Snow guard design considerations

Since snow loads on roofs vary according to geographical location (climate), site exposure, and shape and type of roof as well as from one winter to another, subsection 4.1.6 of the National Building Code (NBC) expresses the specified snow load, S, on a roof or other surface as the sum of two components—one being the product of a series of factors—multiplied by an importance factor:

Is = importance factor for snow load; Ss = ground snow load, in kPa, with a one-in-50 probability of exceedance per year; Cb = basic roof snow load factor; Cw = wind exposure factor; Cs = roof slope factor; Ca = accumulation factor; and Sr = associated rain load, in kPa. However, the rain load at any location on a roof need not be taken greater than the load due to snow (i.e. Sr ≤ Ss[CbCwCsCa])(consult “Structural Commentaries” in the National Building Code (NBC) User’s Guide 2015).

Snow loads should be calculated for every project requiring snow guards as each one will have varying factors affecting the loads. Calculating snow loads on a roof should never be dismissed or taken lightly.

Calculating snow loads

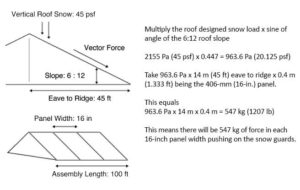

Figure 1 is an example of a snow load calculation based on a typical 24-gauge, 38-mm (1 ½-in.), single-fold standing-seam roof with 406-mm (16-in.) seam spacing. The roof in Figure 1 is 14 m (45 ft) eave to ridge, the roof-designed snow load is 2155 Pa (45 psf), the roof slope is 6:12 the seam spacing, or panel width is 406 mm.

The example does not take into account factors such as unbalanced snow loads, snow pileup, or upper roof snow shedding down to a lower roof. These factors must be considered when calculating snow loads, and are discussed in NBC 2015, Division B 4.1.6.2, Volume 1.

For the roof in Figure 1, there will be 547 kg (1207 lb) of force in each 406-mm panel width pushing on the snow guards.

With 547 kg of snow pushing on the snow guards there is still more work to be done. There is a multitude of snow guards on the market today, some use adhesive clamps to attach to the standing seam itself while others screw through the panel. It is easy to assume all the available snow guards work the same way, but this thought can lead to snow guard failure.

It is important to keep in mind some snow guard manufacturers use their ultimate load or failure point to design snow guards, which is not the best practice. For example, a snow guard manufacturer has load tested their attachment point to the standing seam, and determined the ultimate or failure point is 455 kg (1000 lb). Hence, they claim their attachment point to the standing seam can withstand 455 kg. This can lead to failures, as the ultimate or failure point of the load test was used. When a safety factor of two is applied to the ultimate load test, the allowable load would be 227 kg (500 lb), which is what the snow guard should be designed around. By applying a safety factor of two, the attachment point to the standing seam has a buffer, in case snow loads are higher in a given year.

To resist the loads imposed on snow guards it is recommended to install them the full length of the building as opposed to just over doorways, garage doors, or entrances. Isolating snow guards over doorways, garage doors, or entrances may overload them, or the snow may simply curl over the guard. When the snow slides down the roof and impacts the snow guard, it forms a wedge shape and can increase the initial snow load calculations, resulting in guard failure (Figure 2).

Budgets

As mentioned, snow guards are an integral part of the overall project when dealing with metal roofing, as they keep the snow from falling off the roof.

Typically, snow guards are an afterthought; they are missed during the initial scope of work. Sometimes, inadequate snow guards are used and need to be replaced. At this point, chances are the budget for the project has been spent and additional funds would be required to fix the issue, which means someone has to come up with more money, and that is never an easy conversation.