Specifying EPS as geofoam

In August 2008, the EPS Molders Association (EPSMA) requested independent third-party testing to evaluate the field performance of ASTM C 578 Type I EPS insulation and Type X extruded polystyrene (XPS) insulation installed side-by-side on a below-grade foundation application. (The EPSMA technical bulletin is no. 103, “15-Year In-Situ Research Shows EPS Outperforms XPS in R-value Retention.” To read the document, visit www.epsmolders.org/PDF_FILES/EPS%20Below%20Grade103.pdf). EPSMA published a technical bulletin highlighting results from the test program for each insulation type removed after 15 years of service on the exterior of a commercial building in St. Paul, Minn., at a depth of approximately 1.9 m (6 ft) below grade. In this side-by side installation, the EPS insulation moisture content (MC) was about 25 per cent of the XPS insulation moisture content at the time samples were removed. Consequently, the EPS insulation retained a higher proportion of its R-value at 94 per cent of the specified R-value.

Another method of comparing moisture performance of different foam plastic insulation exposed to high humidity or moist environments is equilibrium moisture content (EMC). A material’s EMC is the moisture content at which the material is neither gaining nor losing moisture when exposed to a specific relative humidity (RH) and temperature. Although it is a dynamic equilibrium, after the moisture content of EPS has reached its equilibrium value under given conditions, EMC changes that take place as conditions change would not exceed 0.15 per cent of the material’s mass. This EPS material property is another reason why actual moisture content measured from field applications differs greatly from results obtained in laboratory tests that expose test specimens to conditions not experienced in actual product applications.

Freeze-thaw resistance

One laboratory test method historically used to characterize freeze-thaw durability of foam plastic insulation is a version of ASTM C 666, Test Method for Resistance of Concrete to Rapid Freezing and Thawing. The procedure was modified to subject insulation samples to up to 600 cycles of full-thickness freezing in air, and thawing by complete submersion in water.

This test procedure has not been correlated to conditions encountered with typical application for an insulation product. It is used to establish how many freeze-thaw cycles are required to create a ‘failure’ of a product, rather than the insulation’s durability in an actual in-situ application.

A review of the performance of foam plastic insulations in below-grade applications by the University of Minnesota Underground Space Centre concluded freeze-thaw testing—involving hundreds of full-thickness freeze-thaw cycles of a fully or partially submerged insulation—is poorly related to the expected performance of insulation for below-grade applications over a building’s reasonable economic life. (The October 1986 report is entitled, “Moisture Absorption and its Effect on the Thermal Properties of EPS Insulation for Foundation Applications: A Review Analysis of Published Laboratory and Field Tests.”) The report also showed the impact of freeze-thaw cycling in a drained, below-grade building foundation application should not be large since the annual number of freeze-thaw cycles is small below grade, and little of the insulation thickness experiences sub-freezing temperatures.

To address the lack of correlation between laboratory test methods and known product performance, the Canadian EPS industry conducted a research project in co-operation with the National Research Council of Canada/Institute for Research in Construction (NRC-IRC) to evaluate the durability of EPS insulation installed in an exterior below-grade application as part of the Exterior Insulation Basement Systems (EIBS) project. (See N. Normandin et al’s “In-situ Performance Evaluation of Exterior Insulation Basement Systems (EIBS)–EPS Specimens” (National Research Council of Canada [NRC] Report No. 3132.1, 1999) and Swinton et al’s “Performance of Thermal Insulation on the Exterior of Basement Walls” [NRC Construction Technology Update No. 36]). EPS insulation installed as exterior insulation on a basement wall was monitored over a 30-month exposure period. In-situ thermal performance of the EPS insulation, site weather conditions, and soil moisture content were instrumented and monitored throughout the project.

The in-situ thermal performance of the EPS exposed to soil backfill was monitored using thermal couples attached to the insulation and concrete basement wall. The monitoring indicated the EPS’ thermal performance remained stable and was not adversely affected by water movement in the soil in contact with the insulation.

Material properties were also determined for EPS insulation removed after the 30-month exposure. Testing confirmed all types of EPS in the research program retained their specified thermal and mechanical properties even after being subjected to in-situ freeze-thaw cycling. The moisture content of EPS insulation removed after the 30-month exposure was in the range of 0.01 to 0.96 per cent by volume.

The NRC-IRC research project identified the following key EPS insulation performance attributes:

- The average moisture content of EPS insulation directly exposed to high-MC soil conditions was found to be less than 0.5 per cent by volume at the end of the exposure.

- In-situ thermal performance of the EPS insulation remained constant (i.e. there was no loss in thermal resistance) during the monitored exposure period.

- Laboratory test results from samples removed after the exposure confirmed thermal performance and durability (i.e. there was no change in material properties).

A second part of the research project included development of a laboratory test protocol that subjected test materials to extreme thermal gradient and environmental cycling—including freeze-thaw cycling—to assess durability. (See N. Normandin et al’s “Development of a Draft Test Protocol for Evaluating Durability Under Environmental Cycling of Insulation Products for Exterior Basement Applications” [NRC Report No. 3132.2, 1999]). Laboratory testing performed by NRC-IRC on samples from the same manufacturing lot of material subjected to the 30-month field exposure confirmed all types of EPS insulation retained their specified material properties even after being subjected to the laboratory durability test protocol.

The draft test protocol from this project has been subsequently developed into ASTM C 1512-10, Standard Test Method for Characterizing the Effect of Exposure to Environmental Cycling on Thermal Performance of Insulation Products, to provide a means of assessing durability performance of all insulation types. The test method was originally published in 2001; ASTM Interlaboratory Study 44 was later conducted to establish a precision statement for C 1512 and the test method was re-published in 2010. (See the 2009 ASTM Research Report No. C16-1036, “Research Report to C 1512 Standard Test Method for Characterizing the Effect of Exposure to Environmental Cycling on Thermal Performance of Insulation Products.”)

Drainage properties

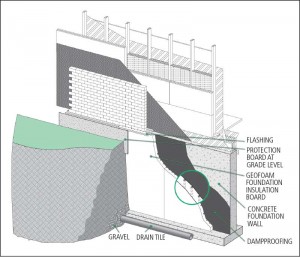

The monitoring of in-situ thermal performance during the NRC-IRC research project discussed earlier detected the presence of water at the outer surface of the EPS insulation during periods of heavy rain and major thaws; however, the surface of the concrete basement wall showed no evidence of water penetration through most of its height. This demonstrated that when used as below-grade foundation insulation, the EPS surface acts as a capillary-breaking layer. The insulation’s surface resists water penetration and provides a drainage plane. If adequate provision for drainage is provided at the base of the wall, water not removed at the ground surface drains to this location.

Geofoam applications

EPS geofoam is supplied in the form of either blocks or boards. Construction is rapid—depending on the application, products are usually installed on delivery without requiring onsite stockpiling or storage. Individual EPS geofoam blocks or boards can be lifted by construction equipment or placed manually by a work crew.

As indicated, EPS geofoam has been used successfully for a wide range of geotechnical applications. Figure 4 identifies numerous applications and highlights some of the typical design considerations.

Foundation insulation

EPS insulation applied to the exterior of foundation walls ensures the concrete is not subject to expansion and contraction caused by temperature differences between the interior heated space and the exterior air/soil temperature. The EPS R-value on the exterior of the foundation reduces the likelihood condensation will form on the concrete wall’s inner surface, which would be at room temperature.