The advantages of designing for IAQ

Other key performance comparisons

For high-efficiency filtration, there are other key indicators that are as important as a filter’s rating or its ability to remove particles and other airborne contaminants from the air. There are two that most impact an IAQ strategy.

Dust-holding capacity

In addition to the pressure impact this produces, dust-holding capacity is the best indicator of how long a filter will last. For instance, a 51-mm (2-in.), MERV 13, 610 x 610-mm (24 x 24-in.) filter holds approximately 40 g (1.3 oz.) of dust before reaching its dirty design static pressure of 36 mm (1.4 in.) water. Therefore, if the average building produces 130 g of dust per cubic metre each month, or 48 g per 610 x 610-mm filter, one would have to replace a 51-mm deep MERV 13 filter every two weeks and a 102-mm (4-in.) deep MERV 13 filter every month to keep the static below 36 mm (1.4 in.) water and maintain a mid-life static pressure of around 23 mm (0.9 in.) water, not including the impact from a pre-filter.

By comparison, some polarized-media electronic air cleaners can hold up to 1600 g (51.4 oz.) of dust at the recommended change state of 15 mm (0.6 in.) water, or twice its initial static pressure. An air cleaner that holds 10 times the dust of cartridge and bag filters and up to 100 times the dust of shallow-bed passive filters will greatly impact maintenance intervals and other ongoing costs of filtration.

Pressure drop (resistance to airflow)

The pressure drop is another important performance measurement. Any filter in the air stream increases resistance and reduces flow. This is an important consideration for designing a forced air distribution system. Electronic air cleaners offer relatively low resistance. With passive filters, the static pressure increases with efficiency.

Additionally, lower static pressure directly corresponds to lower brake horsepower. Since brake horsepower drives fan energy and so on, lower static pressure corresponds directly to energy savings.

In a recent amendment within ASHRAE 90.1-2007, Energy Standard for Buildings Except Low-rise Residential Buildings, the allowable brake horsepower for each type of system and space use has been clarified. Section 6.5, “HVAC Air System Design and Control,” sets allowances for brake horsepower based on system type and application. Often, these levels can be difficult to meet with traditional passive filtration.

The role of ventilation

Ventilation has traditionally been the most widely used means of addressing airborne contaminants. In commercial buildings, most codes rely on ventilation rates specified by ANSI/ASHRAE 62.1-2010, Ventilation for Acceptable Indoor Air Quality. Today’s standard has two methods for determining the necessary outdoor air levels: the ventilation rate procedure and the more recent IAQ procedure.

The ventilation rate procedure is the easier of the two to apply and most buildings are designed and operated under its guidelines. The ventilation standard specifies a certain number of cubic feet per minute per person for various building types. For example, in office spaces and schools, the HVAC system must bring in 22 to 27 m3/hr (13 to 16 cfm) per person of outdoor air, depending on occupant density. When the ventilation rates were adopted in 1989, two things were assumed—the only means of dealing with contaminants in the space is by dilution with outdoor air (i.e. there is no air cleaning), and the outdoor air level is sufficient to accommodate ‘moderate smoking’ (based on 30 per cent of the occupants smoking one cigarette per hour). Later, standards were amended to allow 25 m3/hr (15 cfm) per person in non-smoking offices. Today, the ventilation standard also requires outdoor air quality meet certain criteria. In practice, however, this is something not often determined or monitored.

The IAQ procedure allows for greater fine-tuning and more efficient operation of the HVAC system and the outdoor air levels. However, because it uses a series of complex calculations, it is less straightforward to use than the ventilation rate procedure. The IAQ procedure essentially gives designers and operators outdoor air credit for things such as no smoking, good airflow patterns, and air cleaning. ASHRAE has developed formulas for calculating contaminant levels in a space and guidelines as to what levels are of concern. Simulation programs can put the data into easily interpretable formats that make meaningful predictions for carbon dioxide (CO2) and contaminant levels.

Operational savings from reduced ventilation

In a typical building with no smoking and no unusual contaminant sources, outdoor air levels can often be reduced from 22 to 27 m3/hr per person to between 13 and 17 m3/hr (7.5 and 10 cfm) per person. Such a reduction can yield significant operational savings. For example, in a small office building with a 60-tonne rooftop unit, annual savings on utility costs alone can be expected to be in the range of $3000 to $12,000, depending on the building’s geographic location (hot, humid climates have the greatest costs/savings), the utility rates, and the hours of operation.

The other benefit to this approach is outdoor ventilation air does not inadvertently create IAQ issues. As discussed, in many urban environments, outdoor air is usually more polluted than indoor air. For example, in the monitoring of black carbon and ultra-fine particle levels (< 0.1 µ [about 0.004 mils] in size) inside and outside an office building in a 2010 Washington, D.C., study, the indoor levels were 92 to 99 per cent lower than those outdoors. Bringing dirty outside air inside does not improve IAQ, whereas cleaning and re-using the indoor air does.

Reduced outside air can also favourably impact equipment selection, sometimes translating into smaller equipment. This can have the net effect of essentially paying for the filtration system on the project.

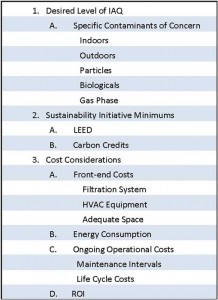

Designing for the right IAQ strategy

The first step is to decide which airborne contaminants need controlling. The most effective filters tend to cost the most, so the decision should balance the price against the effectiveness needed. Vehicle emissions or combustion gases require a filter that removes much smaller particles, such as an electronic air cleaner, polarized-media air cleaner, or HEPA or ULPA filter. The electronic air cleaner can be a good choice given effectiveness on a wide range of particle sizes and the low pressure drop. HEPA and ULPA filters are the most effective, but create significant pressure drop, and replacement costs can be high.

Issues with odours and/or volatile organic compounds (VOCs) will also impact the filtration type. Pet stores, hair salons, medical buildings, and assisted living facilities are just a few examples where odour and VOC issues can be expected. The most popular technologies that address these gas phase contaminants include polarized-media air cleaners, carbon filters, and photocatalytic oxidation (PCO). Technologies that address biologicals (i.e. living airborne organisms) include polarized-media air cleaner HEPA and ULPA filters, and ultraviolet (UV) lamps. The most widely used germicidal lamps operate in the C band (UV-C).

The second step is to determine if any sustainability initiatives will impact equipment selection. LEED certification, for example, requires a minimum of MERV 13 for New Construction (NC) v2.2, EQ Credit 5. Additional LEED points may be available in other areas. Reducing HVAC energy, for example, qualifies for a point under Energy and Atmosphere (EA) Credit 1, Optimize Energy Performance. The availability of carbon credits, which are popular in the European community, is also impacted by energy savings.

The third step is to compare the initial price to the trade-offs in lifecycle and operating costs. This becomes increasingly important as the need for high-efficiency filtration rises. With this also comes providing for adequate space for the mechanical systems. Static pressure and ventilation air greatly impact energy consumption. The service replacement expenses and length of maintenance intervals influence ongoing operational costs. These should be reviewed to determine the system return on investment (ROI). In some cases, a high-efficiency filtration system, where there is a need for high-efficiency filters, can pay for themselves in just a few years.

Case in point

Victoria, B.C.’s 947 Fort Street building is a 4088-m2 (44,000-sf), six-storey, class ‘A’ office tower. The development is a landmark building on Fort Street, which already features a vibrant and eclectic mix of retailers, restaurants, and street front professional offices. The structure is ideally located along one of Victoria’s main arterial bus, car, and bicycle routes.

Designed by Genivar (formerly HWT Consultants), the facility was constructed as a LEED Gold-certified office building. Polarized-media air cleaning systems were included as one of the building’s design elements. Developers saw the value of incorporating indoor atmospheric quality management plans and programs into the project design to increase IAQ during occupancy. In addition to adding value offered by a superior indoor environment, developers also recognized the filtration system would add to the building’s sustainability and reduce operating costs. The system features a low air pressure drop relative to 80 per cent or greater passive mechanical filters. This reduces required fan energy and lowers energy consumption, which helps earn LEED points. The system also features a very high dust-holding capacity that extends filter replacement schedules from months to years.

The polarized-media electronic air cleaners installed in a custom air handling unit (AHU) also feature a heat wheel which provides clean, tempered air to hybrid heat pumps. These pumps use the compressors for cooling only, and use hot water coils for heating. The project also includes an air to water heat pump on the roof. The pump plant operates much the same as geothermal, but in Victoria’s moderate climate, it uses air as the heat transfer source to provide heating and cooling for the building.

Quantifiable benefits of an IAQ strategy

The construction industry has made great progress in implementing energy-saving strategies that improve building efficiency and carbon footprint. Nearly all of them, however, are geared to reduce heating and cooling system consumption. The absence of an effective IAQ strategy in the design stage can lead to problems including health risks, annoying odours, high energy consumption, and excessive operational costs.

The advantages to having an effective IAQ strategy are many. Studies have shown better indoor air quality improves health, well-being, and productivity. (For more, see “Health and Productivity Gains from Better Indoor Environments and their Relationship with Building Energy Efficiency,” by William J. Fisk in the Annual Review of Energy and the Environment (vol. 25, 2000). Also see “Estimates of Improved Productivity and Health from Better Indoor Environments” by William J. Fisk and Arthur H. Rosenfeld in Indoor Air: International Journal of Indoor Environment and Health (vol. 7, issue 3, 2007), and the Occupational Health & Safety’s (OH&S’s) “IAQ and Worker Productivity.” Visit ohsonline.com/articles/2010/09/01/iaq-and-worker-productivity.aspx). Careful planning can eliminate nuisance issues down the road. Today, there are air cleaners available that extend maintenance intervals from months to years. There are even systems can actually pay for themselves through lower operating costs.

Robert F. Goodfellow, IAQCP, is vice-president of marketing with Dynamic Air Quality Solutions. He has more than 20 years of experience in the heating, ventilation, air-conditioning, and refrigeration industry. Goodfellow can be reached via e-mail at rgoodfellow@dynamicaqs.com.