Specifying building wrap for moisture management and drainage

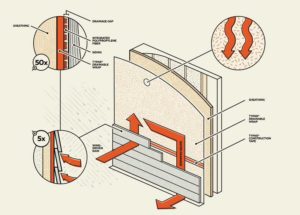

Rainscreen products are recommended in areas with wind-driven rain, extreme amounts of rainfall (1016 to 1524 ml [40 to 60 in.] annually), or elevated temperature and humidity. Coastal areas and hilltop exposures are prime examples of when this technology would be ideal. In these situations, the importance of creating a drainage plane is heightened when using absorptive cladding material such as wood or fibre cement.

Wraps with spacers or dimples

Another approach gaining popularity is the incorporation of unique spacers, or dimples, onto the building wrap itself. These drainable building wraps can achieve a 1 mm (0.039 in.) drainage gap through a pattern of integrated spacers and can be as much as hundred times more effective than standard building wraps at removing bulk water from the wall. Most can be installed in any direction without affecting performance. These products are recommended behind wood, fibre cement, vinyl, stone, and stucco cladding, or where budgets do not allow the use of a full rainscreen system.

Integrated fibrous layer

The forefront of drainable building wrap technology are products that create a drainage gap through a layer of polypropylene fibres. The drainage gap created by this technology has been shown to achieve 94.8 per cent drainage efficiency, as per ASTM E2273, conducted by a third-party lab, without sacrificing any of the durability and ease of installation benefits that builders and contractors expect from premium building wraps.

Similar to dimpled wraps, these products can also be installed in any direction without affecting performance. They are also vapour permeable, so moisture will not be trapped in the wall assembly and lead to moulding or rotting issues.

Conclusion

A growing preference for reservoir claddings and new developments in building codes have resulted in specifiers taking a closer look at moisture management and drainage strategies. Each project is different, and with myriad of building wraps available, alongside sheathing and cladding materials, managing water intrusion and vapour drive can be a complex equation to solve. However, the specification process is made easier with a greater understanding of how these components can work together to balance drainage and offer breathability to the wall, while potentially reducing material costs and helping to keep projects on-schedule and on-budget.

Notes

1 Refer to “BSI-112: Drain the Rain…On the Plane…the drainage plane*” by Joseph Lstiburek. Visit buildingscience.com/documents/building-science-insights-newsletters/bsi-112-drain-rainon-planethe-drainage-plane.

Author

Bijan Mansouri is the technical manager at TYPAR Construction Products. He has been with Berry Global for nearly 30 years, working in different technical capacities. Mansouri is responsible for building code requirements, the design and development of new construction products, training builders and architects on application of new and existing products, and creating and educating on the proper practices and installation of building envelopes. He can be reached at bijanmansouri@berryglobal.com.