Specifying formaldehyde-absorbing wallboard

By Douglas C. Gehring, PE, CSI, and Stanley D. Gatland II

Last spring, several members of Group2 Architecture Interior Design, revisited their plans for an office space in Edmonton after hearing a wallboard that absorbs one of the highest concentrations of volatile organic compounds (VOCs)—formaldehyde.

The firm’s new lease was for a 478-m2 (5150-sf) top floor plate in a nine-storey building. They were to completely remodel the space, adding new framework and drywall, among other things. When this type of gypsum product was discovered, they wanted to learn more to determine whether it was a suitable choice for the space.

According to Gareth Leach, senior architectural technologist and associate with Group2, there are numerous staff members who had personal concerns with indoor air quality (IAQ). Being aware of these concerns, the firm wanted to accommodate them as much as possible.

IAQ concerns

The Group2 team was well aware of the health concerns linked to carcinogens in construction, which made the VOC-absorbing material of interest. It is not just paint that contains VOCs, but also lacquers, paint-strippers, solvents, adhesives, and glue. Additionally, carpeting, flooring, furnishings, cabinets, and shelving can offgas VOCs. Plywood, particleboard, and urea formaldehyde foam insulation are also known sources.

While rampant in construction and renovation materials, there are also everyday items that reintroduce VOCs into the environment long after a construction project has wrapped up. These can include cleaning materials and pesticides, perfumes and hairsprays, wrinkle-free and waterproofed fabrics, smoke from candles and tobacco, and office equipment. It is nearly impossible to escape these pervasive indoor toxins.

When VOCs and other air pollutants persist, healthy air does not. In fact, indoor air pollution is one of the greatest risks to human health according to the World Health Organization (WHO). Further, Health Canada reports poor IAQ increases the severity and frequency of respiratory symptoms experienced by asthmatics. Indoor air pollution has also been linked to headaches, fatigue, and allergies.

Clearly, IAQ impacts the health and comfort of a building’s occupants, for better or worse. Group2 wanted to make sure its indoor environment fell into the ‘better’ category for its new Edmonton office space.

Leach explained that if Group2 could make its staff happier through healthy design, the firm had a responsibility to implement measures which help achieve this. As a result, they specified the new VOC-absorbing gypsum wallboard—– which will continue to effectively clean air even when finished and painted with most water-based acrylic and epoxy paints up to 25 coats, or covered with breathable wallpaper using conventional gypsum board techniques—among other low-emitting products for the project in an effort to create a more comfortable and sustainable environment.

Healthy IAQ for healthier occupants

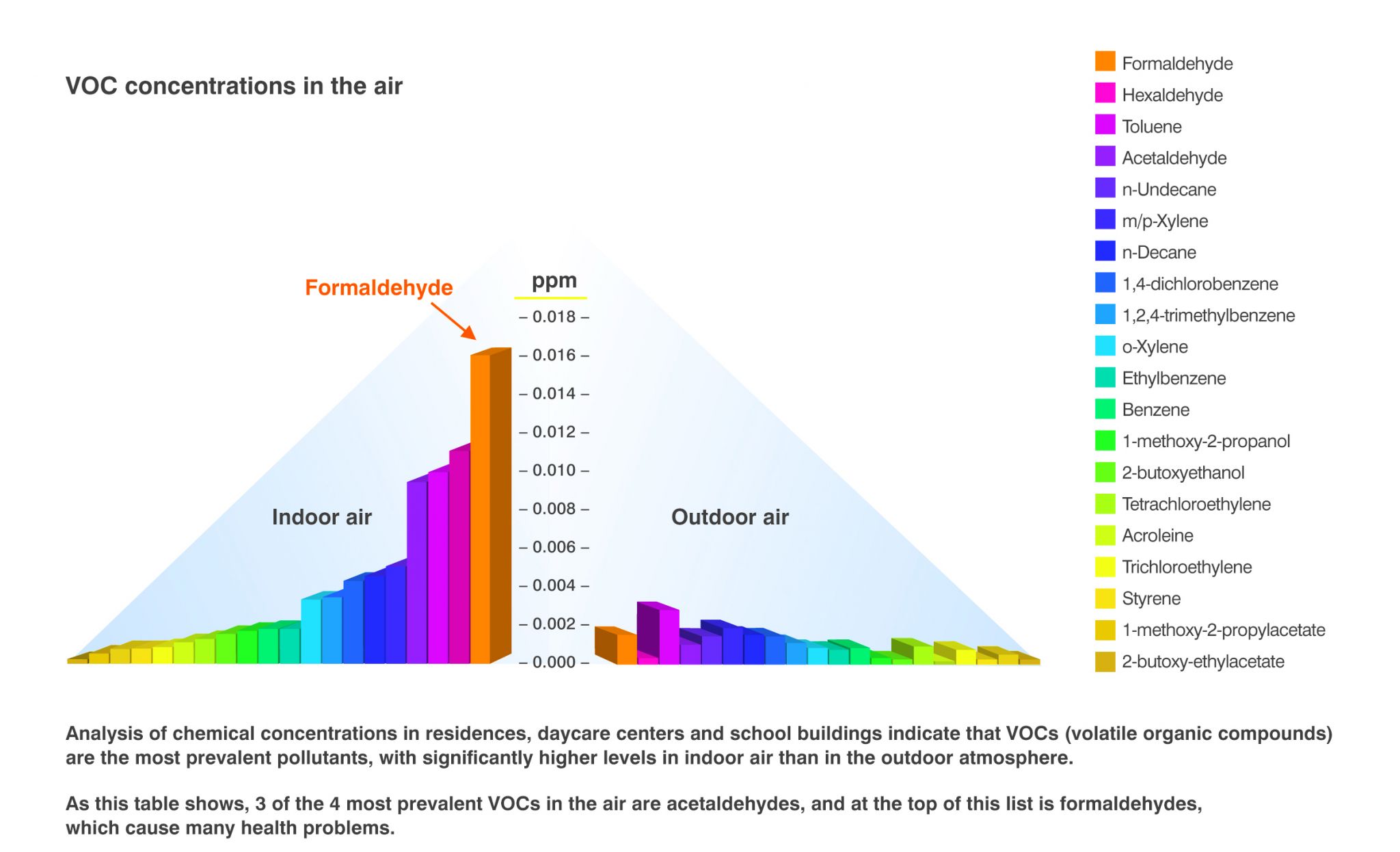

The pursuit for healthy IAQ is a result of the heightened demand for well-insulated buildings, which first made headlines in the 1970s. As building envelopes tightened, so did the flow of air into and out of buildings. This has been good news for thermal comfort, but not for indoor air. Clearly, a tightly sealed building traps indoor toxins inside, which also happens to be where people spend 90 per cent of their time, according to Health Canada. Unfortunately, pollution levels can be 100 times higher indoors than outdoors.

Therefore, it is no surprise IAQ has become a significant component of the sustainable design movement, and continues to gain traction year after year. By focusing on improving the health of indoor air, architects and design professionals can help enhance the comfort of building occupants.

It is important to also understand VOCs are just one source of indoor air pollution. There are numerous offenders, including moisture, mould, some plants and insects, viruses, and bacteria. There are also harmful particulates from:

- smoke;

- outdoor air and cleaning;

- inadequate air circulation and ventilation;

- carbon monoxide (CO) from auto exhaust and tobacco; and

- CO from occupants and combustion appliances.

A healthy building addresses each of these issues, as well as VOCs emitted as gas inside the building. When the concentration of VOCs is high enough, it can be carcinogenic to humans.

VOCs are carbon-based chemicals that easily evaporate at room temperature. These invisible and mostly odourless toxins can cause short- and long-term adverse health effects, depending on the type, amount, and length of time for which someone is exposed. Health effects can include eye, nose, and throat irritation, headaches, nausea, and even nerve problems. There may be hundreds of individual VOCs inside buildings, but formaldehyde is the most common and best-known indoor air pollutant. Colourless, flammable, and highly reactive at room temperature, its concentrations vary daily and seasonally.

Reducing VOCs, improving IAQ

Once the negative impacts of VOCs and poor IAQ are understood, the question is no longer ‘should’ indoor air be affected, but ‘how’ can it be. Fortunately, many remediation strategies are at architects’ disposal if they prioritize healthy IAQ during design. Supplying outdoor air ventilation to help dilute gaseous indoor pollution sources is one way, and using filtration to remove airborne particulates is another. Further remediation strategies include:

- controlling indoor humidity through dehumidification;

- managing moisture flow through the building envelope;

- controlling building air leakage; and

- removing or reducing pollution sources by specifying low-emitting materials.

Such materials can be certified using performance-based standards for chemical and particle emissions, like those through Green Seal, GreenGuard, and SCS Global Services programs. Specifying these products can also help projects vying for Leadership in Energy and Environmental Design (LEED) credits.

Within the LEED programs, these products can contribute to credit in multiple categories including:

- Materials and Resources (MR) Credit 4.2, Recycled Content;

- MR Credit 5, Regional Materials (depending on location);

- Indoor Environmental Quality (EQ) Credit 3.2, IAQ Plan–Before Occupancy;

- EQ Credit 4, Low-emitting Materials; and

- EQ Credit 10, Mould Prevention (Schools).

Beyond the VOC-absorbing properties featured in the wallboard used in the Group2 office space renovation, the product is also easily recycled in the same way as regular gypsum board, among other environmentally sound attributes.

Regardless, Group2 was concerned with creating a healthy place in which its employees could thrive. This is why they opted to include VOC-absorbing gypsum wallboard to their arsenal of IAQ tools for the project.

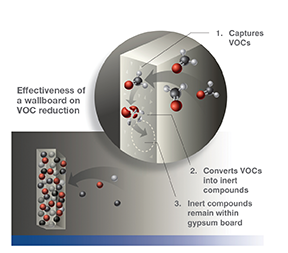

This high-tech material helps eliminate formaldehyde from the air through chemical adsorption, which results when the wallboard attracts gas molecules to the surface and they migrate into the core. There, a bond-forming chemical reaction is created between formaldehyde gas and the formaldehyde scavenger, and the contaminant molecule is converted into an inert compound, which remains within the gypsum core. The technology is relatively new, but proven for interior wall and ceiling applications.

Assessing the material’s VOC absorption

Wallboard products claiming to capture and permanently remove VOCs—such as formaldehyde and other aldehydes present in the indoor environment—are tested in accordance with International Organization for Standardization (ISO) 16000-23, Indoor Air–Part 23: Performance Test for Evaluating the Reduction of Formaldehyde Concentrations by Sorptive Building Materials. This is the indoor air performance test for evaluating the reduction of formaldehyde concentrations by absorptive building materials. The product Group2 used was validated by third-party tests conducted by UL Environment, under AQS Test Report No. 17284-03, which measured the wallboard’s permanent formaldehyde absorption capacity of 0.4 g/m2.

UL Environment is a global independent safety science company that works to advance global sustainability and environmental health. The wallboard used in the Group2’s Edmonton offices was UL-validated, meaning it was proven to perform as it claimed it would.

According to ISO 16000-23, the laboratory test method applies to wallboard among other materials like wallpaper, carpet, and paint products. While the pollutant’s absorption can occur through adsorption, absorption, or chemisorption, the material’s performance with respect to its ability to reduce the concentration of formaldehyde in indoor air is evaluated by measuring sorption flux and saturation mass per area. Essentially, products adhering to ISO 16000-23 must show formaldehyde concentration reduction at a point in time and display its ability to maintain that performance.

The test occurs within an air chamber with a continuous flow of formaldehyde-spiked air. The wallboard Group2 specified for its offices, for instance, was introduced to an air chamber that had a 100 ppb (parts per billion) concentration of formaldehyde. On entering the chamber, the gypsum board cut the concentration of the toxin by more than half. On day seven, the formaldehyde injection was terminated and the airflow within the testing space remained formaldehyde-free for the remainder of the 28-day testing period. This indicated the formaldehyde absorption of the wallboard is permanent with no re-release.

Conclusion

The tests for VOC-absorbing wallboard are compelling and lend a hand to the architectural community’s efforts to build healthy structures. Employing the VOC-absorbing gypsum wallboard at Group2’s office has provided the employees with peace of mind, explained Leach. The perceived impact is the odours associated with construction-generated VOCs were lower than expected.

Douglas C. Gehring, PE, CSI, LEED Green Associate, is the director of marketing technical services for CertainTeed Gypsum. In this role, he is active in technical development and support of new and existing gypsum products and systems. Gehring is a member of ASTM and serves on four of its committees, he is also a member of the American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE), American Society of Mechanical Engineers (ASME), and National Fire Protection Association (NFPA). He holds a bachelor of science in mechanical engineering from the University of South Florida, and is a professional engineer in the state of Florida. Gehring can be reached by e-mail at doug.gehring@saint-gobain.com.

Douglas C. Gehring, PE, CSI, LEED Green Associate, is the director of marketing technical services for CertainTeed Gypsum. In this role, he is active in technical development and support of new and existing gypsum products and systems. Gehring is a member of ASTM and serves on four of its committees, he is also a member of the American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE), American Society of Mechanical Engineers (ASME), and National Fire Protection Association (NFPA). He holds a bachelor of science in mechanical engineering from the University of South Florida, and is a professional engineer in the state of Florida. Gehring can be reached by e-mail at doug.gehring@saint-gobain.com.

Stanley D. Gatland II is the manager of building science technology for CertainTeed Corporation. In this role, he is responsible for generating and providing technical information to architects, engineers, and building scientists on the system performance of new and existing building envelope materials, as well as building science educational training. Gatland has more than 20 years of experience and expertise in the areas of building science and architectural acoustics. Gatland is a graduate of the University of Massachusetts, Amherst, with both a master of science degree and bachelor of science degree in mechanical engineering. He can be reached at stanley.d.gatland@saint-gobain.com.

Stanley D. Gatland II is the manager of building science technology for CertainTeed Corporation. In this role, he is responsible for generating and providing technical information to architects, engineers, and building scientists on the system performance of new and existing building envelope materials, as well as building science educational training. Gatland has more than 20 years of experience and expertise in the areas of building science and architectural acoustics. Gatland is a graduate of the University of Massachusetts, Amherst, with both a master of science degree and bachelor of science degree in mechanical engineering. He can be reached at stanley.d.gatland@saint-gobain.com.