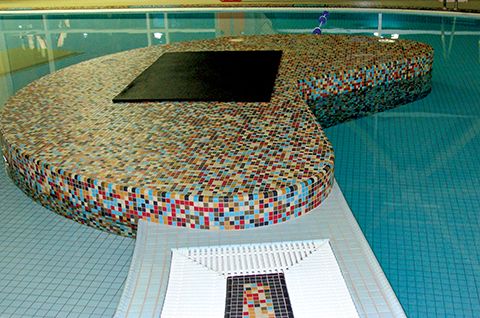

Specifying tiles outside the building

The installation team must understand the unique mortar coverage requirements of exterior installations. These outdoor applications require 95 per cent coverage—this requirement increases to 100 per cent with natural stone. Substrate variation, bonding material, trowel selection, and trowelling technique are critical factors to consider when trying to achieve proper coverage. If voids of mortar beneath the tile exceed the industry requirement, they can accumulate moisture. In freeze/thaw climates, this water can freeze and expand, causing degradation and bond failure of the thin-set.

To achieve the required coverage, TTMAC recommends setting the tile on freshly notched thin-set mortar, and sliding it back and forth perpendicular to the notches. Back-buttering can also be used to meet coverage requirements. This involves applying a thin coat or mortar to the back side of the tile with the flat side of the trowel immediately before setting.

The dot method should never be used with cement-based mortars for wall applications. With this method, the installer puts globs, or dots, of mortar on the back of the tile, rather than carefully trowelling it. Although it may seem like it saves time and reduces material expenditures, the resulting voids in coverage leave tile susceptible to moisture trapping, which can cause debonding or compromise the bond.

Even the most carefully installed exterior projects may suffer from lippage—a condition occurring when tiles are not laid to a uniform level, so one edge or corner of a tile is higher than the edges or corners of an adjacent tile. Some degree of lippage is normal for exterior installations. However, lighting conditions can significantly worsen its appearance. Light shining on exterior installations at a flat angle, parallel to the surface, can accentuate normal and acceptable inconsistencies. Having temporary lighting that mimics the planned lighting scheme, or awareness of these overly exposed areas, helps ensure the lighting and tiled installation work together.

Conclusion

Selecting and effectively using high-quality products for exterior projects in Canada requires careful consideration of various factors. No two exterior projects are exactly the same, but a comprehensive understanding of the conditions that should drive product selection will always contribute to more successful installations. Ensuring the material qualities are not only rated for exterior use, but also work together as a system, pays off in the creation of a beautiful and durable installation.

Tom Plaskota, CDT, serves as technical support manager for H.B. Fuller Construction Products, and is responsible for managing the field support team that develops and communicates technical information and provides technical service. He has been working with the TEC brand of surface preparation and installation systems for flooring, ceramic tile, and natural stone since 1997. Plaskota is actively involved with the National Tile Contractors Association (NTCA) and is a former industry director for the Chicago CSI Chapter. He has more than 30 years of experience with construction methods, testing, and materials. Plaskota can be reached at tom.plaskota@hbfuller.com.

Tom Plaskota, CDT, serves as technical support manager for H.B. Fuller Construction Products, and is responsible for managing the field support team that develops and communicates technical information and provides technical service. He has been working with the TEC brand of surface preparation and installation systems for flooring, ceramic tile, and natural stone since 1997. Plaskota is actively involved with the National Tile Contractors Association (NTCA) and is a former industry director for the Chicago CSI Chapter. He has more than 30 years of experience with construction methods, testing, and materials. Plaskota can be reached at tom.plaskota@hbfuller.com.