The nuances of glazing colour

Photo © Tom Kessler Photography

Colour measurement

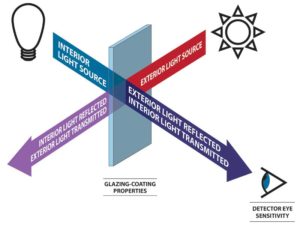

Glass is a unique material in that it has a transmitted colour (i.e. what is seen looking through the glass) and a reflected colour (i.e. what is seen looking at the glass, usually with some viewing angle). Therefore, the eye sees a blending of both the transmitted and reflected colours of the glazing simultaneously.

A spectrophotometer—a sophisticated instrument made up of a known light source, a sample holder or port, an integrating sphere to collect light, and a known light detector—is used to measure an object’s colour. Most spectrophotometers can measure both transmitted and reflected colour and have built-in software to calculate the measured colour of an object and provide numerical L*a*b* data, which can then be accurately compared to the colour of other objects without any subjectivity.

Glazing colour uniformity is formally defined or referenced in several industry standards published by ASTM International. ASTM C1376, Standard Specification for Pyrolytic and Vacuum Deposition Coatings on Flat Glass, and ASTM D2244, Standard Practice for Calculation of Colour Tolerances and Colour Differences from Instrumentally Measured Colour Coordinates, are the building glazing industry standards. They utilize L*a*b* colour measurements with the spectrophotometer oriented perpendicular to the glass surface.

ASTM C1376 sets the limit of the exterior colour uniformity range for pyrolytic- and vacuum deposition-coated flat glass both within a single glazed unit, and from one glazed unit to the next. It is important to note visually observable differences are possible within this specified range and and in conformance with the standard. ASTM C1376 also notes glass may have a perceived colour difference when viewed at various angles. This is a common phenomenon and does not necessarily indicate a product deficiency.

How low-e coatings affect light and colour

Low-e glass is often specified for IGUs and curtain wall assemblies because of its ability to transmit light and diminish heat gain, thereby increasing the energy efficiency of buildings. This glass type is formulated with multiple ultra-thin layers of materials—mainly silver and other metal oxides—on the surface of clear and tinted glass substrates of varying thicknesses.

Most often, this coating is deposited on the surface by magnetron sputter vacuum deposition (MSVD)—a high-tech process in which multiple nanolayers of heat- and light-controlling materials are applied to the glass surface one atom at a time. The optimal coating stack is only about 0.0002 times as thick as the glass lite onto which it is coated.

Chemical vapor deposition (CVD), an alternative, cost-effective coating process, is used more for adding tinted or reflective coatings, which can also have some low-e properties, to a glass substrate. The types of materials better suited to the CVD process are somewhat limited, and the coating layer thickness controls are not as precise as they are with the MSVD process. Therefore, the types of resultant coatings are also somewhat limited to tinted

and/or reflective, and the low-e properties are not as good as with silver-based MSVD coatings.

Even at these low levels of thickness, low-e coatings affect the light passing through, absorbed by, or reflecting off of them. The interaction between light, the coated glass, and the eye of the person looking at the glass relates directly to human perception of colour uniformity, as seen in Figure 3.

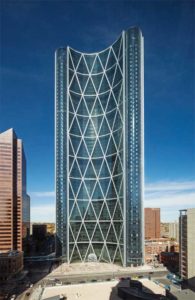

Low-e coatings can also increase the amount of reflection, which affects the perceived colour, especially when viewed from the building exterior. During certain conditions, such as a cloudy day, the reflected colour appearance may dominate, particularly when viewed against the dark background of an unfinished building interior. Ambient conditions also change with the time of day, as well as with the angle of the sun, depending on the viewer’s perspective, and whether one is seeing direct or indirect sunlight reflecting on the glazing.

However, once construction of the building is complete, the appearance of the glazing will change because the background and light coming from behind the glass emphasize transmitted colours and mute reflected colours. Consequently, colour differences visually perceived before construction is completed will often become more muted once the building is finished.