Restoration of aging masonry buildings

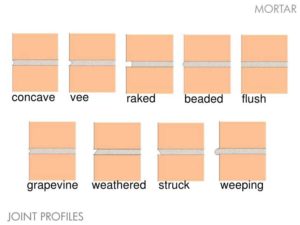

The joint profile of the mortar can also have a significant impact on the long-term performance of the brick masonry wall. Further, it is not recommended to base the selection of the joint solely on esthetics especially for buildings prone to wind-driven rain events. Figure 4 provides a snapshot of typical joint profiles. A slightly concave joint is ideal as it allows for the mortar to be installed with sufficient force to ensure compaction.

Best practice #2: Avoid raked mortar joint profiles in exposed exterior applications.

A raked joint may help create the desired look of a masonry wall. However, it is this author’s opinion the profile should be avoided in exterior locations unprotected by a canopy or similar rain-shedding features because it allows for rain and/or snow to collect on the top surfaces of the masonry units, thereby degrading the mortar bond line and increasing potential for moisture ingress as shown in Figure 5.

Brick masonry

Brick masonry units comprise the vast majority of the masonry assembly and have the largest impact on an exterior wall’s durability and esthetics.

Brick masonry is generally viewed in the design community as a durable material suitable for use within exterior, impact-prone environments. Masonry has a reasonable resistance to the elements, is ultraviolet (UV) radiation stable, and has desirable moisture retention and dispersion and fire-resistance properties. However, based on the quality of the materials used and installation methods, this brick masonry could also be susceptible to widespread cracking and spalling, thereby creating a public safety liability and financial burden for building owners.

Cracking

Photo courtesy International Masonry Institute

Cracking of brick masonry usually occurs as a means for relieving stress within brick enclosures due to differential movement. In this author’s experience, differential movement is often a result of settlement of the foundation or deflection of floor slabs. As the structure of the building moves, the cladding also needs to shift accordingly. If this movement is restricted, stress develops and will be relieved through cracks. In the case of brick veneer, this cracking follows the path of least resistance, typically along the mortar joints. However, as noted previously, cracking could also occur through the brick units if incorrect mortar is used. In the event of vertical cracking (i.e. cracking through a brick masonry unit) when an appropriate mortar was used, the cause was more likely localized and significant such as a point load placed on the brick veneer. Significant cracking may impact lateral connection of the veneer to the backup wall and should be investigated as soon as possible.

Images courtesy Pretium Engineering

To reduce potential for cracking, it is recommended to follow the guidelines of the Canadian Standards Association (CSA) A371, Masonry Construction for Buildings. It outlines locations and sizes for movement joints in brick veneer. Of particular importance are the movement joints below shelf angles of brick veneer. As floor slabs deflect due to dead and live loading between columns, the shelf angle attached to the floor slabs also deflects. This may result in the brick veneer below the shelf angle taking on unintended loading, leading to associated crack development (Figure 6). Rehabilitation at these conditions would be required to allow for the occurrence of differential movement without loading the brick veneer. It is advisable to supplement existing tie-backs of the brick veneer to the backup wall as required if the new control joints leave a portion of the brick veneer unsupported.

Best practice #3: Install movement joints within brick veneer at intervals and locations at a minimum as recommended by CSA A371.

If the cracking is determined to exist from differential settlement of the foundation, remediation of the foundation wall should be completed prior to repairing the cracking within the brick wall. Failure to stabilize the foundation first may result in further cracking of the brick masonry.