Reinventing Canadian masonry

By Mark D. Hagel, PhD, P.Eng.

For thousands of years, masonry has been the building material of choice in many regions, with an infinite number of possibilities of pattern and form. Brick and stone are durable materials that never go out of fashion; they have been used to construct castles and cathedrals, pyramids and great walls, schools and museums, hospitals and high-rises, bridges, roads, and fences.

Although masonry is often imitated (i.e. stamped and synthetic products), very few materials are as versatile and fewer still are as durable. Nevertheless, a noticeable decrease in the use of masonry was accompanied in the 1990s by the increased use of sidings, stuccos, and exterior insulation finish system (EIFS) claddings, along with replacement of the traditional brick fireplace with steel fireplace substitutes in Western Canada.

The stakeholders of the masonry industry in Canada recognized a solid investment was required to preserve their ‘share’ as emerging wall systems began competing in markets traditionally dominated by masonry. Fifteen years later, various industry initiatives, from education to technological innovations, are helping masonry make a comeback.

While numerous articles in Construction Canada have explored the nuances of specific masonry assemblies and detailing, this feature takes a broader view, examining the current state of the country’s MasterFormat Division 04 products and the impending future.

Innovative research

The masonry industry recognized its products had to become more innovative to compete with the emerging cladding systems. Research into such innovations was greatly aided with the establishment of chairs and centres of research excellence at post-secondary institutions to attract top researchers to the field of masonry.

Images courtesy Alberta Masonry Council

Over the past 15 years, the masonry industry across Canada has created two research chairs at McMaster University (Hamilton) and the University of Alberta (Edmonton), respectively, and a Centre for Masonry Design at the University of Saskatchewan. The Canadian Concrete Masonry Producers Association (CCMPA) is currently funding 15 universities across Canada. The results have been truly innovative.

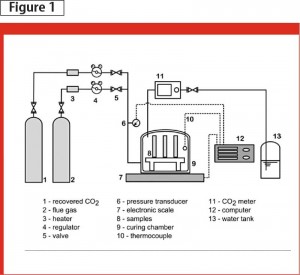

At Montréal’s McGill University, Dr. Y. Shao is investigating the reduction of carbon dioxide (CO2) emissions by up to 32 million tonnes annually in North America using CO2 recovered from the flue gas in cement production to cure concrete block and concrete pavers. Carbonation curing technology has been applied to the treatment of concrete blocks to reduce shrinkage by as much as 50 per cent under subsequent exposure to CO2 or wet-dry cycles. The process involves channelling CO2 recovered from flue gas to increase the carbonation rate (Figure 1).

According to Shao, concrete masonry units (CMUs) are ideal candidate products for carbon dioxide sequestration because “they are porous and are cured in a closed chamber with either low pressure or high pressure steam.” (For more information, see Y. Shao, S. Monkman, and A.J. Boyd’s “Recycling Carbon Dioxide into Concrete: A Feasibility Study,” a report presented at the 2010 Concrete Sustainability Conference—a National Ready-Mixed Concrete Association (NRMCA) event held in Arizona). For concrete block, CO2 absorption, by mass of cement binder, was 6.3 per cent.

As this research progresses, the result could be certain concrete masonry assemblies will be able to help projects passively reduce carbon dioxide in the atmosphere simply through carbonation, making them a very green alternative for architects, engineers, and specifiers.

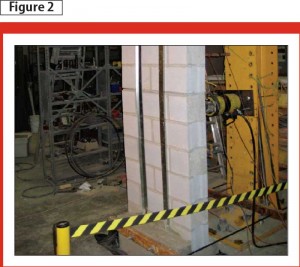

At McMaster University, Dr. R. Drysdale (co-author of the textbook Masonry Structures: Behaviour and Design) is investigating the use of hollow block foundation walls, externally reinforced with proprietary steel studs (Figure 2) to reduce cost in residential homes, which now require insulation and vapour barriers in basements under the National Building Code of Canada (NBC).

The testing demonstrated an ungrouted, unreinforced, concrete block foundation wall up to 3 m (9.8 ft) in height could be externally reinforced with proprietary steel studs and adequately resist the expected forces imposed by soil load on the foundation wall. The steel studs offer the dual function of reinforcing the block wall and providing the structure typically used to house services, insulation, and sheathing in basement walls. (See R.G. Drysdale et al’s “Arching Concrete Block Basement Walls: Tests,” delivered at the 11th Canadian Masonry Symposium, held in June 2009).

These steel studs eliminate the redundant wood or steel studding currently installed on foundation walls that house services but provide unnecessary structure; they would also eliminate the need for the internal vertical reinforcement and grout required in traditional reinforced masonry foundations.

By using a design guide, the structural design of these foundations will be simple and prescriptive in nature, without need for any detailed engineering calculations or atypical constructions. To offer flexibility, design professionals will be able to readily account for varying foundation heights, soil loads, and backfill heights. Similarly, onsite inspection for compliance is made easy and convenient.

The results may be a change to Part 9 of NBC to incorporate this dual-functioning technology. In addition to the benefits already acknowledged for CMU foundation construction, the technology offers a reduction in labour, material, and environmental costs to build masonry foundations having interior furring and finish.

Dr. W. El-Dakhakhni—McMaster’s Martini, Mascarin, and George Chair in Masonry Design—is also working with this technology, researching the possible use of this external steel stud reinforcement to retrofit unreinforced block walls against blast loads. (See B.M. Abou-Zeid et al’s “Performance of Unreinforced Masonry Walls Retrofitted with Externally Anchored Steel Studs Under Blast Loading,” an article in the 2010 edition of the American Society of Civil Engineers’ ASCE Journal of Performance of Constructed Facilities). With the recent increase in bomb attacks on buildings, the Canadian Standards Association (CSA) is developing CSA S850, Design and Assessment of Buildings Subjected to Blast Loads, to provide techniques to mitigate building damage during a blast event. Several government buildings are under investigation for retrofit against this type of loading and this technology may provide another alternative to architects, engineers, and specifiers when retrofitting unreinforced masonry buildings.

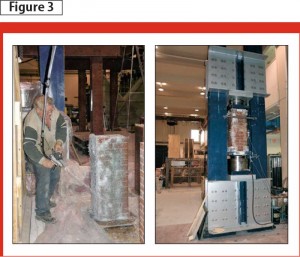

At the University of Alberta, Dr. Y. Korany (co-author of the textbook, Masonry Design for Engineers and Architects, and the school’s MCAA Chair in Masonry Systems) is experimenting with high-performance mortar using nano-silica, while at the University of Calgary, Dr. N. Shrive is investigating the use of spray-applied glass fibre-reinforced polymer (GFRP) to retrofit brick columns. (See E.B. Shaheen and N.G. Shrive’s “Sprayed Glass Fibre-reinforced Polymer Columns Under Concentric and Eccentric Loading,” in the May 2007 Canadian Journal of Civil Engineering).

The GFRP-wrapped brick columns experienced a 17 to 20 per cent increase in strength capacity and a 63 per cent rise in strain capacity on 390 x 390-mm (16 x 16-in.) concentrically loaded columns (Figure 3). This research concluded spray-applied GFRP is a relatively easy technique to provide significantly escalated strain capacity and small increases in strength for concentrically loaded masonry columns.

Shrive recognized this technology could also be applied to concrete block walls (Figure 4). Similar to Drysdale’s research at McMaster, the GFRP can be spray-applied to unreinforced, ungrouted concrete block walls as a substitute for traditional grouting and steel reinforcement in concrete block foundation walls. The peak load capacity was more than seven times that of the unsprayed wall and the resulting deformation was just less than five times the deformation of the plain wall at peak load, indicative of the increase in stiffness. (See M.A. Haddad et al’s 2007 CJCE piece, “Strengthening of a Concrete Masonry Wall Subject to Lateral Load with Sprayed Glass Fibre-reinforced Polymer: Part I, Experimental Tests.”)