Freestanding roof guard woes

Staged structural failure analysis

A special procedure for this situation is called ‘staged structural failure analysis.’ The term derives from the concept of staged construction created by Computers & Structures Inc. This is a static modelling, analysis, and design application that enables the definition of a sequence of construction stages in which structural systems and load patterns are added or removed, and time-dependent behaviours are evaluated, including creep, shrinkage, aging, and tendon relaxation.

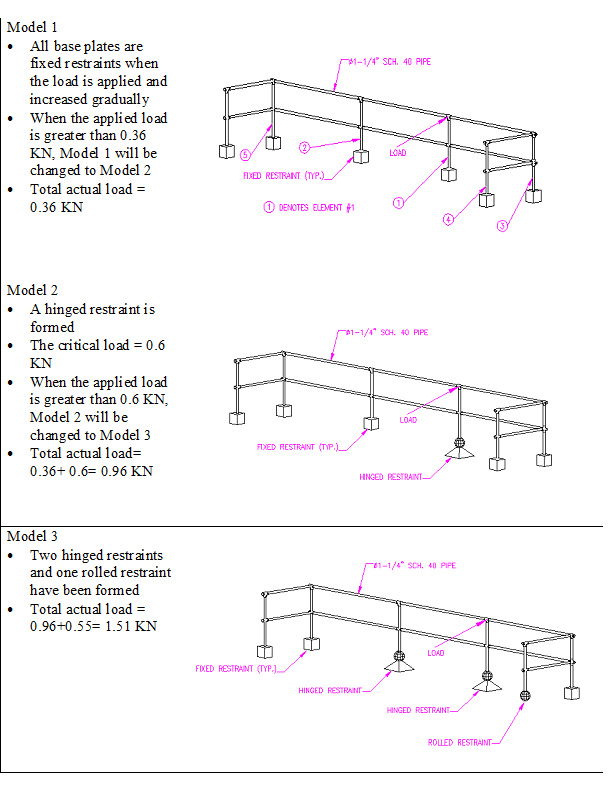

For the example discussed in this article, one model can simulate the whole restraints that are fixed, while another simulates one restraint that is hinged or rolled. However, one should know when the first model would switch to the second model—a trial-and-error method could be adopted to determine the maximum load withstood by the specific model.

The main procedures are described below:

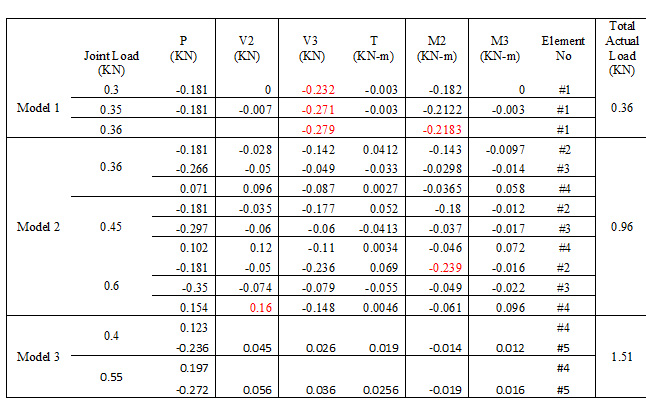

The detailed calculations are shown below to demonstrate the trial-and-error calculation methods step by step. The guardrail system’s three-dimensional structural analysis is conducted with SAP2000 v.15.

From this calculation table, one can obtain some helpful conclusions:

From this calculation table, one can obtain some helpful conclusions:

- Staged structural failure analysis can provide enough clues for how the system would fail step by step. From that, one knows where the system can be used.

- Model 1’s Element 1 shear force would reach its critical condition first—V3= −0.232 KN great than 0.222 KN—so the base plate would slide. If the base plate kept sliding, the whole system would collapse. Therefore, the guardrail system can only be used where a roof curb or low parapet on the leading edge of the roof is present. The base plates should be placed right next to the vertical rise of the said structures to eliminate possible base plate slide due to friction failure.

- Model 1 would change to Model 2 when the turn-over moment reaches its limit.

- One should always use an outrigger assembly at the beginning and end of a continuous run. (The outrigger is a strong frame which can significantly increase the stability of the systems.)

- Model 2’s Element 4 is subject to tension, which would reduce the friction force the base plate provides. The critical condition is the tensional force is big enough the horizontal shear force is equal to friction force. In this case, the base plate would slide.

- The guardrail system analyzed in this article is adequate to withstand a concentrated load of 1.0 KN specified in the Ontario Building Code, although the deflections and displacements might be much greater than general requirements.

Conclusion

Staged structural failure analysis is a practical method that can be applied to many cases where the structural systems and loads change. When engineers sometimes have to handle this kind of problem, the so-called staged structural analysis might provide an ideal solution.

Bill Yao, P.Eng., has been a civil/structural designer for 20 years. He currently works as a structural engineer in an engineering firm in Markham, Ont. He can be reached via e-mail at wyao03@yahoo.com.