Saving energy through air filtration

Gas-phase air purification and ASHRAE’s IAQP

The Indoor Air Quality Procedure provision has been added to AHSRAE 62.1 and gives gas-phase air purification an entirely new scope beyond purifying outdoor air of gaseous contaminants. Specifically, building owners now have the ability to reduce the outdoor air cubic feet per minute (cfm) per person.

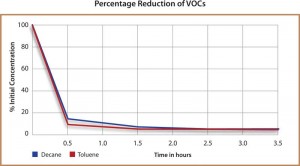

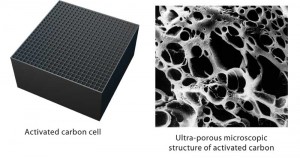

Gas-phase air purification has been used for decades in heavy industries such as petrochemical, wastewater processing, and paper/pulp to minimize process-generated gaseous contaminants affecting equipment, electronics, employees, and the surrounding environments. More recently, engineers have specified gas-phase air purification in HVAC system retrofits and new equipment as a result of the IAQP provision. During the gas-phase process, the air stream is directed through activated carbon, which is a porous material with the capability to adsorb most volatile organic compounds (VOCs). The carbon changes the contaminants from a gas to a solid phase.

Gas-phase air purification can remove chemicals that particulate filters, such as conventional pre- and final-filter media commonly used in HVAC systems, and even higher capture methods such as high-efficiency particulate arrestor (HEPA) and ultra-low particulate arrestor (ULPA) filters.

The original ASHRAE 62.1 was considered a superior advancement for indoor air environments. It prescribed the ventilation rate procedure (VRP) of flushing out indoor contaminants. Whereas VRP was the status quo for engineers over the last few decades, IAQP is expected to become a more favoured method.

VRP has two significant limitations that have become more critical due to today’s energy costs and environment:

- Outdoor air, depending on the season, must be heated, air-conditioned, and sometimes dehumidified before mixing with the air supply of a commercial building. This puts an extra energy burden on operating budgets.

- Outdoor air is typically more polluted than air inside a building. Therefore, introducing outdoor air needs additional filtration, especially in highly populated or industrial areas.

In light of these factors, IAQP may be a better methodology because its calculations are derived from ventilation, air-cleaning, and source control, whereas VRP only considers ventilation. Energy used to condition the outdoor air can be significant depending on location. For example, in winter, preheating –23 C (–10 F) outdoor air to 21 C (70 F) is a major expense even if it only accounts for 15 to 20 per cent of the supply air.

Summer operation can also be costly. A hot humid day of 32 C (90 F) requires cooling the outdoor air down to 24 C (76 F) and reducing the relative humidity (RH) to 55 per cent. ASHRAE 62.1 helped spur a growing outdoor-air-dehumidification equipment segment in the HVAC industry 20 years ago, because conventional air-conditioning equipment cannot always handle the high humidity loads of outdoor air in the summer.

The impurity of today’s outdoor air is also a factor. Outdoor air concentration of 0.14 m3/minute (5 cfm) per person might have been adequate decades ago when outdoor air was cleaner, but as the outdoor air has become more polluted with carcinogenic poly-aromatic hydrocarbons (PAH), benzene, and rising ground ozone levels, upgrades to 0.28, 0.42, and 0.57 m3/minute (10, 15, and 20 cfm) per person were seen as remedies to provide acceptable IAQ.

Even in areas with cleaner outdoor air, IAQ is affected by contaminants generated from indoor sources, such as cleaning chemicals, furnishings off-gassing, and other gaseous pollutants commonly found in buildings. When calculating the IAQP, engineers consider a variety of different parameters beyond the VRP. Potential outdoor air contaminants (based on government-funded research documents from many countries around the world) are included with off-gassing indoor air contaminants referencing the material safety data sheets (MSDSs) of building materials and furnishings, air changes, and other factors.

Once IAQP is calculated, the procedure allows for the addition of air-cleaning equipment to remove gaseous contaminants from both indoor and outdoor air. Ultimately, IAQP reduces the high outdoor air flow prescribed by VRP while simultaneously complying with ASHRAE 62.1.

Conclusion

The disadvantage of traditional gas-phase air purification is the fact its media must be periodically tested to determine the remaining adsorption capacity. Replacing media that has become 100 per cent adsorbed with contaminants is expensive.

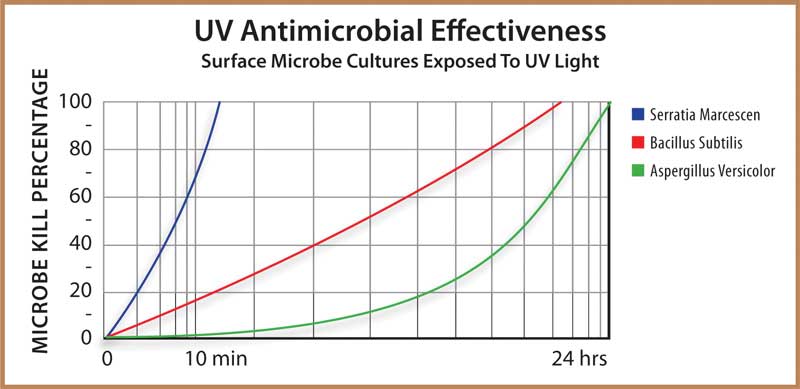

However, adding the PCO process can regenerate gas-phase media and negate periodic replacement, because it energizes a catalyst such as titanium dioxide, which is a popular coating infused into gas-phase media. The oxidization process of shining UV-C light onto the media degrades the adsorbed gaseous organic contaminants and can also oxidize bacteria and viruses.

When illuminated by UV light, the titanium dioxide produces hydroxyl radicals, which react with and decompose organic matter to mineralize, under conditions of complete oxidation, common gas-phase water molecules and carbon dioxide. Hydroxyl radicals are among the strongest oxidizing species and have stronger disinfecting capabilities than chlorine, ozone, and even hydrogen peroxide, while being much safer for building occupants. PCO destroys or mineralizes contaminants rather than simply sequestering them onto an adsorption substrate or media. Additionally, the PCO process requires no custom or artificially produced temperatures or pressures.

A good analogy of the PCO effect occurs naturally with beach sand and the sun’s UV rays. In the daytime, there are rarely foul odours, because the sun’s UV rays penetrate the sand and generate clean, oxidizing molecules. At night, without sunlight and its UV effect, ‘fishy’ odours dominate the air quality. Likewise, the same UV light used to disinfect the HVAC system’s interior surfaces, coils, and airstream, can also perform double duty by regenerating the carbon media and converting the adsorbed chemicals into harmless carbon-dioxide and water vapour. Therefore, the gas-phase carbon media is continually reused.

Advances in IAQ technology are bringing all three technologies—germicidal UV light, gas phase air purification, and photo catalytic oxidation—together into one cost-effective add-on unit for HVAC systems. Commercial building owners can now benefit by combining these three technologies.

Chris Willette is president of Fresh-Aire UV, a division of Triatomic Environmental Inc. He is an engineer and a designer/developer of indoor air quality (IAQ) products such as the Fresh-Aire APCO. Willette holds several patents/pending on ultraviolet (UV) lights and photocatalytic oxidation (PCO) for commercial and residential HVAC systems. He can be contacted via e-mail at chris@freshaireuv.com.