The advantages of designing for IAQ

By Robert F. Goodfellow, IAQCP

There are many advantages to having an effective indoor air quality (IAQ) strategy, which may not always include the obvious––breathing clean air. After all, most people now spend an average of 90 per cent of time indoors. (See the U.S. Environmental Protection Agency’s (EPA’s) “An Introduction to Indoor Air Quality (IAQ).” Visit www.epa.gov/iaq/voc.html).

One needs to look at the technologies that improve IAQ and address specific problems. From there, one can give some insight into the many less obvious potential advantages of a successful IAQ strategy.

IAQ overview

Today’s predominant indoor air quality strategies are largely a holdover from 20 or 30 years ago when smoking was still prevalent indoors. Building construction was getting tighter following the oil embargos of the 1970s––which served to lock in pollutants––and increasing ventilation air was still seen as the best way to purge indoor contaminants. Today, inside air is cleaner without the smoke, but there is still a vast array of other pollutants present indoors, including those from:

- adhesives;

- building materials (including finishes for walls, ceilings, and floors);

- cleaning chemicals;

- deodorizers;

- disinfectant sprays;

- insecticides;

- paints; and

- stains.

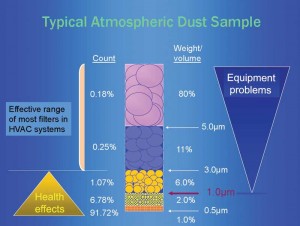

Throughout the last century, HVAC filters were used primarily to protect HVAC equipment, not the building occupants. Larger dust particles created the biggest problems, so filters were developed to trap them. Submicron particles, because they did not adversely affect equipment performance, went largely ignored. Today, there are many IAQ products and solutions that allow designers the opportunity to customize an IAQ strategy based on occupant needs.

Images courtesy Dynamic Air Quality Solutions

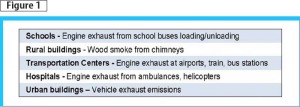

Outdoor air is the most common source of IAQ problems in a building. Proximity to industries, busy highways, or other sources of polluted air can allow the entrainment of particles and odours into air intake vents. With the banning of smoking and today’s modern sustainable building materials, outdoor air is typically more polluted than indoor air in any urban environment. Figure 1 gives several examples where outdoor air quality can affect IAQ.

Identifying contaminants of concern

There are three types of airborne contaminants: particles, biological, and gas phase.

- Particles––the smallest submicron particles are inhaled into lungs and become absorbed in bodies and bloodstreams, causing asthma and allergy symptoms.

- Biological––flu viruses, germs, and other airborne pathogens are expelled into the air by a cough or sneeze, causing colds and flu.

- Gas phase––airborne chemicals such as pesticides and cleaning materials can create toxic compounds that are simply re-circulated in the space causing headaches, dizziness, and other ailments.

The ambient air outdoors in a typical urban environment contains about 35 million particles (in the size range of 0.5 µ [about 0.02 mils] or larger in diameter) per cubic metre. By weight, the volume over 0.5 µ represents about 99 per cent. However, by particle count, the same particles represent only about eight per cent. This means the overwhelming majority of airborne particles are invisible to the naked eye.

Airborne contaminants that measure below 0.5 µ in size are potentially detrimental to health because they are absorbed through lungs into bodies. Low-efficiency filters cannot remove these contaminants from the air.

Conventional filtration technologies and mechanisms

Passive, mechanical filters are common, accounting for more than 90 per cent of all HVAC filters because of their low price and large number of users.

Usually consisting of a loose pad of coarse fibres, and sometimes coated with a light adhesive to help large particles stick, these filters screen out only large particles, and have virtually no effect on airborne materials that cause allergies or sickness. Passive filters work like a sieve. The sizes of particles collected depend on the density of the filter media. The trade-off for a denser, more efficient filter is pressure drop. Passive filters also include pleated filters, which use a finer mesh and catch smaller particles. Since the finer mesh also creates more resistance to airflow, the surface is ‘extended’ with pleats to offer more surface area for air to pass through. Pleated filters are usually 25 to 152 mm (1 to 6 in.) thick.

High-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filters are also passive filters. (High-efficiency particulate air (HEPA) filters are rated 99.99 per cent efficient with particles 0.3 µ and larger in diameter, while ultra-low penetration air (ULPA) filters are rated 99.99 per cent efficient with particles 0.12 µ in diameter). They contain hundreds of square feet of filter paper folded into a couple of square feet of space. They remove very small particles, including some viruses. Since they are several inches thick, they require duct modifications. Bypass HEPA filters only clean a small percentage of air as it bypasses the primary HVAC system to avoid excessive pressure drops.

Passive electrostatic filters have polypropylene fibres that pick up a static charge as the air passes over them. The charge helps hold fine particles and gives it greater efficiency than comparable passive media. Designed primarily for residential use, these filters are washable and can be reused. Since the charge is passive, it can wear off over time as fibres become coated. Depending on the density of the fibres, passive electrostatic filters can also have a higher static pressure drop. The higher the pressure drop, the more energy it takes to push air through the system, and the greater the wear on the air-moving equipment.

Electronic air cleaners

There are many kinds of electronic air cleaners, the most common of which are electrostatic precipitators, popularized in the 1980s. They consist of ionizing wires that charge airborne matter, and charged collector plates. The particles are reflected by oppositely charged plates, and collected on grounded plates. Electrostatic precipitators are generally the most effective at removing submicron particles (e.g. mist and smoke), rather than larger ones (e.g. dust and grains). Electrostatic precipitators have a very low static resistance to airflow but require more frequent maintenance. Once ionizing wires and/or collector plates become coated, performance drops off. Most electronic air cleaners draw between 20 and 40 W. (See Frost & Sullivan’s “North American HVAC Air Filters Markets” from March 2005. Visit www.frost.com/prod/servlet/report-brochure.pag?id=A994-01-00-00-00#report-technologies).

Another type of electronic air cleaner is the active electrostatic or polarized-media air cleaner. This air cleaner does not create charged particles or ozone and draws between 2 and 6 W. Polarized-media air cleaners use mechanisms of both passive filters and electronic air cleaners in addition to agglomeration:

- Passive mechanisms––a sparse disposable media pad uses all the mechanisms associated with passive filters.

- Electrostatic attraction––a conductor in the media pad is electronically enhanced to produce an electric field that polarizes the particles, giving them negative and positive poles. The particles are then collected on the media fibres.

- Agglomeration––uncollected particles having passed through the polarized media agglomerate to other polarized particles, chemicals, and gas phase contaminants to form larger particles that are collected on subsequent passes. Like passive filters, polarized-media air cleaners increase in efficiency as they load. However, they have a higher dust-holding capacity to load more evenly and extend service life.

Carbon filters, usually configured in cells or trays, are used primarily for removing odours, vapours, and gases through adsorption. The material attracts and holds gases and vapours in its pores, thereby eliminating odours. Carbon filtration systems are more expensive than traditional filters.

Filter performance tests: what do they mean?

There are various tests used to measure filter performance. Unfortunately, some are designed for passive filters and some for air cleaners, and others only measure single-pass efficiency.

MERV

The most common benchmark for filter efficiency is the minimum efficiency reporting value (MERV), a testing protocol designed in 1987 as American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) 52.2, Method of Testing General Ventilation Air-cleaning Devices for Removal Efficiency by Particle Size. The standard rates the effectiveness of clean, passive HVAC filters. MERV uses conductive dust in a single-pass test to measure passive filter performance and is not applicable to electronic air cleaners or air cleaners using multiple air exchanges.

Many building practices rely on MERV. Hospitals, for example, often require pre-filters of MERV 8, and MERV 13 or 14 final filtration. The Leadership in Energy and Environmental Design (LEED) system encourages sustainable green building and development practices through various performance criteria. One point is available for indoor environmental quality if the filter or air cleaner achieves a minimum of MERV 13 under Indoor Environmental Quality (EQ) Credit 5, Indoor Chemical and Pollutant Source Control. However, the program does not distinguish between filters or electronic air cleaners.

CADR

Clean air delivery rate (CADR) is a measurement resulting from testing procedures developed as American National Standards Institute/Association of Home Appliance Manufacturers (ANSI/AHAM) AC-1-1988, Portable Household Electric Cord-connected Room Air Cleaners. The test is performed in a 28.5-m3 (1006.5-cf) chamber with a circulating fan. It uses a logarithmic regression to compare particles’ removal rate by an air cleaner to the natural decay rate within the chamber over 10 or 20 minutes.

Thermal DOP efficiency

Thermal dioctyl phthalate (DOP) efficiency refers to another test specific to the very highest efficiency passive filters, including HEPA filters, using a heated aerosol mist of dioctyl phthalate.

The efficacy of different filters varies depending on particle size. Higher efficiency is usually better, but it can get complicated. Some filters may catch all the lint, but few catch the smaller particles. The filters that perform best across the entire range of particle sizes are HEPA filters and electronic air cleaners.