The sustainability aspect of net-zero energy-ready build

By Tyler Simpson

The ecoEII Net Zero Energy Housing Demonstration Project with the National Research Council of Canada (NRC) gathered five production home builders from across Canada to build net-zero energy (NZE) market-ready homes with off-the-shelf technology. At the conclusion of the project, the builders constructed 11 NZE dwellings: one four-unit NZE row house, one NZE multi-unit residential building (MURB) comprising six units, and five net-zero energy ready (NZER) houses. The houses constructed represented an important step toward the broader adoption of low operational carbon houses and provided critical insight into how these homes could be constructed in a cost-effective manner.

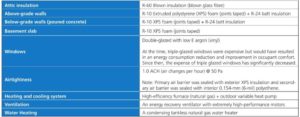

The recipe for a NZER or NZE house includes a building enclosure that incorporates optimized levels of insulation to limit thermal bridging, achieves exceptional levels of airtightness, engages fenestrations with a low U-value, and implements high-efficiency mechanical equipment. With this recipe in mind, and the support of a builder, the author’s NZER house, which was constructed in 2014, featured the following attributes as noted in Table 1.

With the parameters noted in Table 1, an energy model was developed in an energy simulation modelling software to approximate the house’s annual energy consumption, which revealed a utilization of 61 gigajoule (GJ) (Figure 1). If this house were built to the minimum requirements of the Supplementary Standards SB-12, amended in July 2016, from the Ontario Building Code (OBC), it would consume an additional 36 GJ of energy per year; which would mean less insulation, higher air leakage rate, and less efficient mechanical systems.

Further modelling revealed additional measures could have been taken to further reduce 61 GJ of energy consumption in the NZER houses, including the inclusion of triple-glazed windows and an air source heat pump hot water tank. These two measures would have reduced the annual energy consumption by another 10 to 15 GJ a year. At the time, both were expensive technologies to implement, but thankfully these costs have now come down and such measures can be implemented on projects to further reduce energy consumption.

Net-zero house and sustainability failures

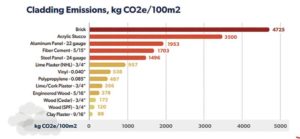

Before getting into how this house failed from a sustainability perspective, one must think about the definition of sustainability. Sustainability consists of fulfilling the needs of the current generations without compromising the needs of future generations. The NZER house constructed for the author considered operational carbon; however, at the time, an analysis of the embodied carbon was not completed. For a building to be truly sustainable, both the operational and embodied carbon must be low to ensure a limited negative impact on the environment. The three materials driving a high embodied carbon value for the NZER house include concrete, the brick cladding, and extruded polystyrene (XPS) insulation (Figure 2).

To reduce the embodied carbon of concrete, there are alternative mixes available such as supplementary cementing materials (SCMs). The SCMs replace a portion of the Portland cement, which improves the environmental footprint of concrete by a reduction in the greenhouse gas emissions (GHG) and air pollutants. Often, SCMs are byproducts from other industrial processes, so by using these materials in concrete mixes, materials are diverted from landfills. Bricks are also improving their environmental footprint with the introduction of manufactured bricks which do not require high temperature firing and limit the use of materials, such as Portland cement, in the manufacturing process. If low-carbon bricks are not available, alternative cladding options include fibre cement panels, or carbon capturing products, such as wood or wood composite claddings (Figure 3).

HFC versus GPS insulation

The graphic in Figure 2 could be referencing the old formulation of XPS foam insulation, however, is the new formulation any better and what is the difference between the two formulations? The old formulation of XPS is manufactured with HFC–134a as the blowing agent, whereas the new formulation is manufactured without the HFC–134a, or with a blend which limits its amount. The product received depends on the location.

As of January 2021, Environment and Climate Change Canada (ECCC) prohibit any individual to manufacture a foam product which contains a hydrofluorocarbon (HFC) blowing agent. In the U.S., the Environmental Protection Agency (EPA) stated that in 2015, the use of HFC–134a would end January 2021; however, it later retracted the mandate in favour of Proposed Rule 23, which was implemented under a program called Significant New Alternatives Policy (SNAP).1

The EPA will accept the use of HFC–134a in three specific “blends.” It should be noted only one XPS manufacturer was leading the charge against the revision, while other XPS manufacturers agreed they could produce a product without HFC–134a. In summary, any XPS product manufactured and sold in Canada cannot contain HFC–134a, while certain states in the U.S. allow XPS to use a blend of HFC–134a, while other states require XPS insulation without it.

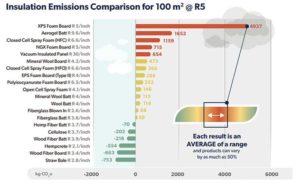

So, how much better is the new XPS formulation than the old formulation? How does a graphite expanded polystyrene rigid insulation (GPS) compare to XPS, and could it replace XPS foam insulation to achieve a sustainable solution for NZER or NZE housing? Often, individuals looking to build sustainable houses select expanded polystyrene (EPS) because its blowing agent, pentane, has a very low global warming potential (GWP). GPS is simply EPS insulation that has been infused with graphite to enhance the product’s thermal resistance. The new formulation of XPS insulation reduced its energy consumption during the manufacturing process by approximately 2.14 megajoule (MJ) (Table 2), a small but measurable amount.

Depending on the type of GPS insulation, the product will either have substantially lower energy consumption during the manufacturing process than XPS insulation or a slightly higher value. For some reason, the freshwater used in the manufacturing process increased by 0.09 m3 (23 gal) moving to the new formulation of XPS insulation and represents a freshwater usage which is roughly 40 times higher than a GPS insulation.

As advertised by the XPS manufacturer, there was a significant reduction in the total GWP due to the removal of HFC–134a. However, the GWP of the new XPS insulation is still two to three times higher than an equivalent GPS insulation. Although improvements have been made to XPS insulations formulation, the environmental attributes still rank it at the top compared to various other insulations (Figure 4). Material selection matters when developing sustainable houses with low embodied carbon and operational carbon. With a low embodied carbon and the preference of utilization by industry stakeholders interested in developing green buildings, GPS insulations are a good option for sustainable insulation and can be selected for a NZER or NZE house.

Over the past decade, there has been an explosion in demand from stakeholders within the construction industry, inquiring about the impacts to the environment from manufactured products. Individuals can view these impacts from an individual product environmental product declaration (EPD) or base it on an industry-wide average EPD. This document is a signal from a manufacturer or association representing various manufacturers and their commitment to measuring, and hopefully reducing, the environmental impacts of a product; it tells the life cycle story from the extraction of raw materials to the end-of-life use. Unfortunately, EPDs are single documents and there is no combined report which allows an individual to quickly compare products.

Builders for Climate Action have developed a tool called Building Emissions Accounting for Materials (BEAM). This tool allows an individual to calculate the approximate carbon emissions of their building, based on materials they typically choose, and see how those emissions can be reduced through a selection of alternative materials. To use the tool, an individual must simply input the dimensions of their building—low-and mid-rise residential buildings only—and a comprehensive list of all available materials will populate for each building assembly. Each material will have a carbon emissions value, which gives an opportunity to quickly compare materials and select a material fit for the scope of the project.2

Conclusion

This article sheds light on the importance of constructing houses with low operational carbon emissions through energy usage, as well as embodied carbon emissions through manufactured materials. As Chris Magwood from Builders for Climate Action notes, the building industry is good at reducing operational carbon emissions, however, the industry needs to stop developing high embodied carbon emission buildings and move toward low (moderate to zero) embodied carbon emission buildings, or store carbon instead over the next decade to limit the advancement of climate change. EPDs and tools such as BEAM help industry stakeholders evaluate and select which low carbon emission materials can be incorporated into sustainable buildings which meet the needs of current and future generations. Selecting foam insulation materials with low embodied carbon provides a platform for the development of an energy-efficient house with low operational carbon, and ensures embodied carbon has been limited as well.

Notes

1 Learn more about the Proposed Rule 23—Protection of Stratospheric Ozone: Listing of Substitutes under the Significant New Alternatives Policy Program (SNAP), www.epa.gov/snap/fact-sheet-proposed-rule-23-protection-stratospheric-ozone-listing-substitutes-under.

2 More information about Building Emissions Accounting for Materials (BEAM) can be found at BEAM Estimator, www.buildersforclimateaction.org/beam-estimator.html.

Tyler Simpson is a certified passive house designer and principal and founder of TWS Building Science. Rooted in and driven by a passion for building science, design solutions, and products represented by the firm allow the occupants to truly experience how a building should feel and perform. TWS Building Science is focused on providing high performance building enclosure solutions to building owners and industry professionals to achieve better built buildings that last for generations.