Protecting buildings with hydrophobic coatings

by arslan_ahmed | April 18, 2023 10:00 am

[1]

[1]By James Howell

Water intrusion causes significant problems for buildings and must be prevented from damaging the structure. The building products industry is continuously looking for new technologies to assist with the prevention of water damage. Nature, as a notorious problem solver, often inspires solutions within the industry.

Complete prevention of water intrusion is important for buildings. The surface area of many buildings is covered by paint and coatings, some of which are made to withstand extreme weather conditions, therefore new technology is very much needed in this category. Hydrophobic acrylic coatings are using new technology to repel water. These types of coatings were inspired by the waterproof properties of the lotus flower.

The lotus flower is native to Southern Asia and Australia, and it roots itself in the mud and stretches up to the top of the water, producing lush blossoms. As it rises from the mud without stains, lotus often symbolizes purity. Since it blooms at the break of the day and returns to the water each evening, the flower is also known to signify strength and resilience.

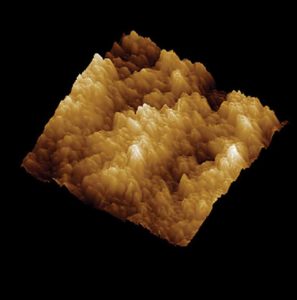

The leaves of the lotus plant are coated in a wax, which helps keep the plant waterproof and clean. The leaf’s microstructure consists of tiny wax pillars which are less than 100 microns apart. Water, which has a high surface tension, cannot penetrate through the tiny pillars and into the leaf. This creates a hydrophobic effect, forcing moisture and condensation to bead up and roll off the leaf. As the water beads roll off, they pick up dirt particles, keeping the lotus leaves clean and dry—this is referred to as the “lotus effect.”

For the last two decades, the building materials industry has looked for building performance improvements and sustainable solutions which mimic biological processes.

Construction stakeholders, such as architects, designers, specifiers, and building owners, are always looking to improve the durability of products. One of these advancements includes products which mimic the microstructural properties of the lotus leaf to create a super-hydrophobic water-shedding surface. Compared to typical acrylic systems, the use of hydrophobic technology increases the lifespan, and improves the water-shedding performance of the exterior finish or coating of the building.

The lifespan of hydrophobic coatings

In comparison to the two- to three-year lifespan of traditional architectural coatings without water-shedding properties, hydrophobic products can maintain their original clean appearance for seven to 10 years. Traditional coatings can typically offer substrate protection beyond two to three years; however, they are limited in their ability to remain clean and offer enhanced fade resistance. For lighter colours (e.g. lightness values greater than 55), traditional architectural coatings start to experience noticeable dirt pick and fungal and algal growth, giving potential customers a poor impression. Fade resistance is also another key property of coatings. Hydrophobic products are typically formulated with silicone polymer technology, which provides longer durability than traditional acrylic coatings.

[2]

[2]Discussing permeability

Permeability is important topic especially with traditional coating and finishes. Permeable, also known as breathable, coatings and finishes allows for the walls to breathe, leading moisture vapour to flow out of the wall, instead of being trapped within the building enclosure. It is the degree to which water or water vapour can transport through a building assembly and out.

Some hydrophobic and super-hydrophobic products both have higher water vapour permeability than many traditional latex coatings. However, not all hydrophobic coatings are permeable. For traditional coatings, permeability can be a big concern because they absorb moisture, and ensuring moisture can get out of the wall system is important. In short, repelling water is preventing moisture from getting into the wall assembly and reducing the amount of water vapour trapped in a wall.

Another key factor is understanding what hydrophobic means and how it functions to protect wall assemblies. Simply put, hydrophobic means “water-fearing.” The level of hydrophobicity is determined by the contact angle made between a liquid-vapour surface and a solid surface.

[3] One of the most hydrophobic surfaces in everyday use is polytetrafluoroethylene (PTFE). In the kitchen, one can see a droplet of water will roll around a PTFE-coated frying pan. PTFE has a contact angle of around 105 degrees. Surfaces with a contact angle greater than 150 are called super-hydrophobic surfaces.

[3] One of the most hydrophobic surfaces in everyday use is polytetrafluoroethylene (PTFE). In the kitchen, one can see a droplet of water will roll around a PTFE-coated frying pan. PTFE has a contact angle of around 105 degrees. Surfaces with a contact angle greater than 150 are called super-hydrophobic surfaces.

Understanding super-hydrophobicity

The term “super-hydrophobic” has become the common nomenclature to describe any surface which easily repels liquids. Sometimes it is used accurately, but most times, it is incorrect. A super-hydrophobic coating has a greater contact angle than a hydrophobic coating. A hydrophobic coating only needs to have a 90 degree or greater contact angle; whereas a super-hydrophobic coating typically has a coating contact angle of greater than 150 degrees.

[4]To understand the basic ideas behind many super-hydrophobic surfaces, both in nature and artificial environments, consider a “bed of nails.” If a balloon is pushed against a single nail, the nail penetrates the skin of the balloon, making it pop easily. However, if there is a bed containing many closely spaced nails, the balloon can be pushed quite hard against the nails, and it will not pop. This is because pushing against many points spreads the force and reduces pressure.

[4]To understand the basic ideas behind many super-hydrophobic surfaces, both in nature and artificial environments, consider a “bed of nails.” If a balloon is pushed against a single nail, the nail penetrates the skin of the balloon, making it pop easily. However, if there is a bed containing many closely spaced nails, the balloon can be pushed quite hard against the nails, and it will not pop. This is because pushing against many points spreads the force and reduces pressure.

Many plants and animals have evolved to have surfaces with much higher contact angles than that of PTFE. In the case of plants, super-hydrophobic surfaces can be created through the deposition of wax towers, such as on cabbage leaves, or via hairs (e.g. on the leaves of Lady’s Mantle). For animals, it can be through the use of super-hydrophobic structures. This could be the “coat” which allows a water boatman to pass through the surface of a pond without getting trapped by surface tension, or the scale structure of a butterfly’s wing that stops them getting waterlogged in rain.

[5]

[5]Performance in design

Designing a new building or recoating or recladding an existing facility comes with expectations to deliver a long-lasting structure and comfort for occupants. Five factors which impact the performance of a building and the exterior coating:

- Mechanical action, such as abrasions, hail, swelling, and building movement. Extreme weather, such as hail, can damage the structure or cause abrasions which compromise any coating applied to the exterior cladding.

- Air pollution, including organics such as nitrogen oxides (NO) and mineral materials such as dust. During wildfires, forest fires blow smoke and soot across the environment. In rural areas, fertilizers used on farms release nitrates into the air. In cities, hydrocarbon soot from diesel exhaust and jet exhaust leaves behind a sticky black residue. These pollutants can deteriorate the coatings and appearance of the facade.

- Biological organisms, such as mildew or fungal growth. In temperate rainforest regions, algae is common on the exterior of a building, creating an unappealing green appearance and decreasing the water-shedding effectiveness of the coating. In damp, humid climates, fungal growth can propagate and bond to coatings, making it difficult to remove and leaving a deposit on the surface of the coating.

- Bulk water includes rain, dew, snow, humidity, and other moisture and water vapour. The coating is the first face to the elements and requires effective, reliable water resistance. However, a traditional water-based coating can soften when exposed to bulk water. The softer coatings become tacky and attract dirt which does not wash away easily.

- Temperature and light effects due to climate and ultraviolet (UV) rays. Temperature and light can also degrade coatings on the exterior of buildings, making them fade after years of exposure. Moving North to South, the amount of UV exposure increases significantly.

Architects, designers, and specifiers can select from a wide variety of materials, finishes, and coatings to help protect a building’s exterior wall. The factors listed are important to different customers depending on their performance needs. This could depend on many different conditions such as climate, colour selection, or geographic location. A building owner in the downtown area, with a lot of vehicle traffic and high UV exposure, might prioritize air pollution over bulk water performance.

Acrylic coatings offer a variety of protective characteristics, including durability, fade resistance, and resistance to cracking, peeling, and chipping while bridging hairline cracks. They extend the lifetime of a building’s appearance and protect it from the elements. Applicable in new construction or a recoating situation, such coatings provide a variety of esthetic options and preserve the value of buildings by serving as a breathable, durable, attractive layer of protection.

Hydrophobic coatings are acrylic coatings which repel water. This enables faster drying of the surface, reducing the opportunity for mould, mildew, dirt, and other pollutants to grow or stick to the surface. They may be used for new construction or recoating existing buildings, and help the building maintain its esthetic appeal and perform better against the elements, while lowering maintenance costs and the frequency of recoating.

Having a super-hydrophobic or hydrophobic coating/finish, compared to a traditional one, can reduce building maintenance by as much as half or two-thirds of its original cost by extending recoat frequency and annual cleanings. In addition, by reducing mould, mildew, and algae growth on the surface of the coating/finish, it can also lower the chances of delamination or blistering—requiring less building repairs and possible moisture intrusion related issues.

[6]Though hydrophobic coatings offer several performance benefits, to mimic the self-cleaning capabilities of the lotus leaf, the coatings must be super-hydrophobic, as not all hydrophobic coatings are super-hydrophobic.

[6]Though hydrophobic coatings offer several performance benefits, to mimic the self-cleaning capabilities of the lotus leaf, the coatings must be super-hydrophobic, as not all hydrophobic coatings are super-hydrophobic.

The benefits of super-hydrophobicity

Super-hydrophobic materials possess a highly water-repellent surface, similar to a lotus leaf. Their microstructure mimics the lotus plant to minimize the contact areas for water and dirt.

Measuring the hydrophobicity of a material requires looking at the contact angle by placing a water droplet on the material’s surface. The advancing angle just as the droplet starts to move is the contact angle.

[7]

[7]The higher the contact angle, the higher the hydrophobicity. Higher hydrophobic materials will have less water on the surface and dry faster, leading to improved performance in critical factors, affecting the performance of the building’s exterior. This includes better freeze-thaw resistance, mildew and weathering resistance, UV protection, dirt collection capabilities, and staining resistance.

No matter which facade solution is selected, whether above-grade concrete, concrete masonry, exterior insulation and finish systems (EIFS), stucco, or previously painted wall surfaces, a coating or finish will be applied for added protection and esthetics. A hydrophobic coating offers additional armour and long-term value. With these applications in mind, super-hydrophobic coatings can help to enhance building performance in the following ways:

Durability

Coatings with rapid drying and water-shedding properties reduce maintenance costs and facility downtime. Enhanced water shedding products could last 10 years, compared to the average of two to three years for traditional coatings. This reduces the need for recoating, saving maintenance costs and improving operational efficiency.

Enhanced water shedding products can maintain their original clean appearance for seven to 10 years, compared to two to three years for traditional architectural coatings without water-shedding properties.

Traditional coatings can typically offer substrate protection beyond two to three years; however, they are limited in their ability to stay clean and offer enhanced fade resistance. For lighter colours (e.g. lightness values greater than 55) traditional architectural coatings start to experience noticeable dirt, fungal, algal growth and can give potential customers a poor impression of the business. Fade resistance is also another key property of coatings. Enhanced water-shedding products are typically formulated with silicone polymer additives, which provides longer durability than traditional acrylic coatings.

Safety and appearance retention

Hydrophobic coatings better resist mould, mildew, and algae growth and exhibit UV-stability and excellent weather resistance. This translates to a better long-term appearance, and an improved exterior which will not break down via long-term exposure to the elements.

Extended building lifecycle

Super-hydrophobic coatings provide reliable facade systems, materials, and assemblies, with more durable formulas and reduce the total cost of ownership. Over a two-decade installation, the super-hydrophobic coating has the potential to save almost 80 per cent in total cost of ownership over a standard coating product.

Some building owners have reported that with traditional coatings, they needed to pressure wash every one to three years. After recoating with s hydrophobic coating or finish, they have extended the time frame to five to seven years. This would be dependent on climate condition and geographic location.

The elimination of yearly pressure washing and the result of improved durability provide long-term savings over traditional architectural coatings (e.g. latex). Referring back to traditional coatings under the durability section of this article, the same properties contribute to extending a building’s lifecycle.

It must be noted, not all super-hydrophobic and hydrophobic coatings/finishes are created equal, which is why it is important to review product bulletins and data sheets. Performance properties, such as mould resistance, salt spray, freeze-thaw resistance, accelerated weathering, and water vapour permeability, are tested and commonly published. This criterion typically follows ASTM test methods or other industries standard testing procedures and is an indicator of performance and durability. One testing criteria critical to the performance of these products, but is often overlooked and seldomly published on data sheets, is the contact angle of super-hydrophobic compared to hydrophobic products.

Boosting cleanliness

Hydrophobic and super-hydrophobic technologies create low surface energy and non-polar structures. As previously mentioned, super-hydrophobic coatings have self-cleaning properties, and hydrophobic coatings are fast drying, and offer enhanced mould, algae, and mildew protection.

[8]

[8]Reclad delivers armour to condominium building

Along the Atlantic Ocean in North Myrtle Beach, the Edgewater Condominiums needed an upgrade to the 10-year-old stucco facade. The board of directors worked with the project team for the 10-storey condo building and made the decision to remove the cladding and install a continuous insulation (ci) wall system, with a super-hydrophobic finish which had self-cleaning properties.

“The hydrophobic finish does a remarkable job at keeping the building looking clean and new,” says Chris Rush, president of the Edgewater Condominium Associations (COA) board of directors. “The buildings completed more than a year ago [with the same finish system] looks just as good as the building that was just completed.”

The system featured a continuous, air and water-resistive barrier (WRB) which helps the building prevent moisture intrusion, but was also vapour permeable to allow quick drying. As added protection, the lack of fasteners in the adhesively applied continuous wall system further minimized potential moisture and air intrusion into the substrate.

Specifying a ci wall system helped to lower the utility bill by 20 per cent and improved comfort levels for residents. The water- and weather-resistant properties of the hydrophobic finish provided additional protection against damage and water intrusion during three hurricanes—Florence, Michael, and Dorian—which brought 120 km/h (75 mph) winds. What protects the building is the entire building enclosure and the finish layer provides the esthetics and protection against rain, but in the case of hurricane, there needs to specifically engineered wall systems that must meet strict criteria.

Makeover to defend resort hotel

The Steamboat Grand Resort in the popular ski area of Steamboat Springs, Colorado, sits at an altitude of 2,103 m (6,900 ft). The area has more than 300 days of sunshine per year and some of the highest snowfall totals in the state, wreaking havoc on traditional facades and water-based coatings. The climate conditions caused extensive damage to the roof, resulting in water intrusion, which led to the original facade being covered with mould and efflorescence. The original building cladding was stucco and exterior insulation and finish system (EIFS). After more than a decade, the exterior facade was worn by time and the weather and was in need of a facelift.

The 328-room resort hotel was the ideal location for a super-hydrophobic coating with self-cleaning properties. The project team could also apply the new coating without disturbing guests and visitors—an added benefit to the hotel’s operations.

Reliable armour

A building’s coating is its first line of defence; it is the initial layer of protection from the elements and human impact. Building owners, developers, and contractors can change the paradigm when it comes to long-term building performance and esthetic appearance by specifying more durable coating solutions, such as hydrophobic coatings.

With the cost of resources continuing to rise, architects and building owners continue to look for ways to improve building performance and extend its esthetic allure. By utilizing exterior finishes or coatings with hydrophobic technology, the cost of maintaining the visual apparency of a building can be greatly reduced.

Hydrophobic exterior finishes and coatings provide exceptional resistance to algae and mildew growth and can reduce maintenance costs by increasing cycle time between recoats. The ability to repel water contributes to increased weather resistance, reduced dirt pick-up, and added protection from wind-driven rain. Hydrophobic finishes or coatings keep the building looking good longer, perform better against outdoor elements, and can lower a building’s carbon footprint.

Verified standard testing has proven super-hydrophobic and hydrophobic products can repel water, increase weather resistance, reduce dirt pick-up, and provide added protection from wind-driven rain. As a result, it can keep buildings clean for longer and reduce the need to recoat.

Advancements in material science mean longer, more reliable coatings, which can resist the forces of nature, but at the same time, are inspired by that very nature.

[9]Author

[9]Author

James Howell is a product manager for Sto Corp. and focuses on on facade claddings. He has a degree in business management and has more than 20 years of experience working with exterior insulation and finish system (EIFS), stucco, air, and moisture barriers in research and development, and marketing departments.

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2023/04/Lotusan_Leaf_hi-res.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2023/04/Leaf-closeup-1.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2023/04/MG_4980.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2023/04/MG_5106.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2023/04/MG_5138.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2023/04/chateaugranville-before-5.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2023/04/chateaugranville-after-10.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2023/04/Kindstrom_SteamboatGrand-1.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2023/04/Howell_Headshot-REDUCED.jpg

Source URL: https://www.constructioncanada.net/protecting-buildings-with-hydrophobic-coatings/