Rethinking the Residential Wall: Reducing the impact of thermal bridging and air leakage with wall assemblies

A solution

To increase the overall thermal performance by reducing air leakage, a layered system was developed that combines 2×4 framing with graphite-enhanced moulded rigid polystyrene foam insulation and closed-cell SPF. (The graphite acts as an infrared absorber and reflector, thus reducing heat loss due to radiation and improving the material’s thermal performance.) While eliminating the need for plywood or oriented strand board (OSB) sheathing and reducing lumber content, the wall construction manages to provide equal or better lateral load resistance when compared to a typical wood frame wall, which is fully sheathed with OSB.

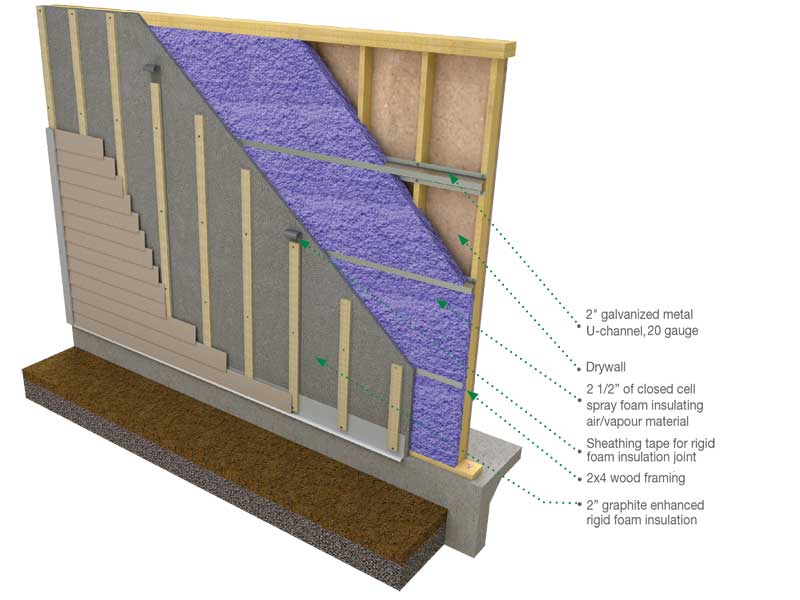

As shown in Figure 2, the assembly comprises:

- 2×6 bottom and top plates;

- 2×4 wood studs at 406 or 610-mm (16 or 24 in.) on centre (oc);

- 50-mm (2-in.) graphite-enhanced moulded rigid thermal foam insulation;

- a solvent-free sealant material compatible with foam sealant insulation;

- 63-mm (2½-in.) closed-cell SPF air/vapour barrier and insulation material;

- 20-gauge, 50-mm galvanized U-channel at 610-mm oc (installed horizontally); and

- extra room to add more insulation for an increased RSI value.

Material properties and positioning allow the wall’s overall thermal performance to be increased without encroaching on the interior square footage; it also helps fulfil additional building envelope functions, such as vapour, wind, and moisture control layers.

These types of systems have been tested by third-party laboratories and evaluated by an independent engineering firm. The energy performance of the total assembly is being assessed according to ASTM C1363, Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus. Air leakage is being assessed according to standard air barrier systems and air barrier materials (CAN/ULC-S741 and S742), while lateral, wind, and seismic load resistance must meet NBC’s Part 9 requirements.

Installation and other benefits to builders

As a system, these types of holistic wall assemblies can be easy to install because they do not deviate much from how contractors operate. Proper step-by-step training is offered to builders and sprayfoam contractors. Using these types of assemblies helps reduce the restrictions imposed by unfavourable weather conditions—the method permits an installer to spray an exterior layer of continuous foam insulation from inside the home.

One of the biggest challenges for builders is sealing the building envelope, especially in winter. This integrated system addresses the concern about applying sprayfoam in adverse weather conditions, making year-round installations possible. Pre-manufactured panels are also a possibility, offering choice and flexibility to builders. Durability and long-term adhesion of sealing tapes are not issues of concern.

Another benefit for builders is the reduction of callbacks. Experience gained through the U.S. Department of Energy’s (DOE) Building America program confirms high-performance homes have fewer callbacks.

Benefits to occupants

Ensuring customers are satisfied is important to the construction industry. Whether mixed-use tenants or condo dwellers, occupants are demanding better indoor air quality (IAQ), less noise, less dust, fewer drafts and cold spots, lower energy costs and reduced maintenance. They want a higher performing, more environmentally responsible space, but without having to spend a lot more for it.

“The ongoing consumption of energy to operate, condition, and light a building, as well as the energy embodied in ongoing maintenance, is the largest single source of environmental damage and resource consumption due to buildings,” said Straube.

With better control of heat, air, moisture and vapour flow, a high-performance envelope can help reduce energy bills. For many occupants, the important issue is day-to-day comfort. This wall assembly can translate into healthier living through its impact on the interior environment by, for example, improving IAQ and reducing dust and allergens that can be noticeable, especially for those with breathing conditions.

The wood frame aspect of the wall system is acceptable for all Part 9 construction, which includes uses other than single-family residential, such as business, personal services, and mercantile occupancies. To date, the wall system has been used mostly in single-family homes, but also for a few multi-family residential projects.

Rob Cardinal, B.A.Sc, MPM, has been working for thermal insulation manufacturers since 1985 and has been with BASF Canada since 2008. Experienced with residential, commercial, and industrial construction, from foundations up to roofs, he has designed, tested, and implemented air barrier systems for wood-framed buildings. Cardinal chairs the Spray Polyurethane Foam Task Group at Underwriters’ Laboratories of Canada (ULC), and is a member of the ULC Standards Committee on Thermal Insulation Materials and Systems. He is a member of the Standing Committee on Energy Efficiency in Buildings of the National Energy Code for Buildings (NECB). Cardinal can be reached via e-mail at robert.cardinal@basf.com.

Rob Cardinal, B.A.Sc, MPM, has been working for thermal insulation manufacturers since 1985 and has been with BASF Canada since 2008. Experienced with residential, commercial, and industrial construction, from foundations up to roofs, he has designed, tested, and implemented air barrier systems for wood-framed buildings. Cardinal chairs the Spray Polyurethane Foam Task Group at Underwriters’ Laboratories of Canada (ULC), and is a member of the ULC Standards Committee on Thermal Insulation Materials and Systems. He is a member of the Standing Committee on Energy Efficiency in Buildings of the National Energy Code for Buildings (NECB). Cardinal can be reached via e-mail at robert.cardinal@basf.com.