Steam shower systems

Images courtesy the Tile Council of North America

Room construction

A steam system’s long-term performance depends directly on the quality of the design and construction of the shower room itself, as well as the components included within.

Ceilings and walls

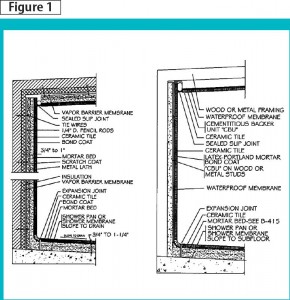

One must consider not only the construction materials in front of the wall (e.g. tile, marble, granite, and acrylic), but also what is behind these surfaces. To keep steam from escaping the room, a waterproof membrane must be constructed around the entire space, sealing not just the walls, but also the ceiling.

Figure 1 show the two options—a vapour-proof membrane using cement mortar, and a waterproof membrane with thin-set. Either is permitted in a commercial steam application as it mainly depends on local preference.

Proper room design also necessitates the ceiling be sloped 160 mm/m (2 in./ft), although the smoother the surface, the smaller the slope needs to be. This is an especially crucial consideration for commercial applications in which the generator is running out all the time. Under such conditions, large amounts of condensation will inevitably form on all surfaces. If the ceiling does not slope to allow the water to run down the wall, the room becomes a ‘rainforest,’ depositing hot droplets on unsuspecting and unappreciative bathers below. Consideration must also be given to seating areas. All benches and other seating locations must be sloped to allow the condensation to run off.

Shower doors

To retain the steam in the space, a gasketed floor-to-ceiling glass door is mandatory. While this door must be sealed on all four of its sides, the showering space needs a small amount of air infiltration—not for performance reasons, but so the room looks like a steam room. Just as a cloud in the sky needs air particles to be seen, a steam room needs air particles to render the steam itself visible to the bathers. Generally, there are enough gaps around the door hinges to create the proper esthetic effect. People moving in and out of the steam room, opening and closing the door, will help as well. However, if clients complain they cannot see the steam, the space needs a little more air.

Images courtesy Mr. Steam

Steam components

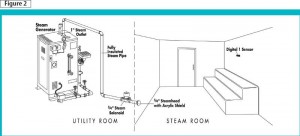

Figure 2 shows a fairly typical commercial installation, with the generator in a location remote from the room. Although it may seem perfectly obvious, the generator itself must be positioned on a solid surface and upright.

As previously noted, the system pipeline to the steam head in the room should extend no more than 15 m (50 ft). The longer the run, the more critical the insulation around the pipe to prevent heat loss. It is almost important to remember this line will be transporting steam, so the insulation must be rated at 100 C (212 F) or above.

The steam head, which delivers steam to the room, should be positioned 152 to 305 mm (6 to 12 in.) above the floor on the opposite wall from where bathers will be standing or sitting. The temperature sensor or probe should be placed on the opposite wall, away from the steam head.

The sensor’s function is to monitor and help maintain the preselected room temperature. Locate the probe too close to the head where it comes in contact with fresh steam, and one will get a false reading that is too hot. A better position is where the bather will sit or stand and at head or shoulder height—the ‘comfort level,’ or usually 1.2 or 1.5 m (4 or 5 ft) above the floor.

Add-ons

Commercial facility management should always retain readily accessible control of the device for setting the steam temperature and managing the various aroma, sound, and even colour therapies incorporated into their systems. The smaller light-commercial applications—such as those found at spas, resorts, and high-end hotels—lend themselves to these add-ons. After all, their clientele tends to want the complete steam experience that, for example, an aroma oil delivery system can provide.

Aromatherapy

This particular add-on is one of the most popular ways to create the right mood in commercial steam rooms. An automatic electronic dispenser, which typically includes a control pump and an oil atomizer, connects directly to the steam line and is controlled either by the user at the shower or, more likely, by management from a remote onsite location. These devices envelop the room with specially made aromatic, essential oils such as the eucalyptus and lavender. Some dispensers can regulate the rate of oil flow to create a better balance within the steam room.

Lighting

Poorly lit steam rooms appear uninviting and may even contribute to traffic problems if visibility is poor. A vapour-proof light can be a beneficial addition, but one should ensure the light is not too bright. After all, steam rooms are supposed to encourage rest and relaxation.

Steam stops

Lastly, many installations also include a steam stop in the shower so the system can be quickly shut down.

Proper maintenance

Aside from improper generator-sizing, the primary problem for any steam installation is sediment buildup. Even if the application draws its water north of the Arctic Circle, once the water is heated, sediment is created.

A commercial system that runs many hours each day is particularly vulnerable. Left unchecked, this sediment leaves a thick coat on the generator element, undermining performance and even risking premature failure. It can also cake up inside the generator tank, displacing the water. In short, removing this sediment quickly and efficiently helps sustain the system’s performance and longevity.

The best way to do this is by flushing the system on a regular basis. Light commercial systems often employ an automatic flushing system after each use to remove any impurities from the generator and its tank, while providing the next bather with fresh water for steam.

Larger, heavy-duty commercial systems employ a similar and equally essential device—an automatic blowdown drain kit that can be programmed to flush the entire system at preset intervals, such as when the unit is shut down overnight. Certain municipalities require the blowdown discharge to be 60 C (140 F) or less. Under such circumstances, a companion blowdown tank that conforms to Section VIII of BPVC, “Pressure Vessels,” is used to cool the hot water until it reaches the permissible temperature.

Even with these automatic flushing devices, a highly active commercial steam system demands a regular maintenance schedule. Frequency depends on use, and every generator manufacturer has a set of recommendations to be followed to keep its tank free of sediment. However, a thorough inspection and cleaning of the system every 30 days is highly recommended in hard water areas (at least every 90 days in soft water locales). The pipes leading to the blowdown drain should also be checked regularly for sediment buildup.

Attention to fundamentals

As commercial and institutional facilities and their patrons become increasingly aware of the powerful health benefits of steam therapy, demand for these systems will only grow. Creating a high-performance commercial steam system—including one that incorporates aromatherapy and other user-friendly enhancements—need not be an especially complicated or difficult affair.

However, to ensure success, one must pay close attention to numerous essentials—most notably, proper generator-sizing as well as regular care and maintenance of the system. Faithful adherence to these fundamentals will enable clients to build first-rate steam therapy systems that will perform reliably and at a high level for many years.

Bart Gorelik is the regional sales manager for Mr. Steam, headquartered in Long Island, N.Y. A 36-year veteran of the plumbing and heating industry, he joined Mr. Steam in 2008 after more than three decades as an independent manufacturers representative. Gorelik is a member of the Decorative Plumbing and Hardware Association (DPHA) and a registered trainer for continuing education unit (CEU) courses for both the American Institute of Architects (AIA) and the Interior Design Continuing Education Council (IDCEC). He can be reached via e-mail at bgorelik@sussmancorp.com.