Role of HVLS fans in disinfecting indoor air

Upper-room UVGI system performance benchmarks

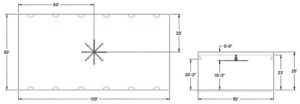

To ensure effective inactivation of airborne contagions, upper-room UVGI design guidelines are provided by NIOSH in partnership with CDC. The most important of these guidelines concerns the selection and positioning of the UV sources. The lamps should be arranged to provide irradiance in a uniform manner. Total UV fluence should be between 30 and 50 μW/cm2. This measure of radiation intensity can be multiplied by the duration of exposure (the time of an air particle in the disinfection zone) in seconds to determine the dose, measured in μJ/cm2. A suggested simplification of this principle is to use 0.18 watts of lamp power per cubic foot (0.18 W/cf) of upper zone air volume or 0.17 watts of lamp power per square foot (0.17 W/sf) of floor area.

Additionally, fixtures with louvers should be a minimum of 2 m (7 ft) above the finished floor, and fixtures without louvers should be at least 3 m (10 ft) above the floor. The minimum height requirements do not guarantee acceptable exposure at occupant levels. While exposure can be estimated in a simulated environment with specialty software, many models fail to capture the complex geometry and the true reflectiveness of every object in a facility. As such, it is recommended radiation levels be measured with calibrated meters to verify intensities are within NIOSH limits for an assumed occupancy duration.

Ambient operating conditions play an important role in the effectiveness of UV-C lamps. For unconditioned spaces in climates where relative humidity (RH) regularly exceeds 60 per cent, higher fluence densities may be required to achieve the desired performance. Likewise, low-temperature applications (below 20 C [68 F]) and scenarios where airspeeds near UV-C lamps exceed 1 m/s (200 ft/min) may cause a decrease in lamp output and require more fixtures than standard applications.

All of these factors combine to drive the system efficacy for upper-room UVGI installations. However, even systems with properly specified and installed fixtures will not perform optimally without being able to effectively circulate air between the disinfection and occupant breathing zones. A significant way to improve system efficiency is to increase the effective rate of air changes per hour (eACH), a measure of how much indoor air is being cleaned by the upper-room UVGI system and subsequently redelivered to the occupant breathing zone by utilizing low-speed ceiling fans to improve the rate at which indoor air is circulated between zones.

Using HVLS fans to improve upper-room UVGI performance

Studies show that in spaces without mechanical ventilation air mixing, the effectiveness of upper-room UVGI systems is modest (12 per cent) and relies only on convection patterns generated by heat gains induced by occupant and equipment sources at floor level. Spaces with mechanical ventilation can also suffer. This is especially true for facilities with high deck heights where systems with high airflow rates can struggle with air mixing and distribution. This issue is problematic during the heating season when the rate of illness among occupant populations tends to be the highest.

Research conducted by the University of Colorado and sponsored by CDC and NIOSH has shown the disinfection of room air requires 6 to 12 ACH, much more than the 0.5 to 2 ACH that is typically required for odour and carbon dioxide (CO2) control in ventilated spaces per ASHRAE 62.1 (See “Relevant Studies,” page 22).1 Bringing in this amount of outdoor air to a facility can have significant energy and equipment implications. By introducing HVLS fans, the volume of air that is actively cleaned in the disinfection zone is more frequently circulated back to the occupant level and replaced in the disinfection zone by air with a higher concentration of contaminants. By continually mixing the disinfection zone and occupant breathing zone air volumes, the effectiveness of the UVGI system is improved, thus increasing eACH. This reduces the concentration of contaminants in the space without the need for a three to six-time increase in outdoor air rates.

In the second stage of the aforementioned study with 12 per cent system effectiveness without air mixing, a ceiling fan was added to ensure air mixing in the space. While operating the fan at a moderate speed, the system’s effectiveness rose to 87 per cent. It is important to note circulating fans, whether operating in forward or reverse, can achieve effective kill rates.

According to a study published in Environmental Health Perspectives, increasing ACH and using a mixing fan enhances UV’s effectiveness in inactivating aerosols of the pathogen S. marcescens. This increase in ventilation rates and mixing of upper and lower air volumes led to a reduction in pathogens, resulting in a safer, healthier indoor environment.

HVLS application design guidance

Overall, the application process for integrating HVLS fans in upper-room UVGI systems closely resembles that of common destratification applications. The key exception is a large change in the desired number of air turnovers per hour (ATH) and how the turnover metrics for each scenario are defined. While a standard destratification application may target two total building air turnovers per hour (ATH) (i.e. total fan airflow versus total space air volume), UVGI applications should target a minimum of 25 zonal air turnovers per hour (zATH) between the upper air volume (disinfection zone) and the lower air volumes (everything below the disinfection zone). This calculation method better represents the efficiency improvement mechanism HVLS fans provide to UVGI systems and more accurately predict required fan quantities. Fans from industrial or commercial/residential product lines can be used, with the largest fan diameter meeting clearance requirements and integrated into the existing building systems being preferred. A UVGI design tool can be used to generate a minimum quantity of fans to meet the desired zATH levels given basic dimensions of the targeted area.