The air/vapour barrier must die

When saturated air encounters a cooler surface, the moisture it is carrying undergoes a phase change and condenses (i.e. turns from gas to liquid) on the surface. The temperature at which this occurs is known as the dewpoint. This becomes critical in building envelope design because uncontrolled air leakage can result in air entering and condensing on components of wall cavities in unintended ways, leading to moisture-related problems such as mould, corrosion, and the general deterioration of building materials.

Air barriers are installed to counteract these undesirable effects, and must at a minimum possess some essential properties.

Resistant to air leakage

This resistance is quantified through testing according to industry standards (Underwriters Laboratories of Canada [CAN/ULC] S741, Standard For Air Barrier Materials–Specification in Canada, and ASTM E2178, Standard Test Method for Air Permeance of Building Materials, in the United States). Air leakage is limited in the National Building Code of Canada (NBC) to 0.02 L/(s·m2) (0.004 cfm/sf) of leakage at a pressure differential of 75 pa (1.57 psf).

Be continuous

As shown by research, air leakage is a critical factor when it comes to ensuring proper building envelope performance. Therefore, NBC mandates materials employed to preserve the airtightness of building assemblies must be installed in a continuous fashion.

Act as a system

Contrary to popular belief, the air barrier does not manifest itself as a single material. Even if there is a primary air barrier material (usually referred to as the air barrier membrane), it is the combination of this primary material and various other components (e.g. doors and windows) as well as accessories (e.g. sealants and tapes) performing in unison that truly guard the building against the deleterious effects of air leakage. This systemic approach is recognized in CAN/ULC S742, Standard For Air Barrier Assemblies–Specification, as it attempts to mimic actual field conditions (e.g. penetrations, laps, and reinforcements) rather than evaluate the performance of materials in isolation (Read the blog “Do You Know the Canadian Air Barrier Standards CAN/ULC-S741 AND S742?” by Jean-François Côté.).

Vapour retarders (or vapour barriers) serve a much different purpose than air barriers. They are designed to stop (or slow) the movement of water in its gaseous form from travelling through wall assemblies. This process, called vapour diffusion, is the motion of water vapour molecules from an area of high concentration (higher humidity) to an area of low concentration (lower humidity) across a gradient (vapour permeable material). This movement is driven largely by kinetic forces at the molecular level and is governed by temperature and relative humidity (RH), not air pressure.

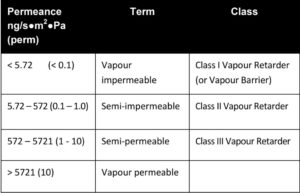

Vapour permeance (colloquially referred to as “perm rating”) is a measure of a material’s ability to allow the passage of moisture by diffusion. This measurement is expressed in ng/s●m2●Pa (nanogram per second per square metre per pascal) or in perms, and is often evaluated in accordance with ASTM E96, Standard Test Methods for Water Vapor Transmission of Materials. U.S. building codes have classified materials according to their vapour permeance on a scale ranging from “vapour impermeable” to “vapour permeable” and assigned them to “vapour retarder classes” ranging from I to III (Refer to J. Lstiburek’s 2011 paper on “Understanding Vapor Barriers.”). In principle, only materials meeting the requirements of a “Class I Vapour Retarder” should be called “vapour barriers” (Figure 1).

Diffusion rates through wall assemblies have been shown to be generally slow. All things being equal, breaches in the vapour barrier result in significantly lower quantities of moisture migration as a result of diffusion rather than the quantity of moisture transported through the same material due to air movement. As such—despite what many often assume—vapour barriers need not be continuous in wall assemblies, and may, at times, (depending on climate) be omitted altogether.

Different meanings

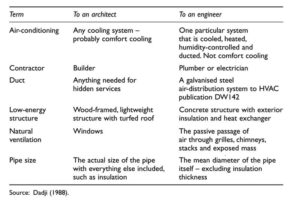

The importance of effective communication in the construction industry cannot be overstated. However, barriers (no pun intended) exist that can impede or distort effective communication and result in failure or undesirable effects. Amongst these barriers, the use of jargon is often cited as a leading cause of communication breakdown. Specifically, in the construction industry—due to its fragmented structure, technical nature, and the adversarial tendencies of its stakeholders—the lack of terminology standardization has engendered different terms and meanings that are understood differently by various people. Figure 2 illustrates how misunderstandings can occur between two professionals interpreting technical jargon differently. Unfortunately, these complex and ambiguous terms, often well-understood by discrete groups, but prone to misinterpretation by others, plague the industry.

The term “air/vapour barrier” is an example of such ambiguous terminology. The ambiguity of this term is inherent in its use of the slash ( / ) punctuation mark. In English, the slash can be used to either denote the conjunction “or” or the conjunction “and.” Therefore, in theory, the term “air/vapour barrier” can be interpreted as “air or vapour barrier” or “air and vapour barrier.” In general context, however, it is safe to assume most people use it to refer to the latter. Yet, as it has been discussed previously, the term “vapour barrier” is itself a subset of the term “vapour retarder” (i.e. only a Class I vapour retarder is considered a vapour barrier). Should the term “air/vapour barrier” then be restricted to materials meeting the requirements for air barrier materials and Class I vapour retarders? The advent of materials having various levels of permeability (e.g. spun-bonded polyolefin, silicone, and vapour permeable polyurethane foam) clearly show such a restriction would prove overly exclusive.

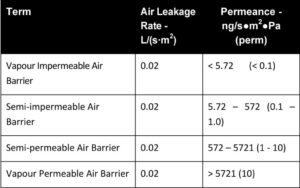

Any alternative to “air/vapour barrier” should reduce ambiguity while reflecting the current trends of the industry. At present, it is crystal clear the benefits of controlling air leakage far outweigh the control of vapour diffusion. Therefore, “air/vapour barrier” should be replaced with a term describing an air barrier material, which also has some vapour-retarding characteristics. As the permeability of materials has already been standardized in building codes, it is perhaps most appropriate to borrow this terminology and apply it to our problem. See Figure 3 for a proposed system with four distinct designations and associated properties.

Conclusion

It is no secret the construction industry is plagued by a chronic productivity problem. A 2015 report by McKinsey & Company showed that while productivity rates in the manufacturing sector nearly doubled over the 20-year period spanning from 1995 to 2015, productivity rates remained painfully flat, or even worsened, in the construction industry (Check out the 2015 article, “The construction productivity imperative,” by C. Sriram, A. Mohammad, and Mark van Nieuwland.). Factors such as the fragmented structure of the industry, the cyclical nature of construction activities, and poor or inadequate communication have all been suggested as contributors to this lack of productivity growth. Moreover, these sluggish gains may also be reflective of the industry’s unwillingness to embrace change.

The future is, however, not all bleak. Recent years have shown consultants and contractors alike embracing new technologies such as building information modelling (BIM), drones, and prefabrication to increase output and reduce errors. Accordingly, the language used in construction today must express and reflect the current state of affairs. Terms and materials no longer serving their purpose should be replaced with new ones illustrating advancements in research and practice.

Thus, the term “air/vapour barrier” should be replaced by terms illustrating both the air leakage and vapour permeance properties of these materials. Ultimately, the biggest challenge to any term proposed will be to overcome the inertia forces associated with the construction industry’s fear of change.

Juste Fanou is the director of Jm|F Technical Documentation Solutions Inc. He is a bilingual technical documentation specialist and specifications writer with more than 10 years of experience. Fanou has assisted multiple clients in the development of front-end and technical specifications including evaluation of material substitution proposals and the interpretation of standards. He holds a diploma in architectural technology and a degree in civil engineering technology. Fanou can be reached at jfanou@jmfservices.net.

Juste Fanou is the director of Jm|F Technical Documentation Solutions Inc. He is a bilingual technical documentation specialist and specifications writer with more than 10 years of experience. Fanou has assisted multiple clients in the development of front-end and technical specifications including evaluation of material substitution proposals and the interpretation of standards. He holds a diploma in architectural technology and a degree in civil engineering technology. Fanou can be reached at jfanou@jmfservices.net.