Sprung instant structures and the fight against COVID-19

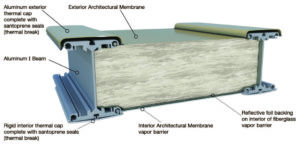

Structures are considered single-storey buildings or buildings with any height, as defined by the National Building Code of Canada (NBC). The temporary facilities erected at the hospitals were a “frame-supported structure—a structure consisting of a pre-stressed membrane cover that achieves and maintains its shape, strength, and stability through, and is supported by, an independent frame” as defined in Canadian Standards Association (CAN/CSA) S367-12, Air-, cable-, and frame-supported membrane structures. The structure consists of tensioned membrane materials (acrylic-coated polyvinyl chloride [PVC] fabric) interconnected and supported on a structural aluminum frame. They have been designed for ease of erection and dismantling, but require complex analysis and design.

The erected structures meet the requirements of CSA S367-12 and CSA S157, Strength Design in Aluminum, for environmental loads for wind, snow, and seismic criteria, as set out by a local authority. The wind forces on the structures are identified using wind tunnel experiments because of the unique shape and behaviour of the structure. The figures used in NBC’s structural commentaries require the designed building to have roof diaphragms. The values in Figure I-7 (CpCg) of the 2010 NBC Structural Commentaries (Part 4 of Division B are not appropriate for the design of structures without diaphragms, such as tension membrane structures and buildings using cabling for lateral support. The CpCg values from Figure I-7 were developed based on the building moving as a rigid body.

The membrane is considered non-rated or combustible; the aluminum frame does not burn and can be categorized as non-combustible. Third-party testing has confirmed the membrane has a flame spread of 25 or less and a smoked developed index of 450 or less. The membranes have been tested to Underwriters Laboratories of Canada (CAN/ULC) S109, Standard Method for Flame Tests of Flame Resistant Fabrics and Films, and CAN/ULC S102, Standard Method of Test for Surface Burning Characteristics of Building Materials and Assemblies, as outlined in (NBC, the 2019 Alberta Building Code, the 2012 Ontario Building Code, and CSA S367-12. The membrane also meets the requirements of National Fire Protection Association (NFPA) 701, Standard Methods of Fire Tests for Flame Propagation of Textiles and Films, and ASTM E84, Standard Test Method for Surface Burning Characteristics of Building Materials.

From a building envelope viewpoint, the membranes have water vapour permeance between 21 to 38 ng/(Pa·s·m2), and the membranes are designed to be strong enough to resist wind pressures.

The exterior membrane and liner are always kept in tension and are attached/integrated into the arches by a compression connection. The envelope assembly shown in Figure 5 forms a continuous and tight barrier.

In 2010, full building testing of a similar structure was completed in the United Kingdom. The testing followed the English standard BS EN 13829:2001, Thermal performance of buildings. Determination of air permeability of buildings. Fan pressurization method, and showed air leakage (air permeance) of less than 2.01m3/h.m2 (0.56 l/m2sec). Improvements on the air leakage has been made since the testing was done.

The insulated envelope assembly not only provides an excellent environment barrier, but it is robust. The assembly has been tested and accepted by the Miami-Dade County, Florida, Product Control division, as complying with the requirements of the High Velocity Hurricane Zone (HVHZ) of the Florida Building Code.

Project delivery method

The four projects were completed using multiple project delivery methods. The projects in Ontario were completed using a design/build delivery model, a construction management method, and a hybrid between design-build delivery and construction management using CCDC-2 as the contract form. The project in Calgary was completed using a construction management model with the foundation design as a delegated design. Due to the speed and uniqueness of the projects, no formal project manuals were produced. However, the structural work completed on the projects could have been covered using performance specifications in the following sections:

- 13 34 00—Fabricated Engineered Structures in combination with 13 31 23—Tensioned Fabric Structures, or 13 31 33—Framed Fabric Structures;

- 05 14 00—Structural Aluminum Framing; and

- 05 16 00—Structural Cabling.

Project challenges

Not surprisingly, even with proven materials and design methods, projects in two provinces in the midst of a pandemic, while responding to unique design and construction needs, presented some challenges.

While the materials could be fabricated and shipped easily within Calgary, the same was not true for the Ontario facilities. With air traffic halted, the Ontario materials and personnel were trucked across country. All consultations were handled through a variety of phone calls and video conferencing, with a local engineering firm working with KTA Structural Engineers on the Ontario site inspections.

With the Calgary structure, the challenges were to accommodate the 900-mm difference in the slopes of the parking lot. A daily challenge was the need to use alternative materials and construction methods. As there are utilities under the parking lot, anchorage had to be shallow to prevent the piercing of the fibre-optic network.

During construction, infection control had to be observed. Social distancing does not work well on a construction site. CANA adjusted its usual work habits by working 24/7 with workers coming on for 12-hour, staggered shifts to reduce the number of people onsite at any one time. Specific personal protective equipment (PPE) was available for all personnel, including N95 face masks and gloves in addition to regular construction safety equipment. Not only did workers have to have the requisite knowledge, skills, experiences, and tickets, they also had to be trained in infection control/safety protocols.

Weather during construction was not always compliant, and all sites had to deal with rain, wind, snow, and sub-zero temperatures which would normally cause delays, but not in the case of these projects.

Post-COVID-19 use

When the COVID-19 crisis has crested and the temporary facilities are no longer necessary, they can be sanitized, dismantled, stored, and reused. All major components of the facility can be reused, including the aluminum members, the membranes (which were stressed only to a certain level so they could be reused), the adjustable flooring, and the lights and mechanical units. The modular partitions can also be repurposed. The only components that cannot be reused are the bolts.

Conclusion

COVID-19 has presented unique challenges and opportunities. These temporary facilities demonstrate the construction industry can rise to the occasion. With the will and co-operation of all parties, rapid design, fabrication, and construction are possible. Temporary facilities, in time of crisis, can be constructed in weeks rather than years.

David Thompson is a principal at KTA Structural Engineers Ltd of Calgary, Alta. He has been a professional engineer for more than 35 years with over 25 years of experience in the design of tension membrane structures in 55 countries. He was a member of the Canadian Standards Association (CSA) committee for CAN/CSA S157, Strength Design in Aluminum/Commentary on CSA S157-05, Strength Design in Aluminum Design of Aluminum Structures, and he serves as a member of ASCE Standard Committee for ACSE-55 Tension Membrane Structures. Thompson has been a member of CSC since 1990 during which he served on the Canadian Construction Documents Committee for 10 years representing the Association of Consulting Engineering Companies. He can be reached at dpt@kta-eng.com.

David Thompson is a principal at KTA Structural Engineers Ltd of Calgary, Alta. He has been a professional engineer for more than 35 years with over 25 years of experience in the design of tension membrane structures in 55 countries. He was a member of the Canadian Standards Association (CSA) committee for CAN/CSA S157, Strength Design in Aluminum/Commentary on CSA S157-05, Strength Design in Aluminum Design of Aluminum Structures, and he serves as a member of ASCE Standard Committee for ACSE-55 Tension Membrane Structures. Thompson has been a member of CSC since 1990 during which he served on the Canadian Construction Documents Committee for 10 years representing the Association of Consulting Engineering Companies. He can be reached at dpt@kta-eng.com.