Sheathings reach beyond the code

In planning for construction, there are many areas of the air barrier system that require proper detailing to work effectively. Any leaky areas of the envelope can compromise the entire air barrier system. For example, wood and gas fireplaces and stoves can penetrate the air barrier where they vent, and sometimes where they are installed. To resolve problems such as this, wood frame walls should extend around all of these appliances, including around their chimneys and vents. This will provide numerous advantages beyond simplifying the air barrier system installation.

The building’s thermal insulation is substantially improved with the insulated house frame wall extending around the appliance, resulting in energy savings. Additionally, the approach keeps the flue of the appliance warm, improving venting for those appliances which rely on natural draft. When correctly installed, and with proper detailing, an EIAS system can provide many benefits.

Marketability in today’s industry

As a multifunctional system, it can also provide additional benefits to the homeowner. Cold drafts can be virtually eliminated in houses using this system, helping increase occupant comfort. The system provides long-term performance by using a mechanical seal to reduce the incidence of moisture-laden air leaking into insulated envelope cavities. When coupled to an efficient mechanical ventilation system, an EIAS system can enhance indoor air quality (IAQ). Further, this system can withstand wind loads typically encountered in a three-storey building. This helps ensure the air barrier system is effective over the house’s life and remains unaffected by extreme weather conditions. The improvement in energy efficiency results in lower heating and cooling energy costs.

Aside from the building science innovation associated with the system, it also promises to substantially reduce labour and material costs. There are numerous benefits for onsite installers when this type of system is used:

- the polyethylene vapour barrier does not need to be sealed;

- there are fewer penetrations to seal compared to polyethylene or airtight drywall (i.e. warm-side air barrier systems);

- it can be an effective weather barrier and sheathing membrane (building paper may be omitted); and

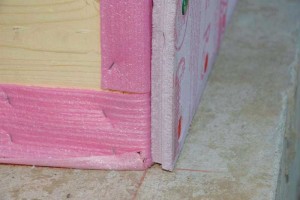

- the system uses commonly available materials, such as extruded polystyrene (XPS) wall insulating sheathing, polyethylene, and sill-plate gasketing.

The system results in a better performing wall assembly at a cost equal to or lower than that of a conventional assembly. For example, two options for reaching an R-24 (RSI-4.23) wall would be through regular R-19 (RSI-3.34) batt coupled with exterior insulating sheathing (R-5 [RSI-0.88]) or through high-density R-24 batt. In comparing these two assemblies, the EIS would result in a more cost-effective route. Properly installing an air barrier system requires attention be paid to all aspects of the building details. Good air barrier systems need not be costly or difficult to build, but they do require special care in ensuring the right materials are used and the system is continuous.

Reaping the rewards

The EIAS system offers the flexibility of different options to create an air barrier system customized to the builder’s needs. By maximizing envelope performance and cost savings, those implementing these systems are differentiating themselves as leading green competitors without introducing substantial changes to their production process. Builders are able to compare the performance of their standard production to different iterations of this new system, one house at a time. They are also able to identify the performance improvements that can be achieved.

Exterior insulating air barrier sheathing is a complete system that can help builders save time and money, and delivers durable, dependable comfort and energy efficiency to homeowners. As the government pushes to reduce GHG emissions and build a more sustainable environment, energy efficiency continues to be a priority. With the new provisions for housing and small buildings coming into effect, builders are responding by exploring systems such as the EIAS to help them reach beyond the requirements. Improving energy efficiency in buildings will continue to be a government priority to reduce carbon emissions. Exploring innovative building systems keeps design professionals at the forefront, ready to address and adapt to changes.

Janelle Day, B. Arch. Sc., is the technical co-ordinator at Lio & Associates. She currently works with builders to evolve exterior insulating air barrier sheathing (EIAS) into a system completely tailored to each builder’s production methods and trades. Day’s work with mentoring is helping to identify the differences in construction and the improvements in performance that can be achieved. She can be contacted via e-mail at support@mlio.ca.