Reinventing Canadian masonry

The ease of application of the spray-applied GFRP makes this form of reinforcing an attractive option. However, fire safety concerns with the resin used to bind the glass fibres must still be addressed for interior applications.

Masonry research at universities also means the subject is likely to be available as a specific course. This provides exposure to design with masonry and tends to generate interest in masonry research with future architects and engineers. The more comfortable an architect or engineer is with a material, the more likely and willing he or she tends to be to design with it. In this regard, masonry research and the post-secondary education complement one another.

Education of professionals

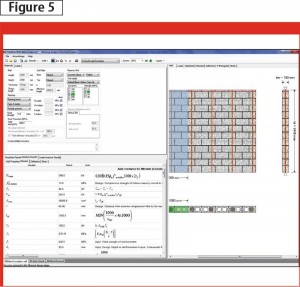

The masonry industry identified the need to invest in the education of architects, specification writers, designers, engineers, and masons. To facilitate design with these assemblies, state-of-the-art Masonry Analysis Structural Systems (MASS) software was developed and released in November 2010 through a joint partnership between CCMPA and the Canada Masonry Design Centre (CMDC). (Complimentary copies of MASS Version 1.0 are provided to designers within the regions of CMDC and CCMPA—Ontario, Alberta, Manitoba, Saskatchewan, and British Columbia. Visit www.masonryanalysisstructuralsystems.com).

This software analyzes and designs masonry beams, out-of-plane walls, and shear walls in accordance with the CSA masonry standards. One of the highlights of the MASS program is its highly visual graphical user interface, which depicts scaled drawings of the element being designed, including rebar location and spacing (Figure 5).

The software also makes it easier for designers to check their calculations by providing the equation accompanied by a reference to the appropriate clause in CSA S304.1-2004, Design of Masonry Structures, when a value is output. In fact, the output can be printed as a supplement to the designer’s notes; this reduces time and effort when analyzing and designing structural masonry elements.

The software can be used as a simple design check by selection of one block size and strength, and one rebar size and spacing or to generate the most optimal feasible design by cycling through thousands of combinations of block and rebar sizes, strengths, and spacing. The program is also structured to alert designers to possible “constructability concerns” to warn a designer that a particular solution that works on-screen may be difficult to implement onsite.

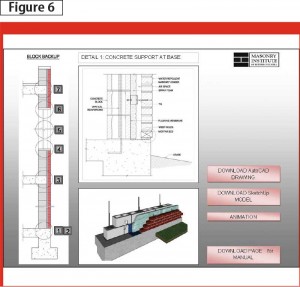

Other excellent design aids have been developed by the Masonry Institute of British Columbia (MIBC), including a technical manual as a free download from its website. (Visit www.masonrybc.org). This resource includes typical guide specifications in Microsoft Word format that can be used to reduce the work in generating specifications for unit masonry and masonry veneer, as well as state-of-the-art 3-D details in Sketch-Up (a free Google download) linked to a 2-D detail illustrating the unique cross-section (Figure 6) at various points along the elevation of a masonry veneer wall.

Also on the MIBC site is the digital edition of the 317-page authoritative Seismic Design Guide for Masonry Buildings by Donald Anderson and Svetlana Brzevand, developed through a partnership of the University of British Columbia (UBC) and the B.C. Institute of Technology (BCIT) on the design of structural masonry for seismic areas. The industry has made these useful tools and aids freely available to designers to encourage and simplify the effective design of masonry structures.

As mentioned, educating the design professional at the post-secondary level is an ancillary benefit of establishing research chairs and programs at universities across the country where the likelihood of an undergraduate masonry design course is much stronger than at universities without established research programs.

Mason education and certification

The masonry industry also recognized that to deliver an outstanding product, the people responsible for realizing the design had to be highly qualified. The construction quality had to maintain its high standards and match the quality of design intended to result from the MASS software, masonry design courses, and design aids available to design professionals.

The industry achieved this goal by investing in the education of its trades with a standardized apprenticeship textbook developed by the Canadian Masonry Contractors Association (CMCA) entitled, Textbook of Canadian Masonry, and by the continued development of CSA A371-04, Masonry Construction for Buildings. The objective of these authoritative references was to ensure a high level of competency from masons during their education and adherence to those high standards on the jobsite.

It is interesting to note that of the various wall construction trades, only masons and glaziers have (optional) certification programs and many of the local contractor associations require their members to employ certified masons.

Resurgence of interest

The benefits of masonry are being recognized once again, especially in locations across Canada where less expensive and unproven materials have failed to deliver the same durability, and moisture and fire-resistance as masonry. An excellent example of this is in the Vancouver area where a recent article in the Journal of Commerce identified an increase in demand for multi-family residential buildings to be constructed using masonry after the so-called Leaky Condo Crisis in the late 1980s and ’90s demonstrated to home owners the limitations and expense associated with improperly installed face-sealed stucco. (See J. Sorensen’s Journal of Commerce article, “Leaky Condos Make Masonry Popular Again,” in the May 9, 2011 edition).

With the increase of awareness of the impact of construction on the environment, masonry is also being recognized as a green building material. Its modularity minimizes waste. Masonry is easily recycled whereby demolition and construction waste can simply be crushed and reused to manufacture new masonry units or, ideally, if the look of weathered brick is preferred, existing brick can be simply reused.

Masonry units can replace cement with recycled materials such as fly ash and blast furnace slag in the concrete products’ aggregates. Of course, masonry is durable and long-lasting, which allows buildings constructed of it to be retrofitted for reuse. As a result of these properties, the use of masonry can help a project achieve up to seven Leadership in Energy and Environmental Design (LEED) credits:

- Energy and Atmosphere (EA) Credit 1, Optimize Energy;

- Materials and Resources (MR) Credit 1, Building Reuse;

- MR Credit 2, Construction Waste Management;

- MR Credit 3, Resource Reuse;

- MR Credit 4, Recycled Content;

- MR Credit 5, Local/Regional Materials; and

- MR Credit 8, Durable Buildings.

Of course, even for projects not pursuing certification, the innovative research is reducing the impact of masonry on the environment.

Conclusion

Although the masonry industry continues to compete for market share against less expensive claddings, the benefits of masonry are once again being recognized. Research and education have made masonry more easily accessible for the design professional and, although already a highly green building material, masonry research is leading to even more environmentally responsible characteristics, increased versatility, and more diverse esthetics. Renewed commitment to improvement of design and construction by the masonry industry through the continued education of masons, education of design professionals, and innovative research keep masonry competitive in its exceptional quality. Although the last two decades have been a difficult time for the masonry industry, the next 10 years could allow the material’s myriad redeeming features to again make it the most attractive choice.

Mark D. Hagel, PhD, P.Eng., is the executive director of the Alberta Masonry Council. He holds bachelor’s degrees in actuarial science/applied mathematics and civil engineering, and a doctorate in civil engineering. Hagel was employed as a technical services engineer for the Canadian Concrete Masonry Producers Association (CCMPA) before moving on to the role of a building envelope engineer and structural engineer with the Calgary office of Halcrow Yolles. His thesis dissertation, “Service Life Prediction of Connectors in Masonry Veneer Wall Systems,” was heavily rooted in both building science and structural engineering. Hagel can be reached via e-mail at markhagel@albertamasonrycouncil.ca.