The greening of insulation materials

By Rockford Boyer

The construction industry has a large impact on climate change through building design, material manufacturing, construction activities, building operations, and decommissioning. There is a huge opportunity for the sector to reduce its negative effects with proper design, use of assemblies with low global warming potential (GWP), efficient building operation and energy utilization, and material reuse and recycling after demolition (if carbon neutral or carbon-negative). GWP measures the ability of greenhouse gases (GHGs) to trap heat in the atmosphere.

This article focuses on the climate change potential of thermal insulation materials. According to the Pan-Canadian Framework on Clean Growth and Climate Change, “The cost of inaction is greater than the cost of action: climate change could cost Canada $21 to $43 billion per year by 2050, per 2011 estimates from the National Round Table on the Environment and the Economy.”

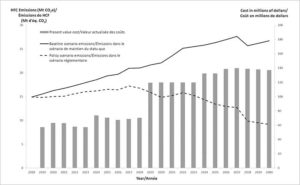

Image courtesy the Government of Canada

When it comes to conversations around global warming, insulation is interesting as it can have a negative net impact when considering factors such as raw material extraction, transportation, manufacturing, and end-of-life disposal. On the other hand, it reduces the impact of climate change from the how the buildings are conditioned.

The impact of insulation

There is confusion about the effect of insulation materials on climate change. A common misconception on the climatic impact of factory-manufactured insulating materials is “it has zero global warming potential, as the finished thermal insulation material does not contain blowing agents with high GWP.” Traditional commercial insulation types can be divided into two distinct groups. The first group comprises materials that trap air to obtain the RSI value (thermal resistance), such as fibrous insulation and open cell foams. The second group includes insulation materials that trap a higher RSI-value gas (blowing agents) in their cells to obtain a higher RSI value. The blowing agents used in closed-cell board foams and spray-applied foams have an impact on climate change. However, with the new blowing agent requirements set out by Environment Canada, the impact from blowing agents (hydrofluorocarbons [HFCs]) will be drastically reduced in the coming years. Figure 1 indicates the predicted trend in HFC emissions if the new environmental policy is enforced. The predicted reductions in HFC emissions for the next 20 years would be approximately 166 (Mt C02e).

Closed-cell foam insulations, both board stock and spray applied, use various commercially available HFC blowing agents to achieve the product’s thermal performances. The most common foam products on the market using blowing agents are expanded and extruded polystyrene (EPS and XPS), polyisocyanurate (ISO), and sprayed polyurethane foam (ccSPF). The chemical composition of the blowing agents will impact climate change through their radiative efficiency (ability to absorb energy) and by their lifetime (length of stay in the upper atmosphere). The GWP of blowing agents are compared to a baseline carbon dioxide (CO2) gas assigned at GWP 1. Figure 2 provides a list of closed-cell materials and their GWP ratings.