The detrimental effects of UV on barriers

Getting ahead of UV damage

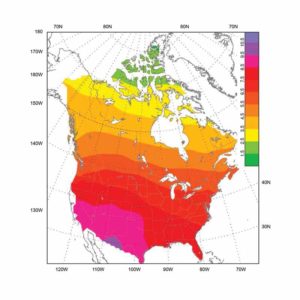

Image courtesy World Ozone and Ultraviolet Radiation Data Centre

Many building professionals instinctively turn to manufacturer data sheets for the information they need to select products. In the case of long-term UV exposure, there is no ASTM standard on which manufacturers may base their claim of acceptable jobsite exposure times. However, if this recent UV research has proven anything, it is that more needs to be done outside of this effort to find a solution that best suits the needs of the project. Below are some simple steps to consider when selecting a product.

Know the UV radiation expectations at the site

Understanding the UV radiation expectations at the site can help building professionals plan appropriately for optimal product selection and time demands for exterior cladding installation. For instance, Figure 1 illustrates the UV index for North America in July.

Minimize exposure of WRB to UV

It is advisable to include specifications and schedule details to install the exterior insulation or cladding as soon as possible after the installation of the WRB. By minimizing exposure, one can limit the impact UV will have on long-term performance.

Revisit the impact of failed WRBs used in the past

If building professionals experienced the negative effects of a failed WRB in past projects, it is best to remember the exposure time on that site.

Ask the manufacturer for more information

Reaching out to the WRB manufacturer for more information will come in handy. They should provide information on how the product is manufactured, and some may have data specific to the long-term performance of the material, as well as recommend UV exposure times. Others, however, may not have any test results. It is important to remember a manufacturer’s representative cannot detect molecular damage through a visual check.

Conclusion

Deciding on the best WRB for a project should rely on more than the information provided in manufacturers’ marketing materials. Understanding specific project challenges, exposure rates, schedule demands, and WRB needs will ultimately help one give better results, extend the life of the building, and provide the best performance.

Peter Barrett is the product and marketing manager for Dörken Systems. He has been with the company for more than 12 years. However, his involvement with the design community and building materials industry spans over 25 years. Barrett holds a BA (Hons.) from Queen’s University, Kingston, Ont., and an MBA from Wilfrid Laurier University, Waterloo, Ont. Barrett is a board member of the Air Barrier Association of America (ABAA). He can be reached at pbarrett@dorken.com.

Peter Barrett is the product and marketing manager for Dörken Systems. He has been with the company for more than 12 years. However, his involvement with the design community and building materials industry spans over 25 years. Barrett holds a BA (Hons.) from Queen’s University, Kingston, Ont., and an MBA from Wilfrid Laurier University, Waterloo, Ont. Barrett is a board member of the Air Barrier Association of America (ABAA). He can be reached at pbarrett@dorken.com.