Specifying the four roles of acoustic ceilings

Key takeaways: Isolation from floors above

Adding an acoustic ceiling below a floor slab increases the assembly STC rating approximately six points. This improvement is substantial because without it, the floor slab would need to be more massive to reach the STC 50 minimum, and the resulting impact on the building structure and foundation could be costly for the project. Instead, a moderate weight concrete floor slab with an acoustic ceiling below can meet the STC 50 minimum requirements in building standards. Most importantly, the material type, weight, and CAC rating of the ceiling does not have a significant effect on the overall assembly STC rating. Specifiers can omit CAC rating from the specification and be confident the slight difference in the panel weight (typically less the 2.44 kg/m2 or 0.5 psf) is not substantial enough to affect the STC rating of the assembly. Caution should be taken if the floor or ceiling panels are significantly lower in weight than those used in the author’s 2021 study.

Role four: Achieve background noise levels

Designing a building and its systems to achieve acceptable background noise levels inside rooms is important and required by most building standards.5 If background sound is too loud, it interferes with speech intelligibility and causes stress and discomfort. If it is too quiet, every little noise can be disruptive and privacy suffers. Once noise is inside a room, its negative impact can be lessened by a high NRC ceiling system. Instead of reflecting off all the room surfaces repeatedly, amplifying itself, much of the energy is absorbed by the acoustic ceiling. Beyond this general benefit, acoustic ceilings are typically the only attenuation device between a noisy piece of mechanical equipment in the plenum and people in the room below.

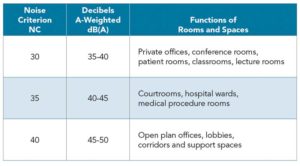

Noisy mechanical equipment should be located away from sound sensitive rooms. Placing a fan-powered box over a corridor is better than positioning it directly over the students inside a classroom. There are situations though when placing noisy equipment over a sound-sensitive room is unavoidable. When this is the case, a simple and straightforward method of ensuring the suspended acoustic ceiling has the capability of attenuating the plenum noise is laid out in the Air-Conditioning Heating and Refrigeration Institute’s (AHRI) Standard 885 (2008), Procedure for Estimating Occupied Space Sound Levels in the Application of Air Terminals and Air Outlets8 as well as in the ASHRAE Handbook HVAC Applications (2023).9 Begin by selecting the appropriate background sound level for each room. Figure 7 provides example background sound levels for many room types in two formats; noise criterion (NC) ratings and A-weighted decibels (dBA) from the ASHRAE Handbook.

Next, the amount of attenuation an acoustic ceiling system can provide needs to be considered. Some building professionals may not be aware of the mechanical noise attenuation prediction method defined in the ASHRAE Handbook and AHRI standard. Many have instead strayed toward a rule-of-thumb based on ceiling panel material type, such as mineral fibre; a certain minimum weight, such as 4.88 kg/m2 (1.0 psf); or a certain sound isolation metric, such as a minimum CAC rating of 35. None of these are correct, and to understand why, one must first understand how acoustic ceilings attenuate plenum noise.

Based on ASHRAE research,11 an acoustic ceiling attenuates the noise of mechanical equipment based on three factors: high absorption (NRC) limits noise inside the plenum and inside the room, a malleable panel surface seals noise leaks where the ceiling panels rest on the metal grid flanges, and moderate panel weight limits the sound passing straight through the panel. The key ASHRAE finding is that most standard ceiling panels available in the market perform the same in the frequencies of concern (500 Hertz octave band and below). Some panels have more weight, but they do not provide as much absorption. Other panels are softer and seal leaks along the grid better, but allow more sound to pass through. When studied empirically, researchers found the various ceiling panels performed within one to four dB of each other. A difference of three dB is barely perceptible. An important outcome of this research is that no metric such as NRC, CAC, or STC is required to characterize the performance of different ceiling panels because they perform so similarly.

An article titled “Specifying Ceilings and HVAC Equipment to Meet Acoustic Requirements” discusses the original ASHRAE research and how the findings were used to develop the industry-consensus prediction method.12