Styling with fire-rated glass

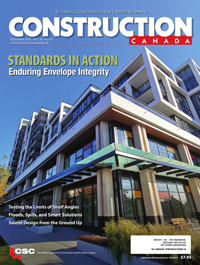

Photo © Carter & Fitzgerald

Fire-protective glass aids in compartmentalization, preventing the spread of flames and smoke from one section of a building to another. It is approved for use in windows, doors, transoms, and sidelites. To achieve this status, fire-protective glass must prove it can remain in frame during intense heat without shattering or slumping out of the opening. It must also demonstrate that, once heated, it can resist the thermal shock of cold water from sprinklers or a fire hose. Failure at either stage could create a breach where the flames, smoke, and toxic gases could travel further throughout the building, jeopardizing life and property.

New fire-protective glass options can satisfy the requirements of the Underwriters Laboratories of Canada (CAN/ULC) S106-15, Standard Method for Fire Tests of Window and Glass Block Assemblies. They are also able to meet CAN/ULC S104-15, Standard Method for Fire Tests of Door Assemblies.

Fire-resistive glass goes a step further, and blocks radiant and conductive heat transfer. This means that it functions the same way, and meets CAN/ULC S101-14, Standard Methods of Fire Endurance Tests of Building Construction and Materials, as a solid barrier wall. It can be specified in floor-to-ceiling sizes as well as in wall-to-wall and horizontal assemblies, thereby expanding design freedom.

To achieve such a high level of fire performance, fire-resistive glass is typically thicker than its fire-protective counterpart. One prominent product is composed of multiple layers of glass sandwiching clear, intumescent interlayers. When heated, the interlayers turn to foam, thereby obscuring vision but preventing heat from passing through the wall. Even if a flame is burning on one side of the glass, the opposite surface would remain cool enough to touch.

This becomes important in areas such as stairwells that require a temperature-rise rating to protect building occupants for the time period they are transiting through the exit. Since structural fires can quickly exceed 871 C (1600 F), maintaining a safe temperature is as important as fire containment.

A better framework

When a glass system undergoes testing to receive its fire rating, it must be evaluated using appropriate glazing materials within a compatible framing system, and all components must meet the same standards. For many years, framing has remained relatively unchanged. The only real choice on the table was bulky, wrap-around hollow metal steel. It did the job, but often did not complement the appearance of the surrounding non-rated framing systems.

Fortunately, the innovation in frames has kept pace with the changes in glass. Architects now have the option of specifying sleek steel frames that are cold-rolled instead of bent. They offer tremendous strength and narrower sightlines and make it possible to have fire-rated curtain walls.

Modern fire-rated frames can be finished to match virtually any colour scheme. They can also be clad in stainless steel or hardwood where desired. The most important consideration is to ensure the glass and framing have been tested as a system and carry identical ratings from an independent laboratory such as Underwriters Laboratories (UL) and ULC.

Having a variety of both fire-protective and fire-resistive options means safety and design can stay a top priority. There is no longer a need to compromise one for the other. In fact, the current levels of performance and esthetic options in fire-rated glass are greater than at any other time in history.

A new and improved ceramics class

One type of glazing material that has changed fire protection is not technically glass, but ceramic. Long known for its ability to tolerate heat, ceramic has been used in everything from cooktops to car engines. Manufacturers created a transparent ceramic that is able to meet fire codes without the use of wires.