Tankless Technologies: Selecting commercial water-heating systems to save energy, prevent shutdowns, and provide on-demand hot water

Peace of mind through redundancy

As mentioned, linking multiple units means never having to worry about one faulty heater shutting down all hot-water production. The system is designed to always meet demand. In the extreme case all remaining heaters have reached maximum demand, the flow rate will slightly be reduced to lower the BTU input and maintain the set point temperature. In a conventional storage-tank system, failure of this single unit can put the entire domestic hot-water operation in jeopardy.

Installation savings

Specifiers, installers, and building owners may have concerns about the costs associated with installing multiple tankless units. However, tankless may not be more expensive, even in terms of upfront costs. It is also possible to supplement the system with a storage tank. This will allow fewer tankless units to be installed without losing the ability to modulate Btus.

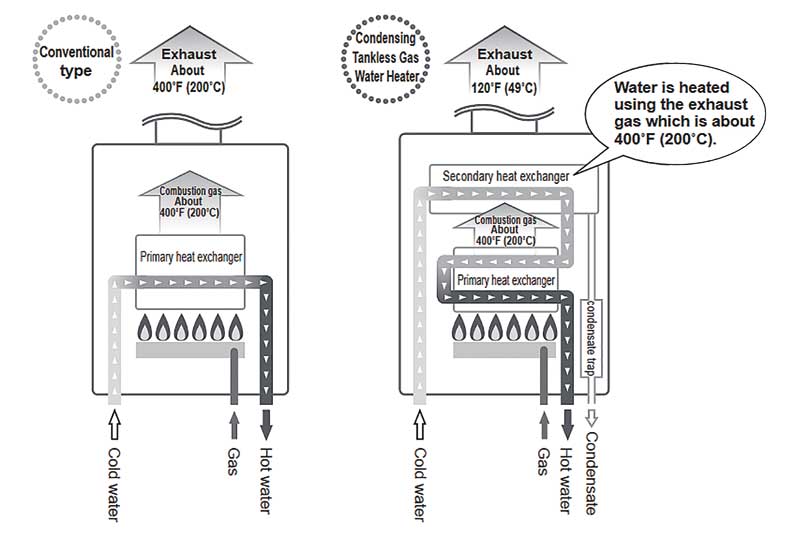

Another option is to order a prefabricated rack system that streamlines installation costs by preassembling and preprogramming multiple units in a standard manifold for a particular application. The rack can come pre-engineered with isolation valves, system, and pump controllers. If condensing heaters are chosen, their cooler exhaust gases will allow for PVC venting instead of stainless steel, further reducing costs.

For those accustomed to using storage tank heaters, another point to keep in mind is tanks are often oversized as a safety precaution against running out of hot water. Tankless units avoid this potential waste with their modulating capabilities.

Other considerations

Specifiers should also consider durability, usability, and lifespan when selecting commercial water-heaters. Typical storage tank units contain:

- a glass lining that can easily be broken during transport or installation; and

- anode rods that can harbour scale formation within the tank. In contrast, certain tankless units come with stainless steel casing and commercial-grade heat exchangers for longer life.

It is here the modular components also come into play. The ability to replace faulty components instead of scrapping the entire unit increases lifespan. Full diagnostics alert owners to errors within the heater, as opposed to storage tank units, which give limited warning of system failures and must usually be replaced in their entirety when a part fails. This speaks to the overall longevity benefits of tankless water-heaters. In commercial applications, tankless units can last almost twice as long as storage tank heaters, based on comparisons of manufacturer warranties.

Of course, this presumes the tankless unit will be properly maintained. One must always consider the application. Consistent use of extremely hot water will hasten scale buildup and essentially mandate more frequent flushing of the tankless unit.

Nonetheless, tankless units are more resistant to scale buildup than tank-type units would be under similar conditions. This is because the absence of stored water helps prevent sediments from accumulating. It is also advised to filter incoming water to maximize quality and reduce the toll on the tankless system. Although this is true for any water-heating system, it is more important for a tankless assembly because it is smaller and, therefore, less clogging is needed to impact performance, relative to a storage tank.

One additional factor to consider is the gas-line requirement for tankless heaters, which may be larger, depending on the size of the temperature rise. One can ensure a proper gas supply by increasing the pipe diameter or gas meter size, as necessary.

Although switching to tankless brings with it many of the benefits mentioned in this article, it is not always a simple process, depending on the application. The gas line, venting, and power must all potentially be reconfigured for a tankless system, thereby increasing the installation cost. Specifiers must consider each application on a case-by-case basis to make the best decision.

Making a crucial decision

There are many factors to consider when selecting a commercial water-heating system. A storage tank might seem like the accepted, most straightforward option. It can be less expensive—at least initially—and likely more familiar. However, it is also important to look beyond the present moment.

Any system needs to meet hot-water demand consistently and without exception. Anything can go wrong in a commercial operation, but hot-water supply must never be compromised in a way that results in costly shutdowns. Tankless water-heaters provide the most reliable, energy-efficient solution; they are generally less expensive over the long run, after energy savings are considered. They are a tested and true option forward-thinking specifiers would be wise to consider.

| COMMERCIAL TANKLESS VS COMMERCIAL TANK |

Commercial tankless:

Commercial tank:

|

Jason Fleming serves as vice-president of sales and marketing for Noritz America. He is a 20-year plumbing industry veteran. Fleming can be reached via e-mail at jfleming@noritz.com.