The greening of insulation materials

Image courtesy Elastochem

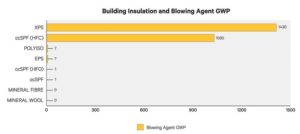

While it is difficult to measure the percentage of blowing agent released over the life of an insulation material, the 2018 Spray Polyurethane Foam Alliance (SPFA) environmental product declaration (EPD) estimates 10 per cent is released during manufacturing, 24 per cent when in use, and 16 per cent in a landfill. Though these numbers appear to have a significant effect on climate change, the overall life-cycle impacts from the use of some foam insulation products are still below other traditional, site-manufactured insulations.

Fibrous insulations types have high GWP impact upfront (i.e. burning coke, natural gas) whereas the majority of foam plastics using blowing agents have a continuous impact throughout its life cycle. Facings or coverings can affect the insulation’s overall GWP. However, the level of impact would depend on the type of finish (paper face, fibreglass matt, foil, etc.). Though these materials can be recycled, reused, or burnt for energy, they are landfilled at the end of their life cycles, and the resultant transportation has the least impact on GWP.

Image courtesy the Government of Canada

Regulatory amendments on HFCs

HFCs are being phased out as a result of the Montréal and Kyoto Protocols. Evolution of the refrigerant gas phase out is shown in Figure 3. The Montréal Protocol regulated chlorofluorocarbon (CFC) gasses as its impact on the ozone and global warming was high. Hydrochlorofluorocarbons (HCFCs) were the new, regulated refrigerant gasses due to its reduced impact on the ozone. GWP was addressed in the Montréal Protocol, but still had a large impact on global warming. The Kyoto Protocol aims to reduce GWP further.

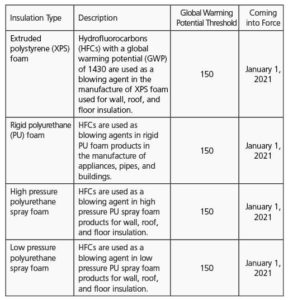

New regulations are coming to Canada in 2021. Starting January 1, 2021, all refrigerant gases over 150 GWP will be banned in Canada. This regulation will affect many industries using HFC gases including refrigerators, automotive and building A/C units, HVAC, and building materials.

The federal government has stipulated thermal insulations with HFC blowing agents, manufactured and brought into Canada, must have a GWP of 150 or less by the end of 2020 (Figure 4). It will be important for architects and specification writers to understand these new requirements and update their master specifications and technical documents accordingly.

The next generation of blowing agents

Several foam insulation manufacturers in Canada have already made changes to their blowing agents. The ISO board stock insulation industry made these changes approximately 20 years ago, but the negative side-effect was a reduction in RSI values at cold temperatures. ISO companies are currently working on solutions to minimize the impact of cold temperature on their products. Prior to the ISO industry switching to pentane, the GWP of ISO blowing agent was similar to XPS. A ccSPF with hydrofluoroolefin (HFO) blowing agent was launched approximately five years ago. While there are several ccSPF manufactures in Canada, only a handful have a product ready to meet the 2021 regulation. SPF suppliers currently use two ultra-low GWP blowing agents—Honeywell’s nonflammable blowing agent Solstice with a GWP of 1 and Chemours non-flammable blowing agent Opteon 1100 with a GWP of 2. These are below the maximum GWP established by Environment Canada. The EPS industry does not have to change blowing agents as they are within the GWP-150 requirement. XPS manufacturers are still developing a low-GWP blowing agent solution for Canada.