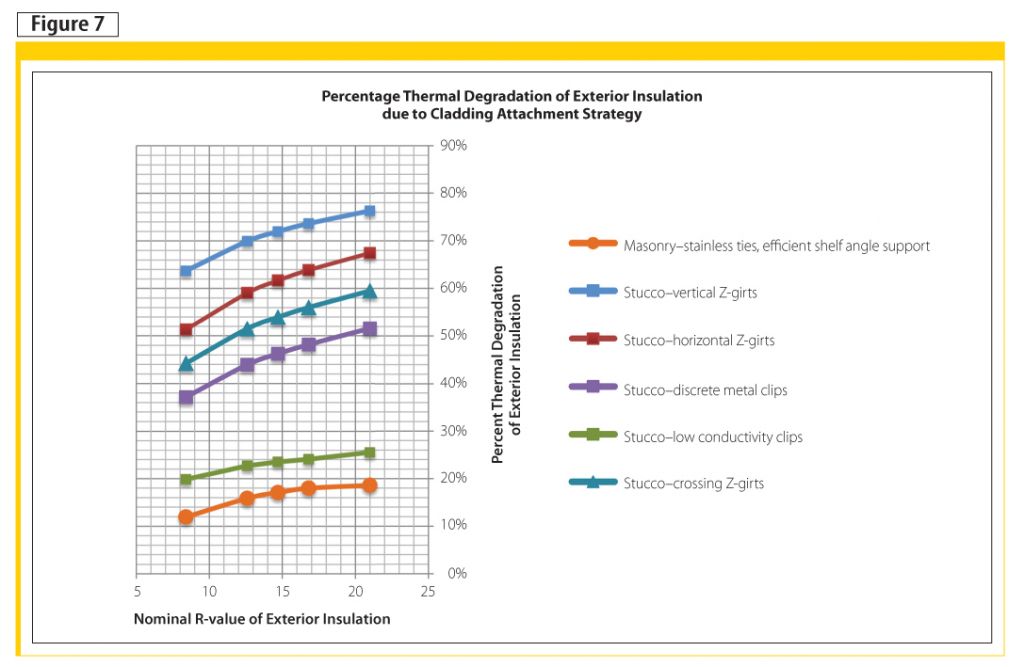

Figure 7 compares the impact of thermal bridging for various exterior insulated cladding assemblies with un-insulated steel stud backup walls. The cladding attachment configurations compared brick veneer with stainless steel ties and a thermally efficient shelf angle/slab support condition. The effective R-value for this brick veneer assembly can be compared to other typical cladding and attachment systems, such as continuous Z-girts (horizontal and vertical 18 gauge), intermittent 152-mm (6-in.) long 18-gauge clips, and low conductivity intermittent clips.

Brick veneer has the potential to be one of the most thermally efficient claddings. Compared to other assemblies, thinner amounts of insulation can be used to achieve the same effective R-value resulting in material and space cost savings and wall thickness. This is important for brick veneer assemblies, which tend to be thicker than other claddings. The results also demonstrate where effective R-value targets are in the R-15 to 20 range, this can be achieved with 76.2 to 101.6 mm (3 to 4 in.) of exterior insulation, whereas many other systems require considerably more insulation to do so, or cannot practically meet the requirements due to the amount of thermal bridging.

The impact of thermal bridging through the brick ties can be reduced to less than 10 per cent through use of efficient stainless steel and tie design. With careful consideration of the thermal bridging at shelf angle supports, one can expect reductions of the effective R-value of the exterior bridged insulation in the order of 16 to 20 per cent (combined shelf angle and ties).4 This is significantly better than the reductions of 50 to 80 per cent that can be seen with continuous Z-girts. Even some of the thermally optimized gravity/live load cladding attachment strategies have greater insulation reductions (i.e. greater than 20 per cent) than brick veneer. By accounting for impact of thermal bridging, brick veneer appears to be one of the most thermally efficient wall claddings.

Conclusion

Since thermal bridging at brick ties is significant, it should be accounted for when the actual thermal performance of the wall assembly is considered important. The thermal efficiency and durability of exterior insulated brick veneer wall assemblies has always been recognised in the industry. When actual performance and the full impact of thermal bridging is considered, well-designed brick veneer walls outperform most attached claddings.

Notes

1 For more, visit www.blocon.se.

2 The data was presented in a paper by Finch, Wilson, and Higgins entitled, “Thermal Bridging of Masonry Veneer Claddings & Energy Code Compliance” at the 12th Canadian Masonry Symposium, June 2013, in Vancouver.

3 The results are from a paper by Wilson, Finch, and Higgins entitled “Masonry Veneer Support Details: Thermal Bridging” also presented at the 12th CMS. This specifically discusses thermal bridging issues at various brick veneer support conditions.

4 Refer to 2012 CMS Conference paper, “Thermal Bridging of Masonry Veneer Claddings and Energy Code Compliance, by Finch,” Wilson, and Higgins.

Michael Wilson, M.Eng., P.Eng., FEC, is a managing principal and senior building science specialist at RDH Building Engineering in Victoria. He holds bachelor’s and master’s degrees in engineering. Wilson is a structural and building science engineer with specialized knowledge and experience in the field of masonry design and construction. He can be contacted at mjw@rdhbe.com.

Michael Wilson, M.Eng., P.Eng., FEC, is a managing principal and senior building science specialist at RDH Building Engineering in Victoria. He holds bachelor’s and master’s degrees in engineering. Wilson is a structural and building science engineer with specialized knowledge and experience in the field of masonry design and construction. He can be contacted at mjw@rdhbe.com.

Graham Finch, MASc, P.Eng., is a principal and building science research specialist at RDH Building Engineering in Vancouver. He holds bachelor’s and master’s degree in civil engineering. Finch specializes in applied research with advanced knowledge in the field of thermal modelling and hygrothermal analysis of building materials. He can be reached via e-mail at gfinch@rdhbe.com.

Graham Finch, MASc, P.Eng., is a principal and building science research specialist at RDH Building Engineering in Vancouver. He holds bachelor’s and master’s degree in civil engineering. Finch specializes in applied research with advanced knowledge in the field of thermal modelling and hygrothermal analysis of building materials. He can be reached via e-mail at gfinch@rdhbe.com.