Protecting buildings with hydrophobic coatings

By James Howell

Water intrusion causes significant problems for buildings and must be prevented from damaging the structure. The building products industry is continuously looking for new technologies to assist with the prevention of water damage. Nature, as a notorious problem solver, often inspires solutions within the industry.

Complete prevention of water intrusion is important for buildings. The surface area of many buildings is covered by paint and coatings, some of which are made to withstand extreme weather conditions, therefore new technology is very much needed in this category. Hydrophobic acrylic coatings are using new technology to repel water. These types of coatings were inspired by the waterproof properties of the lotus flower.

The lotus flower is native to Southern Asia and Australia, and it roots itself in the mud and stretches up to the top of the water, producing lush blossoms. As it rises from the mud without stains, lotus often symbolizes purity. Since it blooms at the break of the day and returns to the water each evening, the flower is also known to signify strength and resilience.

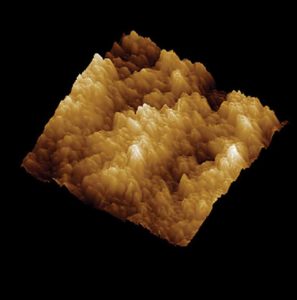

The leaves of the lotus plant are coated in a wax, which helps keep the plant waterproof and clean. The leaf’s microstructure consists of tiny wax pillars which are less than 100 microns apart. Water, which has a high surface tension, cannot penetrate through the tiny pillars and into the leaf. This creates a hydrophobic effect, forcing moisture and condensation to bead up and roll off the leaf. As the water beads roll off, they pick up dirt particles, keeping the lotus leaves clean and dry—this is referred to as the “lotus effect.”

For the last two decades, the building materials industry has looked for building performance improvements and sustainable solutions which mimic biological processes.

Construction stakeholders, such as architects, designers, specifiers, and building owners, are always looking to improve the durability of products. One of these advancements includes products which mimic the microstructural properties of the lotus leaf to create a super-hydrophobic water-shedding surface. Compared to typical acrylic systems, the use of hydrophobic technology increases the lifespan, and improves the water-shedding performance of the exterior finish or coating of the building.

The lifespan of hydrophobic coatings

In comparison to the two- to three-year lifespan of traditional architectural coatings without water-shedding properties, hydrophobic products can maintain their original clean appearance for seven to 10 years. Traditional coatings can typically offer substrate protection beyond two to three years; however, they are limited in their ability to remain clean and offer enhanced fade resistance. For lighter colours (e.g. lightness values greater than 55), traditional architectural coatings start to experience noticeable dirt pick and fungal and algal growth, giving potential customers a poor impression. Fade resistance is also another key property of coatings. Hydrophobic products are typically formulated with silicone polymer technology, which provides longer durability than traditional acrylic coatings.

Discussing permeability

Permeability is important topic especially with traditional coating and finishes. Permeable, also known as breathable, coatings and finishes allows for the walls to breathe, leading moisture vapour to flow out of the wall, instead of being trapped within the building enclosure. It is the degree to which water or water vapour can transport through a building assembly and out.

Some hydrophobic and super-hydrophobic products both have higher water vapour permeability than many traditional latex coatings. However, not all hydrophobic coatings are permeable. For traditional coatings, permeability can be a big concern because they absorb moisture, and ensuring moisture can get out of the wall system is important. In short, repelling water is preventing moisture from getting into the wall assembly and reducing the amount of water vapour trapped in a wall.

Another key factor is understanding what hydrophobic means and how it functions to protect wall assemblies. Simply put, hydrophobic means “water-fearing.” The level of hydrophobicity is determined by the contact angle made between a liquid-vapour surface and a solid surface.