Specifying EPS as geofoam

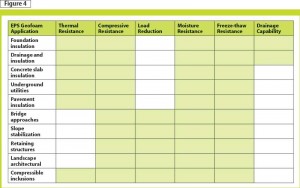

EPS insulation applied over dampproofing or waterproofing coatings on foundation walls protects them from damage. Select foundation insulation products can provide a monolithic insulation layer to eliminate thermal shorts and reduce thermal stresses that can cause cracking of concrete walls. Additionally, the EPS’ smooth surface, in contact with the soil, acts as a capillary-breaking layer to direct water to the drainage tile. At the same time, the grooved surface, in contact with the foundation wall, also provides an additional drainage plane to relieve any hydrostatic pressure that may develop adjacent to the foundation wall and also direct water to the drainage tile.

Concrete slab insulation

Heat loss through an uninsulated concrete slab can be a significant source of energy loss. When applied below the concrete slab as part of new construction, EPS offers a monolithic insulation layer that reduces heat loss and results in a uniform floor surface temperature that can be maintained at the interior room temperature.

Another application for concrete slab insulation becoming more common in energy-efficient residential and commercial construction is use as a component in radiant floor heating systems. In this application, hydronic tubing is cast into the concrete slab and EPS insulation is installed beneath the concrete slab to ensure heat is distributed uniformly throughout the entire floor area.

EPS insulation is also commonly used as a load-bearing component in residential, commercial, and industrial floor systems. Once design loads have been determined, the most cost-effective type of EPS insulation for use as sub-slab insulation can be selected.

Underground utilities

Utility lines are usually placed below the level where frost penetration into the soil is expected to prevent water freezing in the lines. However, high water tables, rocky outcrops, or soil conditions can make it impossible to bury lines deep enough. Under these conditions, the utility line can be insulated with EPS at the time of installation to increase the duration the pipe can store still water before freezing.

It is also feasible to reduce stresses on large flexible culverts by placing EPS geofoam as a lightweight fill material above a culvert. In this application, a portion of the fill material above the culvert is replaced with geofoam. The product can significantly reduce loads on buried utility lines because it is up to 50 times lighter than other traditional fills with similar compressive resistance properties.

Road insulation

Highway pavement designs may be governed by subgrade stress and deformation criteria or frost heave protection requirements. Where the pavement thickness is controlled by frost heave conditions, considerable savings can be realized by installing EPS geofoam to insulate the pavement structure. In this application, high-density material is used to provide the required R-value, compressive resistance to carry high design load, and long-term moisture resistance.

When geofoam is used as a subgrade insulation element, care must be exercised to address differential icing between insulated and uninsulated portions of the roadway. One method of controlling differential icing is by varying the thickness of the pavement structure above the insulation.

Road embankments or bridge approaches

Another common application for EPS geofoam is as a structural lightweight fill material to construct road embankments or bridge approaches. When roads must be constructed over subsoils with low load-bearing capacity or soils with unacceptably high settlement characteristics, EPS can be used to replace traditional aggregate fill materials; this reduces the settlement and the load on the subsoil.

Other poor soil conditions exist at rivers or muskegs where the bridge structure may be supported on a pile foundation. In this type of construction, bridge approaches are constructed using EPS geofoam.

Slope stabilization

When side-slope failure occurs in road applications, it is often the result of subsurface soil with low load-bearing capabilities. EPS is used to improve the balance of driving and resisting forces along a potential failure surface. Improvement in slope safety factor against failure can be achieved by soil excavation and replacement with geofoam in the driving block.

The back slope of the excavation is sloped to be self-supporting. EPS lightweight fill material has a density of about one to two per cent of soil or rock, but it has sufficient strength to support typical loads encountered in highway construction applications.

Retaining wall or abutment

EPS geofoam lightweight fill material can be used as part of the design solution for retaining wall or abutment applications. The basic concept is to place geofoam block in a wedge-shaped configuration with the natural or built-up soil behind the retaining wall shaped at a sufficient angle of repose so it is self-supporting.

Since EPS density is low relative to standard aggregate backfill materials, vertical stresses that develop behind a retaining wall or abutment are much lower. When vertical (axial) load is applied to materials, they usually expand laterally (transversely) in the other two directions perpendicular to the axial compression. Poisson’s ratio is the ratio of the percent change (strain) in the horizontal dimension, divided by percent change in the vertical dimension for a material being compressed.

Lateral forces exerted by EPS geofoam are minimal because its Poisson’s ratio within the elastic stress range is approximately 0.1, which is significantly less than the Poisson’s ratio for soil. The light weight of EPS geofoam also results in reduced vertical stresses. As well, the tendency of the interlocked block to settle with a slight tilt away from the wall face reduces the potential lateral load on a wall. The material’s low mass and relatively high compressibility may also offer an additional advantage by limiting horizontal forces against retaining structures. The transition zone between the geofoam and soil should be free draining. Adequate subsoil drainage must be provided to prevent development of hydrostatic pressure and buoyancy.

Additionally, the insulating properties of EPS geofoam reduce the effects of lateral earth pressure resulting from freezing air temperatures. The material’s thermal insulation properties prevent freezing and expansion of the soil behind the retaining wall, as well as protect the retaining wall drainage system.

Compressible inclusions

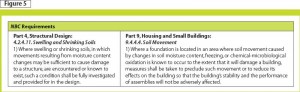

Where swelling or shrinking soils are known to be present, the 2010 National Building Code of Canada (NBC) requires structures to be designed to prevent damage by soil movement. Figure 5 provides the applicable code requirements.

EPS geofoam can be designed as a compressible inclusion between swelling soils and structural elements. Where long-term soil movement can be predicted, compressible EPS inclusions are designed to reduce the forces that would be induced on structures by soil movement, reducing the likelihood of damage to the structure above. The compressible fill material properties are neither affected by the presence of water in the short term nor dependent on the presence of moisture in the long term.

Conclusion

Expanded polystyrene’s versatile performance properties make it suitable for use in various geotechnical applications beyond its long-term service as an insulation material. In addition to its function as an insulation material that provides constant long-term thermal resistance, the range of products available also allow EPS geofoam to offer design properties for building applications from use as compressible inclusions for protecting structural elements to use as an insulation material for supporting structural elements. In other geotechnical applications, EPS geofoam can be employed as lightweight fill material to reduce loads on subsoils or structures or as a structural material to support road construction.

W. James Whalen, P.Eng., MSCE, CSC, is the technical marketing manager for Plasti-Fab Ltd. He is a registered professional engineer and a member of the Canadian Society for Civil Engineering (CSCE). Whalen is also a long-time member of Construction Specifications Canada (CSC) and the Construction Specifications Institute (CSI). With almost 20 years of experience in the expanded polystyrene (EPS) industry, he chairs the Technical Committee at the EPS Molders Association (EPSMA) and is an active member on various industry standards organization committees, including Underwriters’ Laboratories of Canada (ULC) and ASTM International. He can be contacted at jwhalen@plastifab.com.