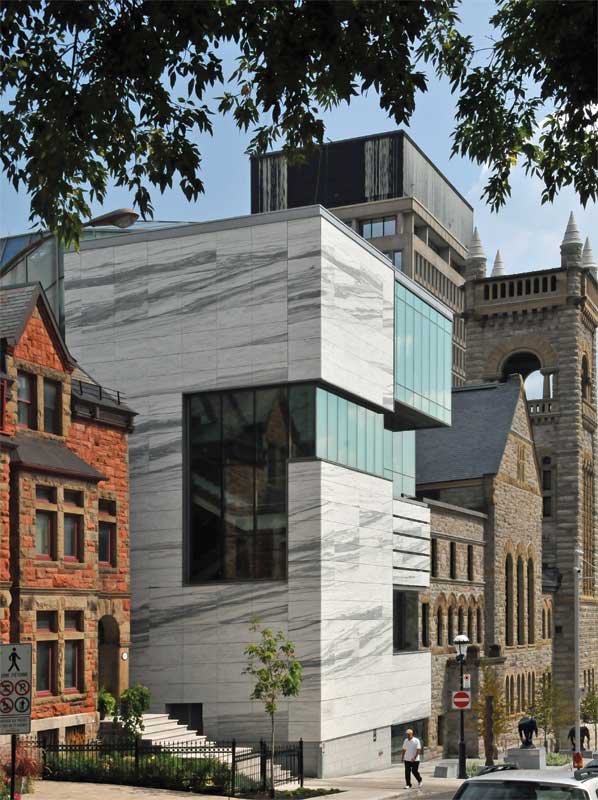

Selecting external stone cladding material

Photo courtesy National Tile

The specification process

When possible, it is valuable to solicit the supplier, fabricator, and installer’s participation when one is specifying stone for exterior cladding. This team can give the best direction for success. The team needs to understand and work within the tolerances provided by the stone fabricator. Fabrication capabilities and manufacturing tolerances will be the key to selecting the stone, sizes available, joint spacing required, and acceptable colour variations (if any).

Tolerances

Whether it is the manufacturing tolerances of the fabricator or the installation tolerances of the setter working on the site, these limitations must be factored into the overall result. Understanding and planning for these required tolerances will help alleviate onsite surprises and headaches.

Manufactured stone can vary in thickness; even smooth-honed and polished finishes can vary ± 0.8 mm (1/32 in.) from piece to piece in 10 to 15-mm (3/8 to 5/8-in.) thick material. Smooth-finished material 15 to 30 mm (5/8 to 1 1/8 in.) thick can vary ± 3 mm (1/8 in.) in thickness from piece to piece. More heavily textured finishes (e.g. flamed and heavy mechanical texturing) can vary 5 mm (13/64 in.) or more, piece to piece, and still be within the industry standards for acceptable variation.

As with the thickness, there are also acceptable variations in rectangularity and planarity of manufactured stone tiles and panels. The overall squareness of the natural stone panel is defined as the rectangularity. Planarity refers to the flatness of the stone. The ideal working material should be both square and as flat as possible. However, ‘square’ is not clearly defined in the current industry guidelines. It must therefore be a negotiated tolerance between all parties, including the specifier, supplier, quarry, and installer when the stone is ordered from the factory.

The flatness is defined in current Terrazzo, Tile, and Marble Association of Canada (TTMAC) manuals. As an example, it is considered acceptable if a stone tile up to a 600 x 600-mm (24 x 24-in.) size has a variation no more than 0.8 mm across 600 mm; for larger cut-to-size pieces, a variation of less than 1.5 mm (1/16 in.) across 1200 mm (48 in.) is considered ‘flat.’

Installers also have a set of industry standards and tolerances to which they adhere. These standards govern lippage from piece to piece (for smooth finished, 0.8 mm is tolerable) and the joint width spacing (±25 per cent of the specified dimension), to name a couple.

What happens when the plan is not made or understood? Recently, this author’s firm supplied a stone with manufacturing tolerances of ±0.5 mm (1/64 in.) for both rectangularity and planarity sizing. The installers had agreed to a 1-mm (1/32-in.) joint spacing as requested by the owner. The tiles were requested to be square-edged with no bevelled edges. The installer has had huge issues with chipping along the edges when the stones were placed so tightly together. These chipping problems were caused by sharp corners knocking together due to the joints being too tightly spaced. Also as a result, the tight joints the evenness of joint spacing started to creep, resulting in unsightly misaligned joints.

This was made even more problematic when the installers failed to use gloves when handling the stone for installation. The natural oils from their hands left marks requiring a special cleaning and spot removal process. Overall, it was a very expensive lesson for the installers. To be successful, this type of installation requires at minimum a 2-mm (4/5-in) wide joint space for stone, and installers should always wear gloves when handling natural stone.

It is recommended to follow all the TTMAC industry manuals’ including 093000 Tile and Stone Installation Manual, the Dimensional Stone Guide, and Hard Surface Maintenance Guide. Additionally, the ongoing co-operation of all concerned parties is paramount for a successful outcome.

Conclusion

Understanding all the parts that have to work together for success is not an easy or simple task. Since many players, including a stone consultant, need to be on this team, working with experienced stone-installers and partnering with educated suppliers will make the selection, supply, and execution process better. When comparing the various stone options, a basic understanding and review of test data will provide the information and understanding of which stone will meet the desired expectations. Suppliers and stone installers are available to help with this review. They will be your rock for when you are in a hard place.

Bill Wright is a technical specialist with Stone Tile International, and is currently heading its training and education department. He brings three decades of experience in all aspects of the tile and stone industry, from installation and manufacturing to architectural/contractor sales and management. For the past decade, Wright has served as a director of the Terrazzo, Tile, and Marble Association of Canada (TTMAC), where he was a regular contributor to the last three editions of the TTMAC Installation Manual. He can be reached at bwright@stone-tile.com.