Snow guards and metal roofs 101

Snow guards on metal roofs

Metal roofs provide a unique and slippery surface for the adherence of snow. The following factors should be considered when determining what form of roof snow retention should be used.

Ground vs. roof snow

A common mistake when designing snow guard devices is using ground snow load in calculations rather than roof snow load.

Ground snow load is defined as the weight of snow on the ground surface, while roof snow load is defined as the weight of the snow on the roof surface used in the design of the building structure. Ground snow load values in Canada are established using data collected by Environment Canada.

If buildings were flat without any obstructions, ground snow loads would be similar to roof snow loads. However, this is rarely the case. Snow will collect on a roof in different depths based on various conditions and levels of roof design. Wind and shading are the deciding factors on how snow accumulates on a roof. Generally, the wind will create snow buildup against higher surfaces (e.g. walls and parapets), drifts on lower roof sections, snow accumulation deposits in roof valleys, and drifts on the leeward (downwind) side of objects, obstructions, and ridges, known as ‘aerodynamic shading’ (Figure 8).

These accumulations and drifts create an unbalanced load on roof surfaces that may not be accounted for in the ground snow measurement. Unbalanced loads could produce a roof design load of three or even four times that of ground snow. Hence, if a snow guard is engineered to resist only the ground snow load, it would most certainly fail under the added weight of the roof snow. Consequently, it is important to obtain the roof snow load calculation from the engineer and use it in the guard’s calculation.

Miscalculation of tributary snow loads

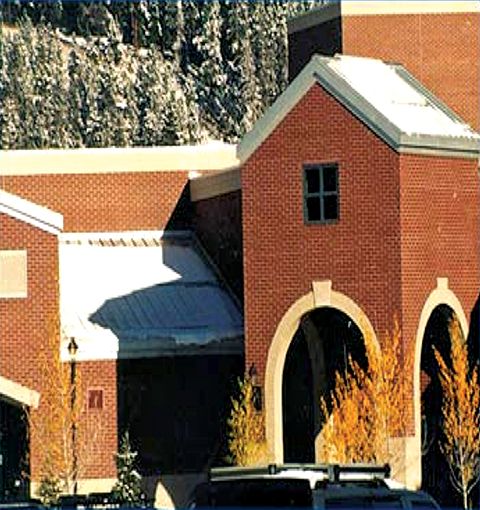

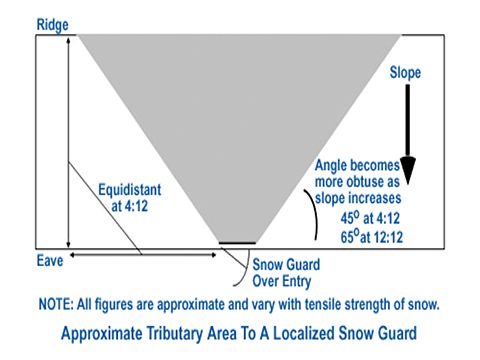

The miscalculation of localized tributary loads is another frequent error. For instance, if a designer wants to protect people using an entryway, rather than protecting an entire eave, he or she designs a small section of snow guard just over the doorway. The tributary area of snow buildup behind that snow guard is not a simple rectangular area as many would suppose. The snow retained will represent a wedge shape that far exceeds the vector forces of a narrow strip of snow guard. The side angle of the wedge shaped accumulation will grow more obtuse as the slope increases (Figure 9). For example, a roof with a 12:12 pitch will create a 65-degree angle wedge behind the strip of snow guard, whereas a roof with a 4:12 pitch will create a 45-degree angle wedge behind the strip of snow guard.

This ‘penny-wise/pound-foolish’ approach of only using a snow guard over doorways will invariably lead to overloading the small snow guard strip and tearing it from the roof surface. Snow guards are an inexpensive roof accessory designed to reduce the designer’s and owner’s liability and protect people and property. Extending the snow guard device across the length of the eave will more evenly distribute the snow load on the device, and when properly engineered, provide protection for the life of the roof. Trying to save a few dollars on this safety device may lead to bigger long-term problems.

Esthetic considerations

Designers are often disappointed with the look of bar, rail, pipe, or fence snow guard devices and opt for a clear plastic option to fit their snow control needs. Polycarbonate snow guard devices are perceived as an economic option and have the benefit of allowing the roof colour show through the device and blend with the roof. While adding plastic to the roof may seem a logical option as these devices look ‘clear’ in photos, the prismatic effect of the light striking the plastic surface makes them highly visible when placed on the roof. Additionally, these plastic devices are petroleum derivatives and do not stay ‘clear’ for long. The sun’s UV rays can turn them yellow after just a few years.

Another concern of designers is the additional cost they associate with painting a bar, rail, pipe, or fence snow guard to match the roof colour. Innovations in bar and rail snow guards have incorporated a strip on the matching metal roof into a track on the front of the device (Figure 10). This colour strip allows for the snow guard to accurately match the metal roof and blend it into the roof surface. The inserted metal strip is the exact same colour as the metal roof surface and will weather and look the same as the roof surface for the life of the roof. This metal strip also hides the balance of the snow guard components from view and eliminates the need and cost of painting the snow guard.

Fastener damage

An important consideration when designing and specifying snow guard devices is how they will be fastened to the roof surface. It is a primary concern to specify fasteners that work with the roof surface and do not violate the metal roof manufacturers’ warranty. Using mechanically attached devices versus adhesive attached devices will maintain the integrity of the roof manufacturers’ finish warranty. Additionally, employing the correct mechanically attached device will maintain the integrity of the roof manufacturers’ watertightness warranty.